MAINTENANCE

AUTO DRIVE

The

If during operation it is found that the relationship between forward and reverse has become unbalanced adjust as follows:-

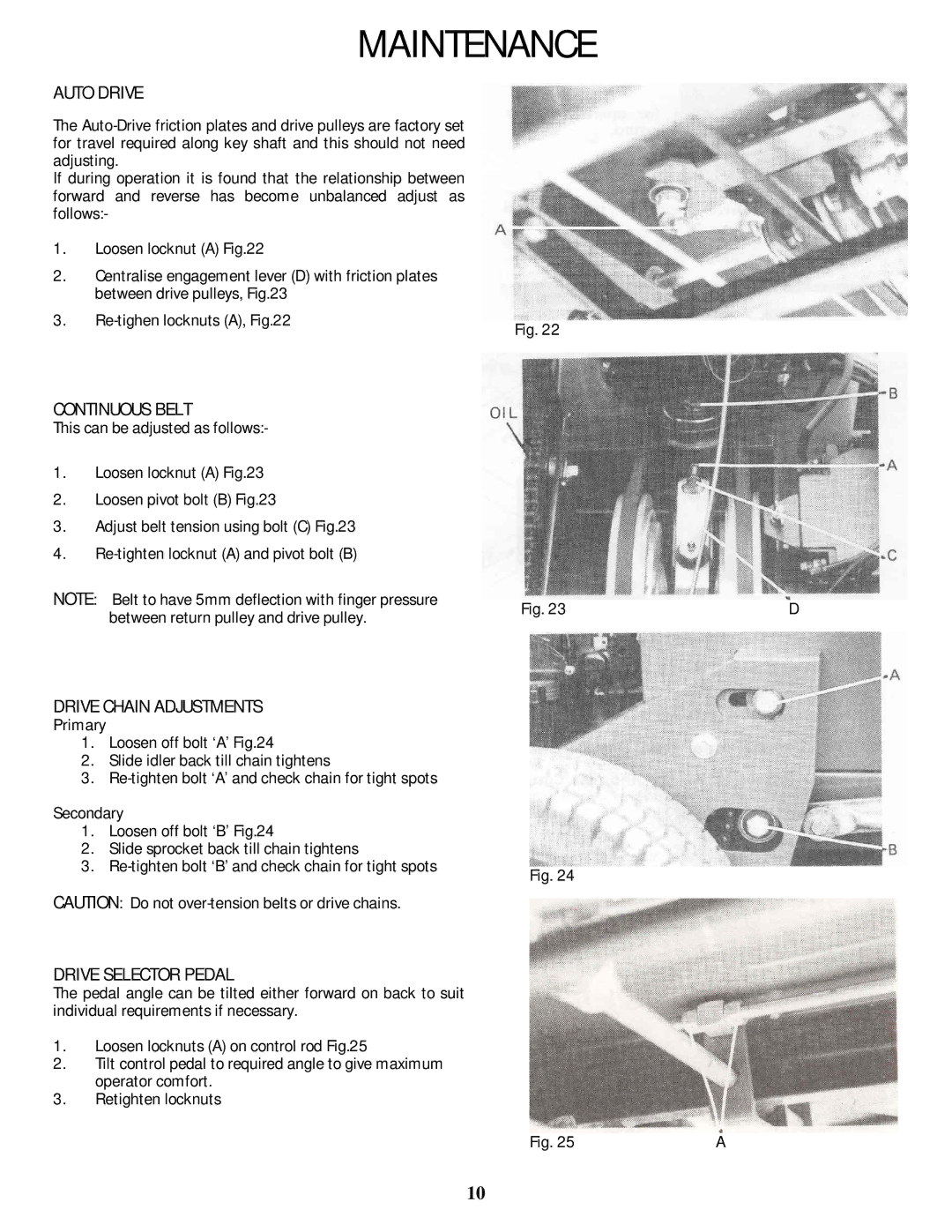

1.Loosen locknut (A) Fig.22

2.Centralise engagement lever (D) with friction plates between drive pulleys, Fig.23

3. | Fig. 22 | |

|

|

CONTINUOUS BELT

This can be adjusted as follows:-

1.Loosen locknut (A) Fig.23

2.Loosen pivot bolt (B) Fig.23

3.Adjust belt tension using bolt (C) Fig.23

4.

NOTE: Belt to have 5mm deflection with finger pressure between return pulley and drive pulley.

DRIVE CHAIN ADJUSTMENTS

Primary

1.Loosen off bolt ‘A’ Fig.24

2.Slide idler back till chain tightens

3.

Secondary

1.Loosen off bolt ‘B’ Fig.24

2.Slide sprocket back till chain tightens

3.

CAUTION: Do not

DRIVE SELECTOR PEDAL

The pedal angle can be tilted either forward on back to suit individual requirements if necessary.

1.Loosen locknuts (A) on control rod Fig.25

2.Tilt control pedal to required angle to give maximum operator comfort.

3.Retighten locknuts

Fig. 23 | D |

Fig. 24

Fig. 25 | A |

10