Section 6

To adjust the

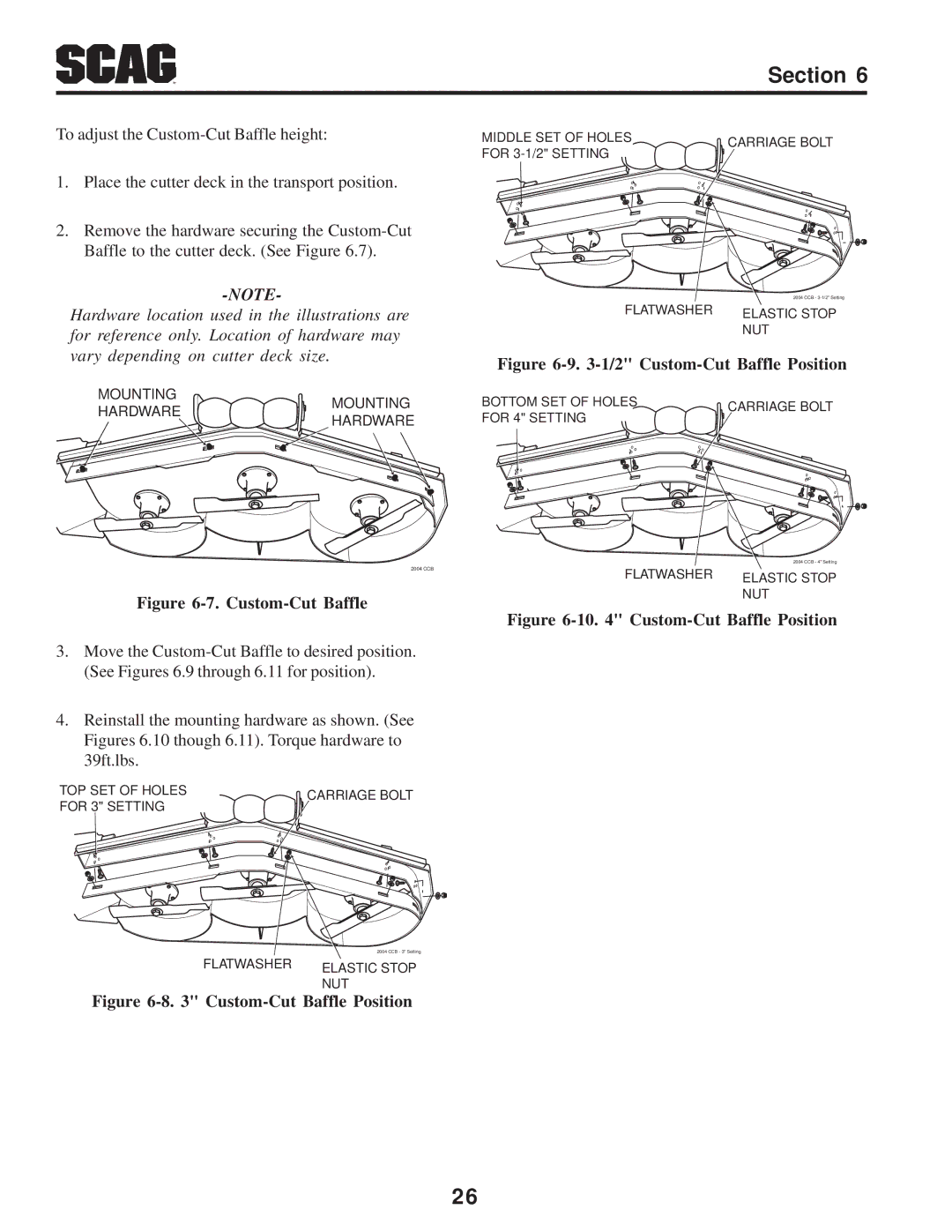

1.Place the cutter deck in the transport position.

2.Remove the hardware securing the

Hardware location used in the illustrations are for reference only. Location of hardware may vary depending on cutter deck size.

MOUNTING | MOUNTING | |

HARDWARE | ||

HARDWARE | ||

|

2004 CCB

Figure 6-7. Custom-Cut Baffle

MIDDLE SET OF HOLES | CARRIAGE BOLT | |

FOR | ||

|

|

| 2004 CCB - | |

FLATWASHER | ELASTIC STOP | ||

|

| ||

|

| NUT | |

Figure | |||

|

|

| |

BOTTOM SET OF HOLES |

|

|

|

CARRIAGE BOLT |

| ||

FOR 4" SETTING |

|

| |

|

|

| |

| 2004 CCB - 4" Setting |

FLATWASHER | ELASTIC STOP |

| |

| NUT |

Figure 6-10. 4" Custom-Cut Baffle Position

3.Move the

4.Reinstall the mounting hardware as shown. (See Figures 6.10 though 6.11). Torque hardware to 39ft.lbs.

TOP SET OF HOLES | CARRIAGE BOLT | |

FOR 3" SETTING | ||

|

| 2004 CCB - 3" Setting |

FLATWASHER | ELASTIC STOP |

| |

| NUT |

Figure 6-8. 3" Custom-Cut Baffle Position

26