R98LSE-ASME specifications

The Rinnai R98LSE-ASME is a high-efficiency tankless water heater that stands out for its powerful performance and advanced technology. This model is particularly designed to meet the demands of residential and commercial applications, delivering consistent hot water whenever it is needed. With a maximum flow rate of 9.8 gallons per minute, it is able to provide hot water for multiple outlets simultaneously, making it an excellent choice for busy households and commercial settings.One of the main features of the Rinnai R98LSE-ASME is its Energy Star rating, which signifies its exceptional energy efficiency. This rating not only helps reduce energy bills but also minimizes the environmental impact by consuming less gas over time. The unit is engineered with advanced condensing technology, which captures and reuses heat from exhaust gases, enhancing efficiency and cutting waste.

The R98LSE-ASME operates on a natural gas or propane option, allowing for flexibility depending on the available fuel supply. Its powerful burner system can quickly heat water to the desired temperature, ensuring that there's no waiting time for hot water. Additionally, the unit is designed with a temperature lock feature, which allows users to set and maintain their preferred water temperature easily, enhancing safety and convenience, especially in households with children.

Installation of the Rinnai R98LSE-ASME is straightforward, as it comes with a detailed manual and can be fitted into various environments, including closets and small spaces, due to its compact design. This versatility provides significant savings on space compared to traditional tank water heaters.

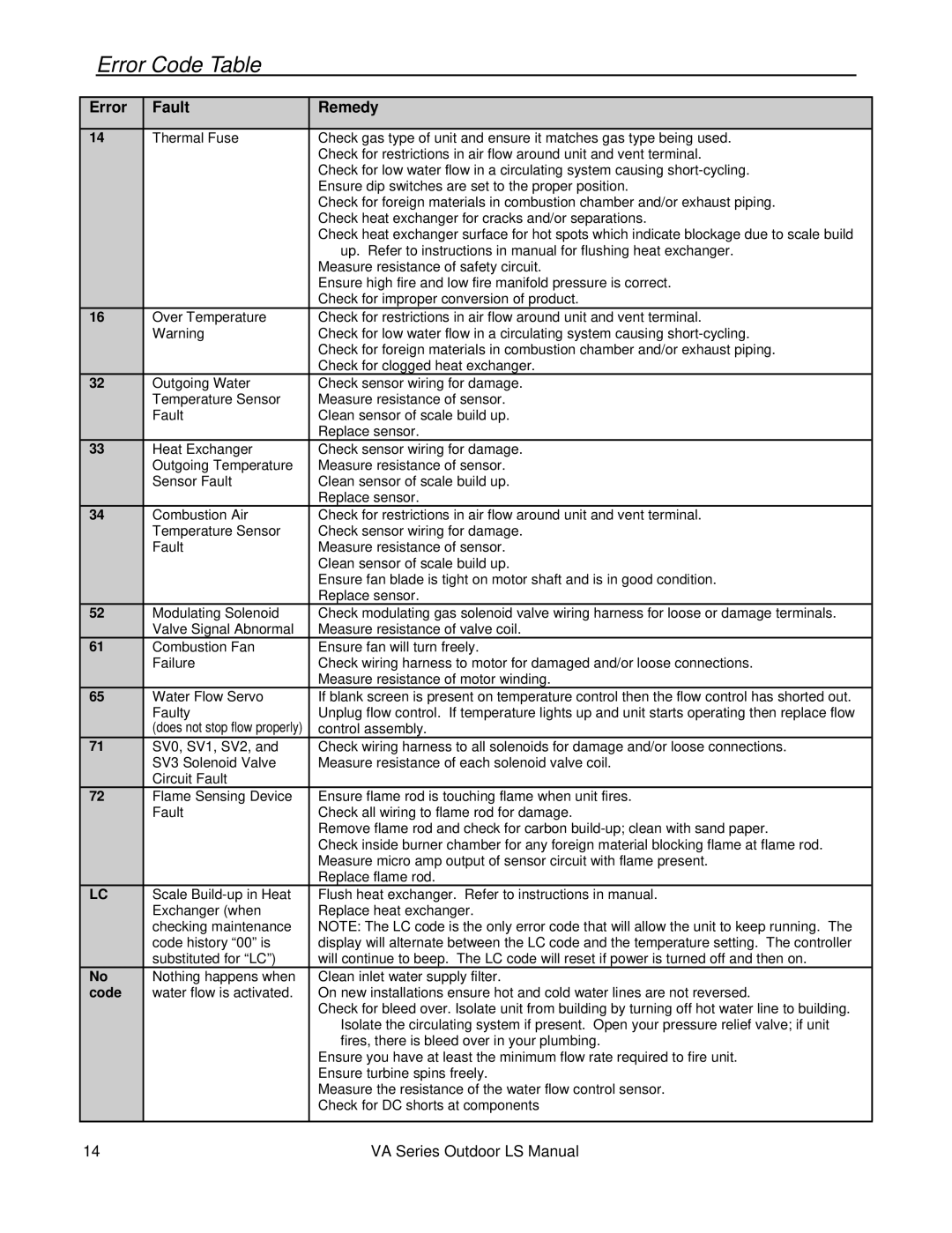

Safety is also a priority for Rinnai. The R98LSE-ASME includes a comprehensive set of safety features such as overheat protection, freeze protection, and built-in diagnostic codes for quick troubleshooting. This ensures reliable operation and peace of mind for users.

In summary, the Rinnai R98LSE-ASME is a high-performance tankless water heater that combines efficiency, reliability, and advanced technology. With features such as a high flow rate, Energy Star certification, and robust safety measures, it is well-suited for both residential and commercial applications, making it a worthy investment for anyone seeking a dependable hot water solution.