MAINTENANCE

■Reassemble using new brush assembly. Make sure curvature of brush matches curvature of motor and that brush moves freely in brush tube. Use the blunt end of something thin (eraser end of pencil, etc.) to push the brush into the tube until it stays.

■Make sure brush cap is oriented correctly (straight) and replace.

■Tighten brush cap using a hand powered screwdriver only. Do not overtighten.

■Repeat for other brush.

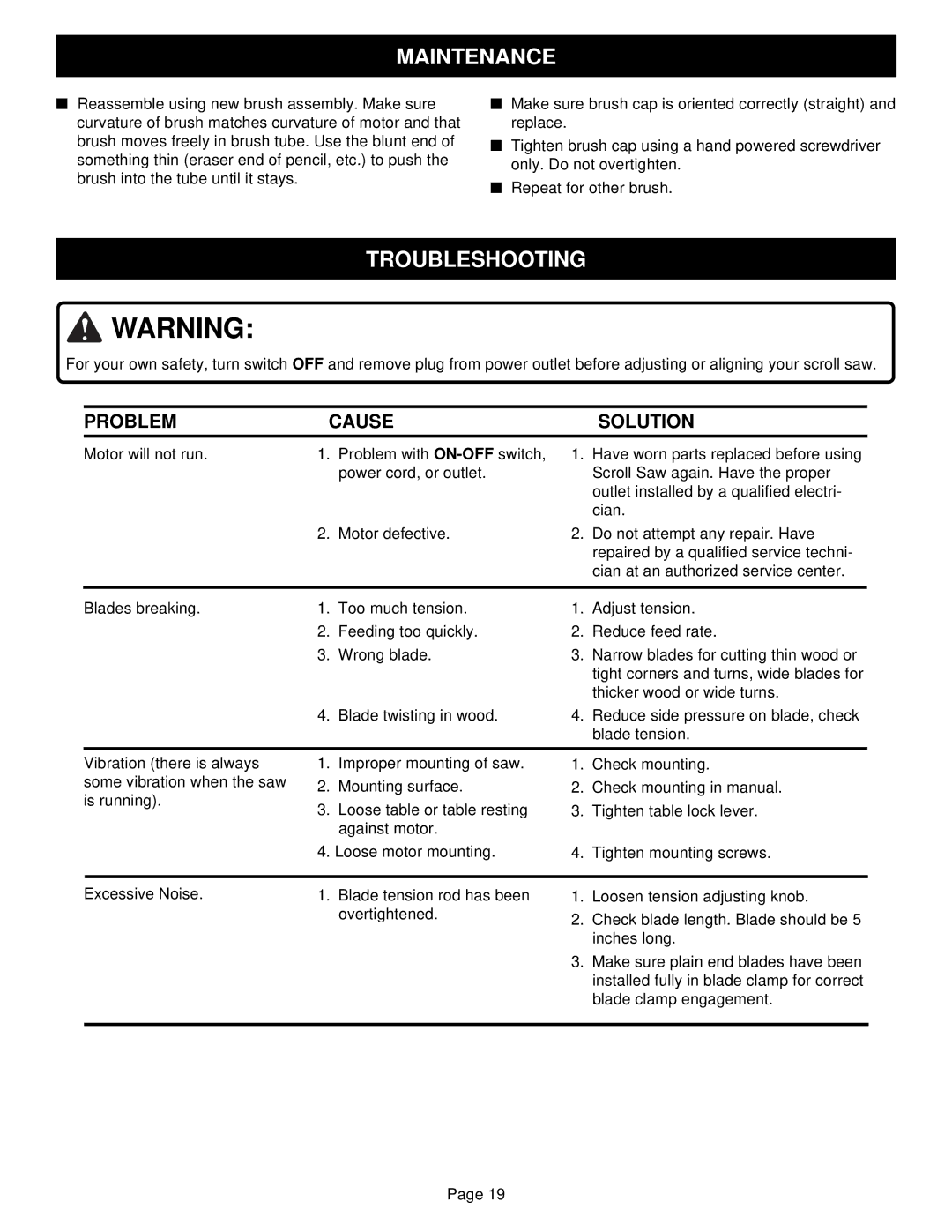

TROUBLESHOOTING

![]() WARNING:

WARNING:

For your own safety, turn switch OFF and remove plug from power outlet before adjusting or aligning your scroll saw.

PROBLEM | CAUSE |

| SOLUTION | |

Motor will not run. | 1. Problem with | 1. | Have worn parts replaced before using | |

|

| power cord, or outlet. |

| Scroll Saw again. Have the proper |

|

|

|

| outlet installed by a qualified electri- |

|

|

|

| cian. |

| 2. | Motor defective. | 2. | Do not attempt any repair. Have |

|

|

|

| repaired by a qualified service techni- |

|

|

|

| cian at an authorized service center. |

|

|

|

|

|

Blades breaking. | 1. | Too much tension. | 1. | Adjust tension. |

| 2. | Feeding too quickly. | 2. | Reduce feed rate. |

| 3. | Wrong blade. | 3. | Narrow blades for cutting thin wood or |

|

|

|

| tight corners and turns, wide blades for |

|

|

|

| thicker wood or wide turns. |

4. Blade twisting in wood.

4.Reduce side pressure on blade, check blade tension.

Vibration (there is always some vibration when the saw is running).

1.Improper mounting of saw.

2.Mounting surface.

3.Loose table or table resting against motor.

1.Check mounting.

2.Check mounting in manual.

3.Tighten table lock lever.

4. Loose motor mounting. | 4. Tighten mounting screws. |

Excessive Noise. | 1. Blade tension rod has been |

| overtightened. |

1.Loosen tension adjusting knob.

2.Check blade length. Blade should be 5 inches long.

3.Make sure plain end blades have been installed fully in blade clamp for correct blade clamp engagement.

Page 19