ADJUSTMENTS

DEPTH STOP

The depth stop limits the wheel's downward travel. It allows the wheel to go below the machine base enough to maintain full cutting capacities.

The adjustable depth stop is a nylok bolt threaded into the base of the machine at the rear. To adjust the depth stop use an 8 mm wrench to raise or lower the depth stop bolt.

The depth stop is factory set to provide maximum cutting capacity for the 14 in. (356 mm) abrasive wheel provided with your

When the diameter of the wheel has been reduced due to wear, it may be necessary to adjust the depth stop to provide maximum cutting capacity. When a new abrasive wheel is installed, it is necessary to check the clearance of the wheel to the machine base support.

DEPTH STOP ADJUSTMENTS

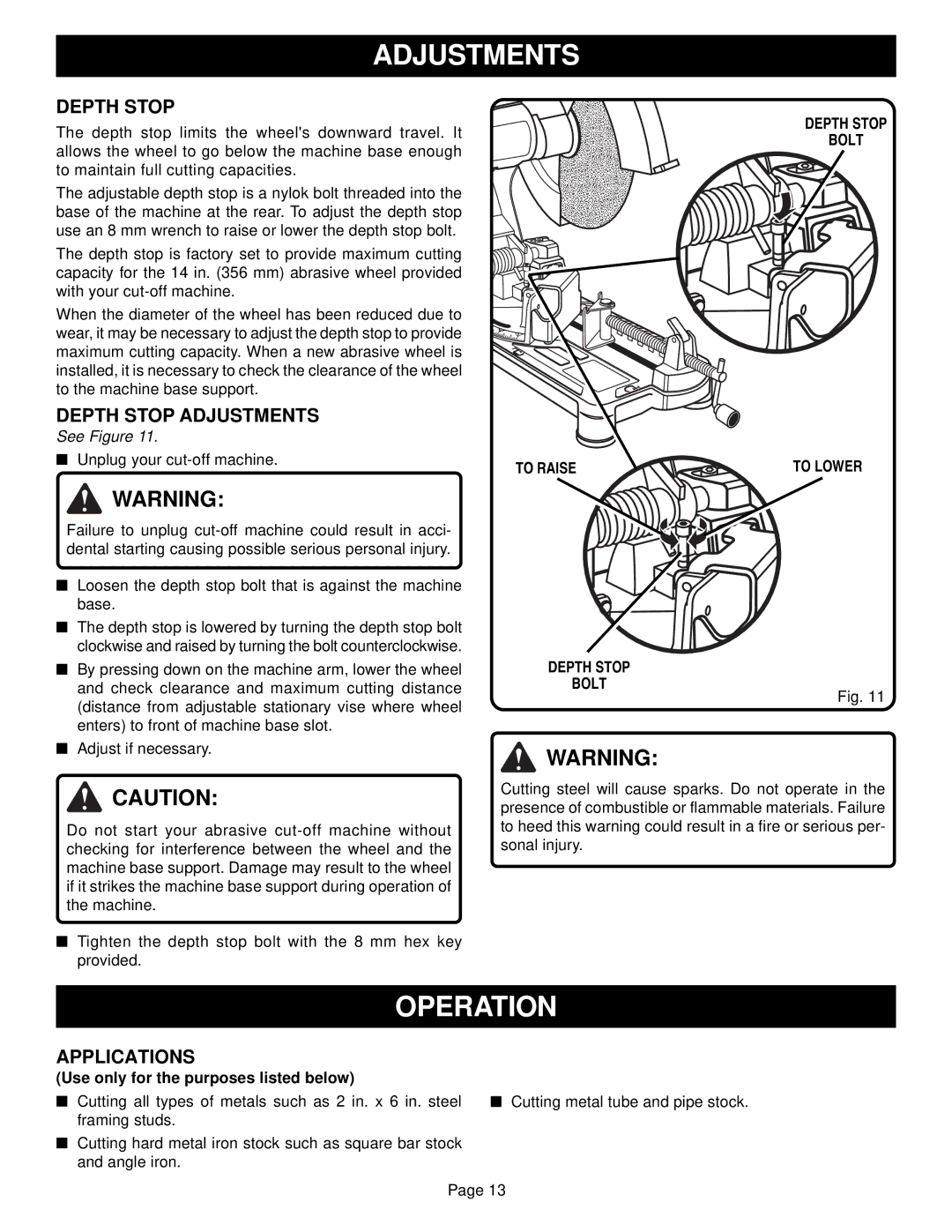

See Figure 11.

■Unplug your

WARNING:

Failure to unplug

■Loosen the depth stop bolt that is against the machine base.

■The depth stop is lowered by turning the depth stop bolt clockwise and raised by turning the bolt counterclockwise.

■By pressing down on the machine arm, lower the wheel and check clearance and maximum cutting distance (distance from adjustable stationary vise where wheel enters) to front of machine base slot.

■Adjust if necessary.

CAUTION:

Do not start your abrasive

■Tighten the depth stop bolt with the 8 mm hex key provided.

DEPTH STOP

BOLT

TO RAISE | TO LOWER |

DEPTH STOP

BOLT

Fig. 11

WARNING:

Cutting steel will cause sparks. Do not operate in the presence of combustible or flammable materials. Failure to heed this warning could result in a fire or serious per- sonal injury.

OPERATION

APPLICATIONS

(Use only for the purposes listed below)

■ Cutting all types of metals such as 2 in. x 6 in. steel ■ Cutting metal tube and pipe stock. framing studs.

■Cutting hard metal iron stock such as square bar stock and angle iron.

Page 13