OPERATION

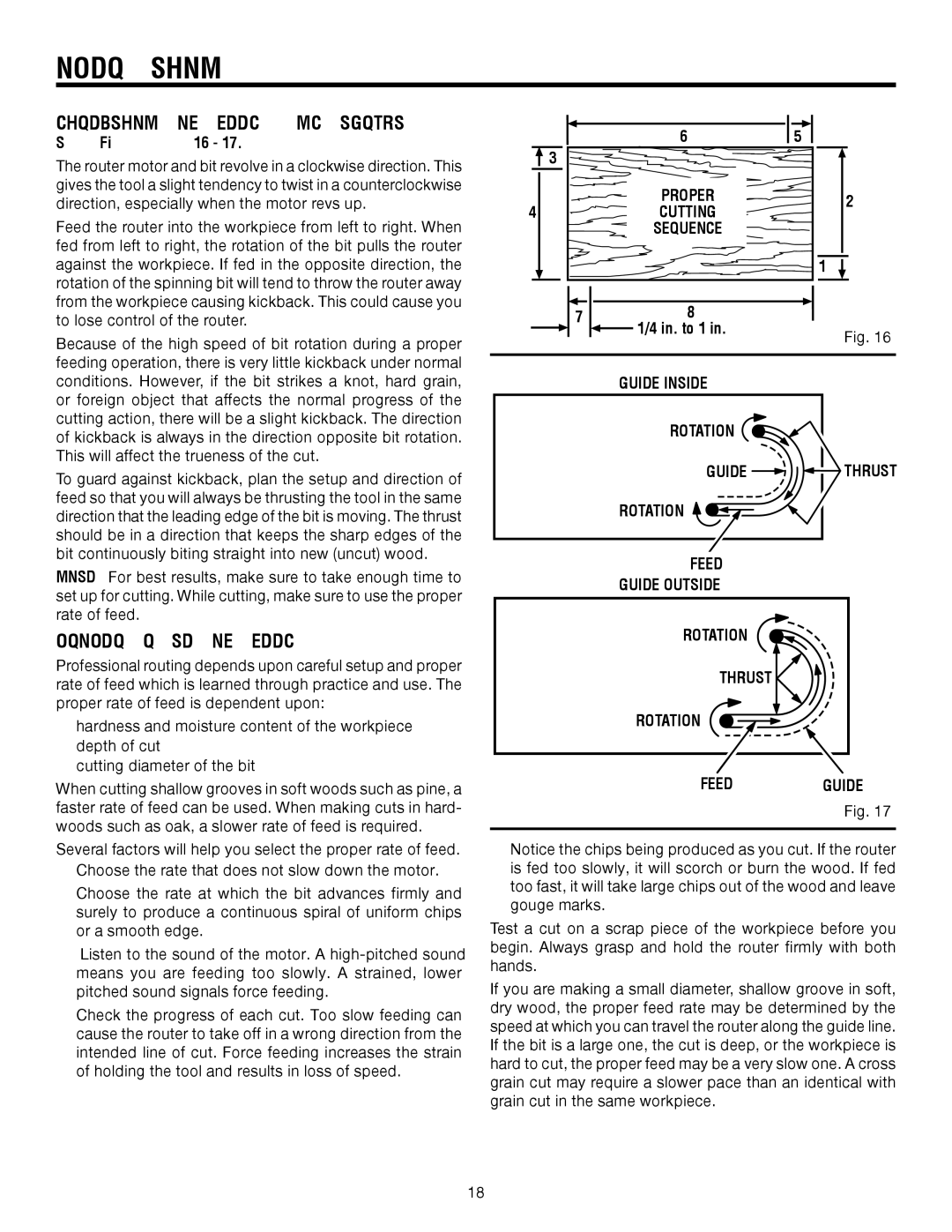

DIRECTION OF FEED AND THRUST

See Figures 16 - 17.

The router motor and bit revolve in a clockwise direction. This gives the tool a slight tendency to twist in a counterclockwise direction, especially when the motor revs up.

Feed the router into the workpiece from left to right. When fed from left to right, the rotation of the bit pulls the router against the workpiece. If fed in the opposite direction, the rotation of the spinning bit will tend to throw the router away from the workpiece causing kickback. This could cause you to lose control of the router.

Because of the high speed of bit rotation during a proper feeding operation, there is very little kickback under normal conditions. However, if the bit strikes a knot, hard grain, or foreign object that affects the normal progress of the cutting action, there will be a slight kickback. The direction of kickback is always in the direction opposite bit rotation. This will affect the trueness of the cut.

To guard against kickback, plan the setup and direction of feed so that you will always be thrusting the tool in the same direction that the leading edge of the bit is moving. The thrust should be in a direction that keeps the sharp edges of the bit continuously biting straight into new (uncut) wood.

NOTE: For best results, make sure to take enough time to set up for cutting. While cutting, make sure to use the proper rate of feed.

PROPER RATE OF FEED

Professional routing depends upon careful setup and proper rate of feed which is learned through practice and use. The proper rate of feed is dependent upon:

hardness and moisture content of the workpiece

depth of cut

cutting diameter of the bit

When cutting shallow grooves in soft woods such as pine, a faster rate of feed can be used. When making cuts in hard- woods such as oak, a slower rate of feed is required.

Several factors will help you select the proper rate of feed.

Choose the rate that does not slow down the motor.

�Choose the rate at which the bit advances firmly and surely to produce a continuous spiral of uniform chips or a smooth edge.

Listen to the sound of the motor. A

�Check the progress of each cut. Too slow feeding can cause the router to take off in a wrong direction from the intended line of cut. Force feeding increases the strain of holding the tool and results in loss of speed.

6![]()

![]() 5

5

| 3 |

| |

| PROPER | 2 | |

4 | CUTTING | ||

| |||

| SEQUENCE |

| |

|

| 1 |

| 7 |

| 8 |

| |||

|

|

|

|

|

| 1/4 in. to 1 in. | Fig. 16 |

|

|

|

|

|

| ||

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

GUIDE INSIDE

ROTATION

GUIDE | THRUST |

ROTATION

FEED

GUIDE OUTSIDE

ROTATION

THRUST

ROTATION

FEEDGUIDE

Fig. 17

Notice the chips being produced as you cut. If the router is fed too slowly, it will scorch or burn the wood. If fed too fast, it will take large chips out of the wood and leave gouge marks.

Test a cut on a scrap piece of the workpiece before you begin. Always grasp and hold the router firmly with both hands.

If you are making a small diameter, shallow groove in soft, dry wood, the proper feed rate may be determined by the speed at which you can travel the router along the guide line. If the bit is a large one, the cut is deep, or the workpiece is hard to cut, the proper feed may be a very slow one. A cross grain cut may require a slower pace than an identical with grain cut in the same workpiece.

18