FEATURES

KNOW YOUR DRILL PRESS | FEED HANDLES |

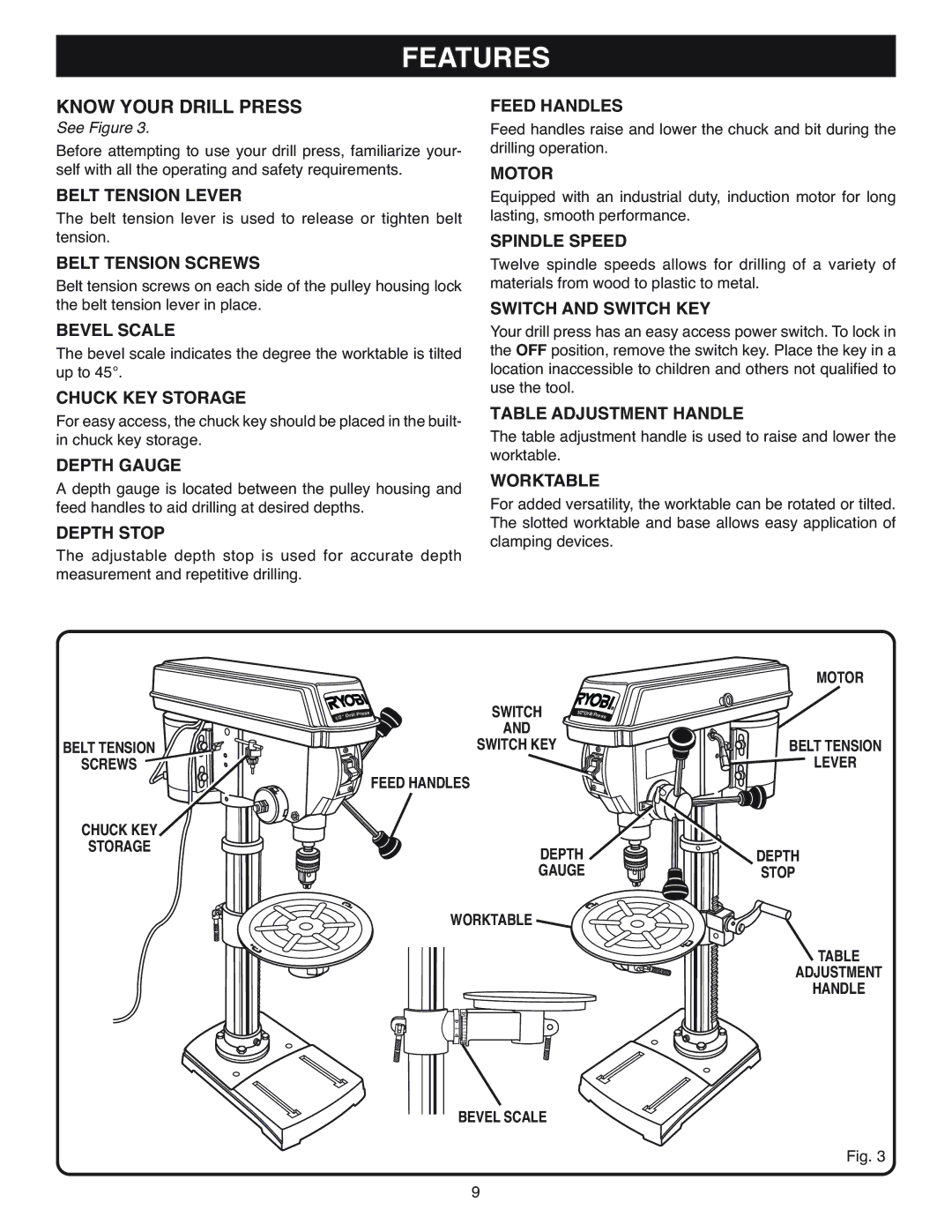

See Figure 3.

Before attempting to use your drill press, familiarize your- self with all the operating and safety requirements.

BELT TENSION LEVER

The belt tension lever is used to release or tighten belt tension.

BELT TENSION SCREWS

Belt tension screws on each side of the pulley housing lock the belt tension lever in place.

BEVEL SCALE

The bevel scale indicates the degree the worktable is tilted up to 45°.

CHUCK KEY STORAGE

For easy access, the chuck key should be placed in the built- in chuck key storage.

DEPTH GAUGE

A depth gauge is located between the pulley housing and feed handles to aid drilling at desired depths.

DEPTH STOP

The adjustable depth stop is used for accurate depth measurement and repetitive drilling.

Feed handles raise and lower the chuck and bit during the drilling operation.

MOTOR

Equipped with an industrial duty, induction motor for long lasting, smooth performance.

SPINDLE SPEED

Twelve spindle speeds allows for drilling of a variety of materials from wood to plastic to metal.

SWITCH AND SWITCH KEY

Your drill press has an easy access power switch. To lock in the OFF position, remove the switch key. Place the key in a location inaccessible to children and others not qualified to use the tool.

TABLE ADJUSTMENT HANDLE

The table adjustment handle is used to raise and lower the worktable.

WORKTABLE

For added versatility, the worktable can be rotated or tilted. The slotted worktable and base allows easy application of clamping devices.

MOTOR

BELT TENSION

SCREWS

| l Press |

” Dril | |

1/2 |

|

FEED HANDLES

SWITCH

AND

SWITCH KEY

1 | 2 | Drill Pr |

|

| ess |

|

| ON |

BELT TENSION

![]() LEVER

LEVER

CHUCK KEY |

|

|

STORAGE | DEPTH | DEPTH |

| ||

| GAUGE | STOP |

WORKTABLE

TABLE

ADJUSTMENT

HANDLE

| 40 30 |

| 20 |

| 10 |

0 | 0 |

| 10 |

| 20 |

| 30 |

| 40 |

BEVEL SCALE

Fig. 3

9