CG408TT, CG412TT, CG408DT, CG412DT specifications

The SATO CG412TT, CG408TT, CG412DT, and CG408DT are advanced thermal transfer printers designed for high-performance label printing in various industries, including retail, manufacturing, and logistics. These models are well-known for their reliability, flexibility, and ease of use, making them suitable for a wide range of applications.One of the standout features of the CG412TT and CG408TT is their robust print resolution. With an impressive print resolution of 300 dpi, these printers deliver sharp and clear images, ensuring that barcodes and text are easily readable. This high-resolution capability is critical for industries that require precise labeling, such as pharmaceuticals and food packaging.

The CG412DT and CG408DT models, on the other hand, focus on direct thermal printing, eliminating the need for ribbons and providing a cost-effective solution for short-run applications. This technology is ideal for transient labels where longevity is not a primary concern. Both direct thermal models still offer high-speed printing, ensuring efficiency in busy environments.

One of the key characteristics of these SATO printers is their versatility. They support a wide range of media types, including various label sizes, colors, and materials. This adaptability allows businesses to customize their labeling needs without investing in multiple printers.

Another important feature is the upgraded communication options. The CG412TT, CG408TT, CG412DT, and CG408DT printers come equipped with multiple connectivity options, including USB, Ethernet, and optional wireless connectivity. This enhanced connectivity facilitates seamless integration into existing systems, providing flexibility in deployment.

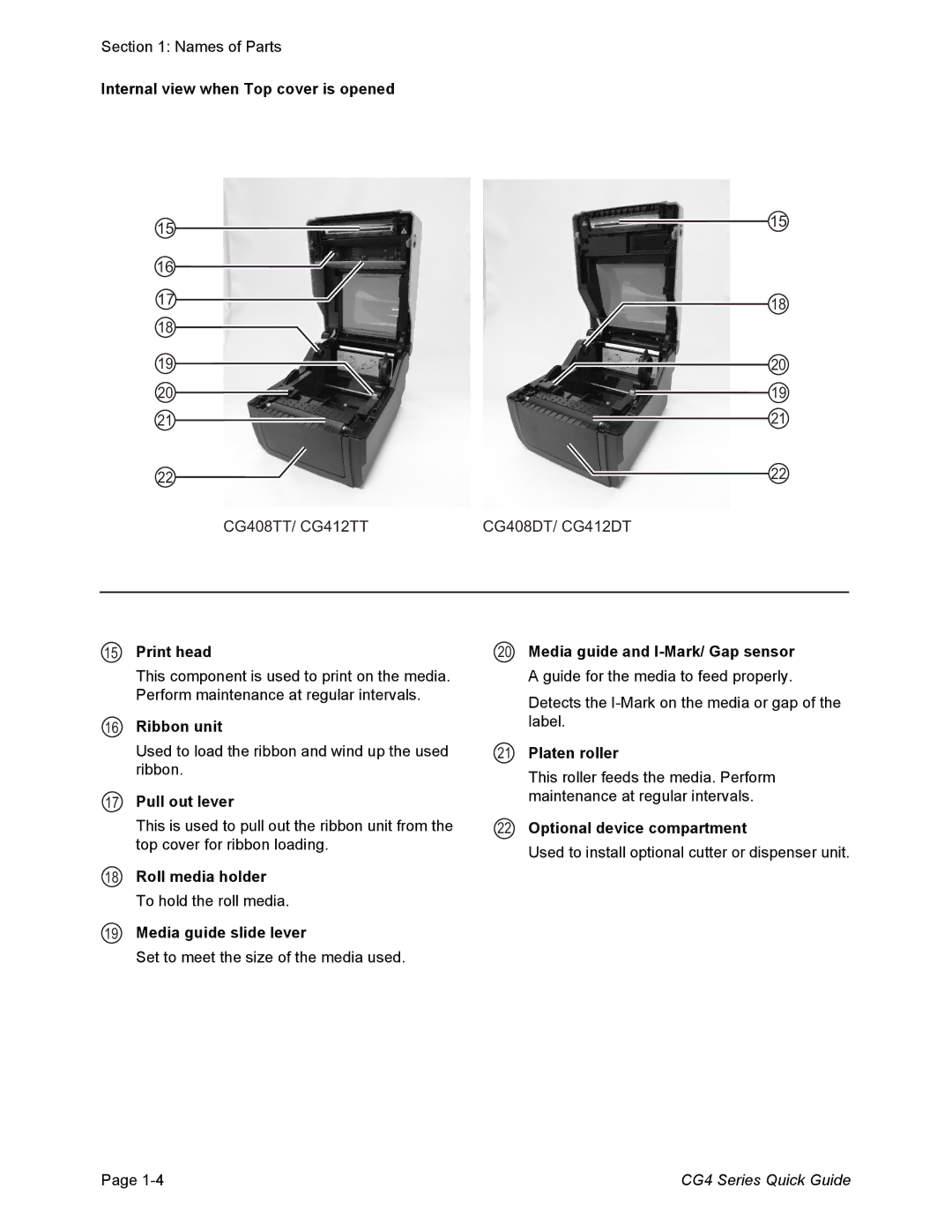

User-friendliness is also a significant consideration in these models. They feature an intuitive LCD display that simplifies setup and operation, allowing users to easily navigate through settings and adjustments. Maintenance is straightforward, with easy ribbon and media loading, minimizing downtime and optimizing productivity.

In summary, the SATO CG412TT, CG408TT, CG412DT, and CG408DT printers are excellent choices for businesses seeking reliable, high-quality printing solutions. With their diverse features, advanced technologies, and robust characteristics, they cater to a variety of labeling needs while ensuring efficiency and effectiveness in operations. Whether it is for thermal transfer or direct thermal applications, these printers stand out in delivering performance and quality.