MAINTENANCE

-Cutter Drive Lever Pivot;

-Clutch/brake pedal pivot; See Fig.15

-Tie rod ball ends; Fig.11

-All connecting rod pivot points.

NOTE: All ball bearings are sealed and require no maintenance.

CUTTING UNIT:

Remove spark plug lead and disengage cutter drive before working on cutter unit, to prevent accidental starting of the engine.

Before using machine always inspect cutting unit to see that the cutting disc, blades and blade fixings are not worn or damaged.

Always check after striking a solid object. Do not operate machine when unusual vibration occurs.

Replace worn or damaged blades in sets to preserve balance. Remove any

CUTTING UNIT REMOVAL

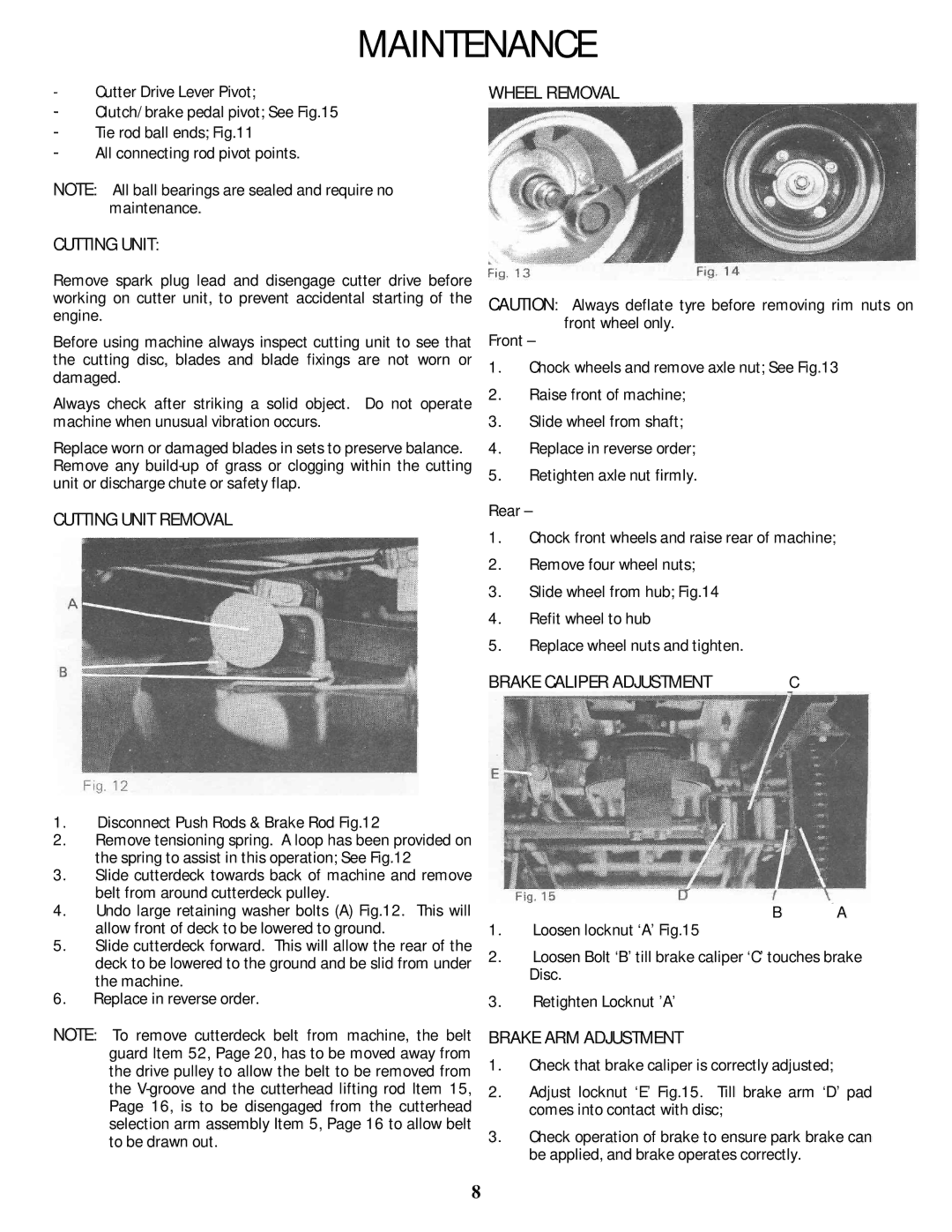

WHEEL REMOVAL

CAUTION: Always deflate tyre before removing rim nuts on front wheel only.

Front –

1.Chock wheels and remove axle nut; See Fig.13

2.Raise front of machine;

3.Slide wheel from shaft;

4.Replace in reverse order;

5.Retighten axle nut firmly.

Rear –

1.Chock front wheels and raise rear of machine;

2.Remove four wheel nuts;

3.Slide wheel from hub; Fig.14

4.Refit wheel to hub

5.Replace wheel nuts and tighten.

BRAKE CALIPER ADJUSTMENT | C |

1.Disconnect Push Rods & Brake Rod Fig.12

2.Remove tensioning spring. A loop has been provided on the spring to assist in this operation; See Fig.12

3.Slide cutterdeck towards back of machine and remove belt from around cutterdeck pulley.

4.Undo large retaining washer bolts (A) Fig.12. This will allow front of deck to be lowered to ground.

5.Slide cutterdeck forward. This will allow the rear of the deck to be lowered to the ground and be slid from under the machine.

6.Replace in reverse order.

NOTE: To remove cutterdeck belt from machine, the belt guard Item 52, Page 20, has to be moved away from the drive pulley to allow the belt to be removed from the

B A

1.Loosen locknut ‘A’ Fig.15

2.Loosen Bolt ‘B’ till brake caliper ‘C’ touches brake Disc.

3.Retighten Locknut ’A’

BRAKE ARM ADJUSTMENT

1.Check that brake caliper is correctly adjusted;

2.Adjust locknut ‘E’ Fig.15. Till brake arm ‘D’ pad comes into contact with disc;

3.Check operation of brake to ensure park brake can be applied, and brake operates correctly.

8