MAINTENANCE

COOLING SYSTEM

The Ranger has an air cooled 4 stroke engine. It must be cleaned frequently. Remove any

1.Cylinder;

2.Cylinder head cooling fins;

3.Cooling air intake screen and;

4.Carburetor governor levers and linkages.

This will ensure adequate cooling and correct engine speed.

THROTTLE CONTROL

Proper choke and stop switch operation is dependant on adjustment of remote controls –

1.Loosen outer cable clamp screw (D) on engine; See Fig.9.

2.Set throttle control to choke position;

3.Adjust outer cable under clamp plate so that choke is operated;

4.Tighten clamp plate screw and check –

a.Choke does not operate in fast position, and

b.Stop switch operates correctly.

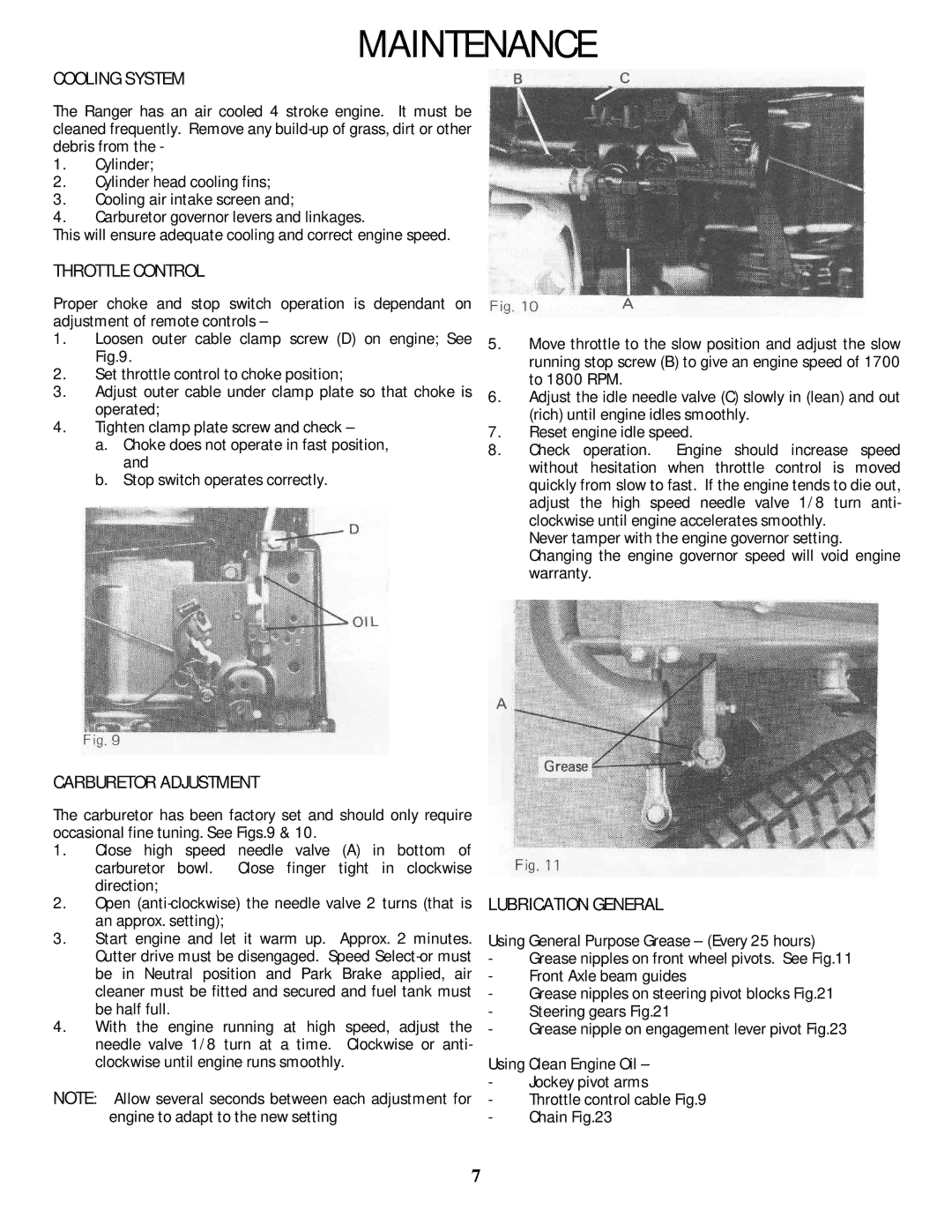

5.Move throttle to the slow position and adjust the slow running stop screw (B) to give an engine speed of 1700 to 1800 RPM.

6.Adjust the idle needle valve (C) slowly in (lean) and out (rich) until engine idles smoothly.

7.Reset engine idle speed.

8.Check operation. Engine should increase speed without hesitation when throttle control is moved quickly from slow to fast. If the engine tends to die out, adjust the high speed needle valve 1/8 turn anti- clockwise until engine accelerates smoothly.

Never tamper with the engine governor setting. Changing the engine governor speed will void engine warranty.

CARBURETOR ADJUSTMENT

The carburetor has been factory set and should only require occasional fine tuning. See Figs.9 & 10.

1.Close high speed needle valve (A) in bottom of carburetor bowl. Close finger tight in clockwise direction;

2. | Open |

| an approx. setting); |

3.Start engine and let it warm up. Approx. 2 minutes. Using General Purpose Grease – (Every 25 hours)

| Cutter drive must be disengaged. Speed | - | Grease nipples on front wheel pivots. See Fig.11 |

| be in Neutral position and Park Brake applied, air | - | Front Axle beam guides |

| cleaner must be fitted and secured and fuel tank must | - | Grease nipples on steering pivot blocks Fig.21 |

| be half full. | - | Steering gears Fig.21 |

4. | With the engine running at high speed, adjust the | - | Grease nipple on engagement lever pivot Fig.23 |

| needle valve 1/8 turn at a time. Clockwise or anti- |

|

|

| clockwise until engine runs smoothly. | Using Clean Engine Oil – | |

NOTE: Allow several seconds between each adjustment for | - | Jockey pivot arms | |

- | Throttle control cable Fig.9 | ||

| engine to adapt to the new setting | - | Chain Fig.23 |

7