MAINTENANCE

LUBRICATION

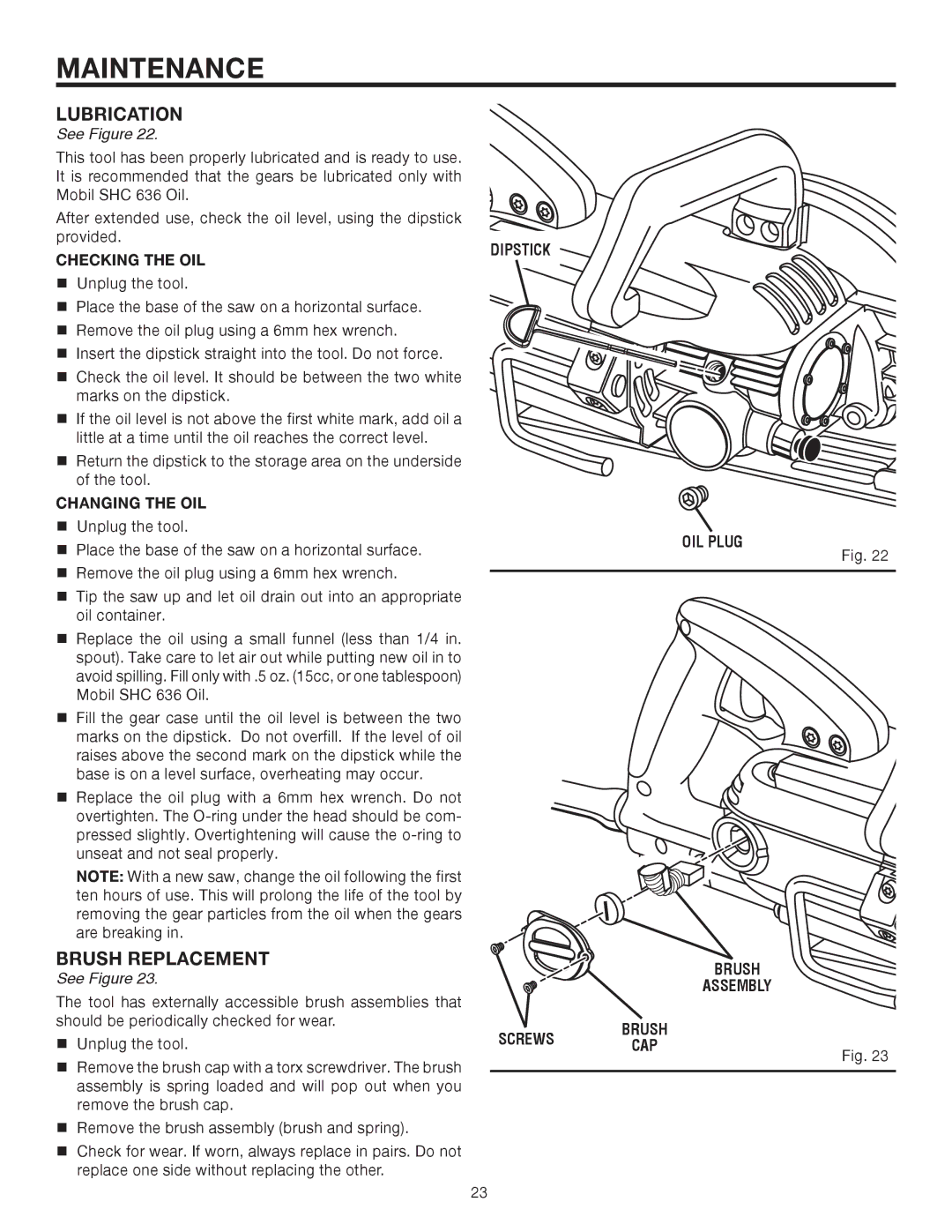

See Figure 22.

This tool has been properly lubricated and is ready to use. It is recommended that the gears be lubricated only with Mobil SHC 636 Oil.

After extended use, check the oil level, using the dipstick provided.

CHECKING THE OIL

Unplug the tool.

Place the base of the saw on a horizontal surface.

Remove the oil plug using a 6mm hex wrench.

�Insert the dipstick straight into the tool. Do not force.

�Check the oil level. It should be between the two white marks on the dipstick.

If the oil level is not above the first white mark, add oil a little at a time until the oil reaches the correct level.

Return the dipstick to the storage area on the underside of the tool.

CHANGING THE OIL

Unplug the tool.

Place the base of the saw on a horizontal surface.

Remove the oil plug using a 6mm hex wrench.

Tip the saw up and let oil drain out into an appropriate oil container.

Replace the oil using a small funnel (less than 1/4 in. spout). Take care to let air out while putting new oil in to avoid spilling. Fill only with .5 oz. (15cc, or one tablespoon) Mobil SHC 636 Oil.

Fill the gear case until the oil level is between the two marks on the dipstick. Do not overfill. If the level of oil raises above the second mark on the dipstick while the base is on a level surface, overheating may occur.

Replace the oil plug with a 6mm hex wrench. Do not overtighten. The

NOTE: With a new saw, change the oil following the first ten hours of use. This will prolong the life of the tool by removing the gear particles from the oil when the gears are breaking in.

BRUSH REPLACEMENT

See Figure 23.

The tool has externally accessible brush assemblies that should be periodically checked for wear.

Unplug the tool.

Remove the brush cap with a torx screwdriver. The brush assembly is spring loaded and will pop out when you remove the brush cap.

Remove the brush assembly (brush and spring).

Check for wear. If worn, always replace in pairs. Do not replace one side without replacing the other.

DIPSTICK

OIL PLUG

Fig. 22

|

| BRUSH | |

|

| ASSEMBLY | |

SCREWS | BRUSH |

| |

CAP | Fig. 23 | ||

| |||

|

|

23