STHM specifications

Scag Power Equipment has long been known for its high-quality, reliable machinery, and their STHM line of products showcases some of the best features and technologies available in the landscaping equipment world. The STHM stands for Scag Turf-Hawk Mower, which combines efficiency and performance for both professional landscapers and homeowners seeking a durable mowing solution.One of the standout features of the STHM is its robust engine options. With powerful engines from trusted brands, users can enjoy increased cutting performance and fuel efficiency. This ensures that the mower is not only capable of handling tough jobs but can also operate for extended periods without frequent refueling. The machinery is designed with professional landscapers in mind, providing them with the horsepower needed to tackle larger properties and more demanding conditions.

Another notable aspect of the STHM is its cutting deck design. Scag Power Equipment meticulously engineers their cutting decks for optimal airflow and discharge, creating a clean and even cut every time. The deck is often made of heavy-duty steel, ensuring durability and resistance to wear and tear. With adjustable deck heights, users can easily customize their mowing performance to suit different grass types and terrain conditions.

User comfort and control are also prioritized in the design of the STHM. The ergonomic controls and comfortable seating allow operators to work longer with less fatigue. Features like vibration dampening and adjustable armrests contribute to a smoother ride, making the entire mowing experience more pleasant.

In terms of technology, the STHM is equipped with advanced features such as precision steering and responsive handling. The zero-turn capability empowers users to maneuver around obstacles with ease, increasing efficiency and reducing mowing time. Additionally, some models include digital displays that provide real-time information about engine performance, fuel levels, and maintenance reminders, ensuring that the equipment runs optimally.

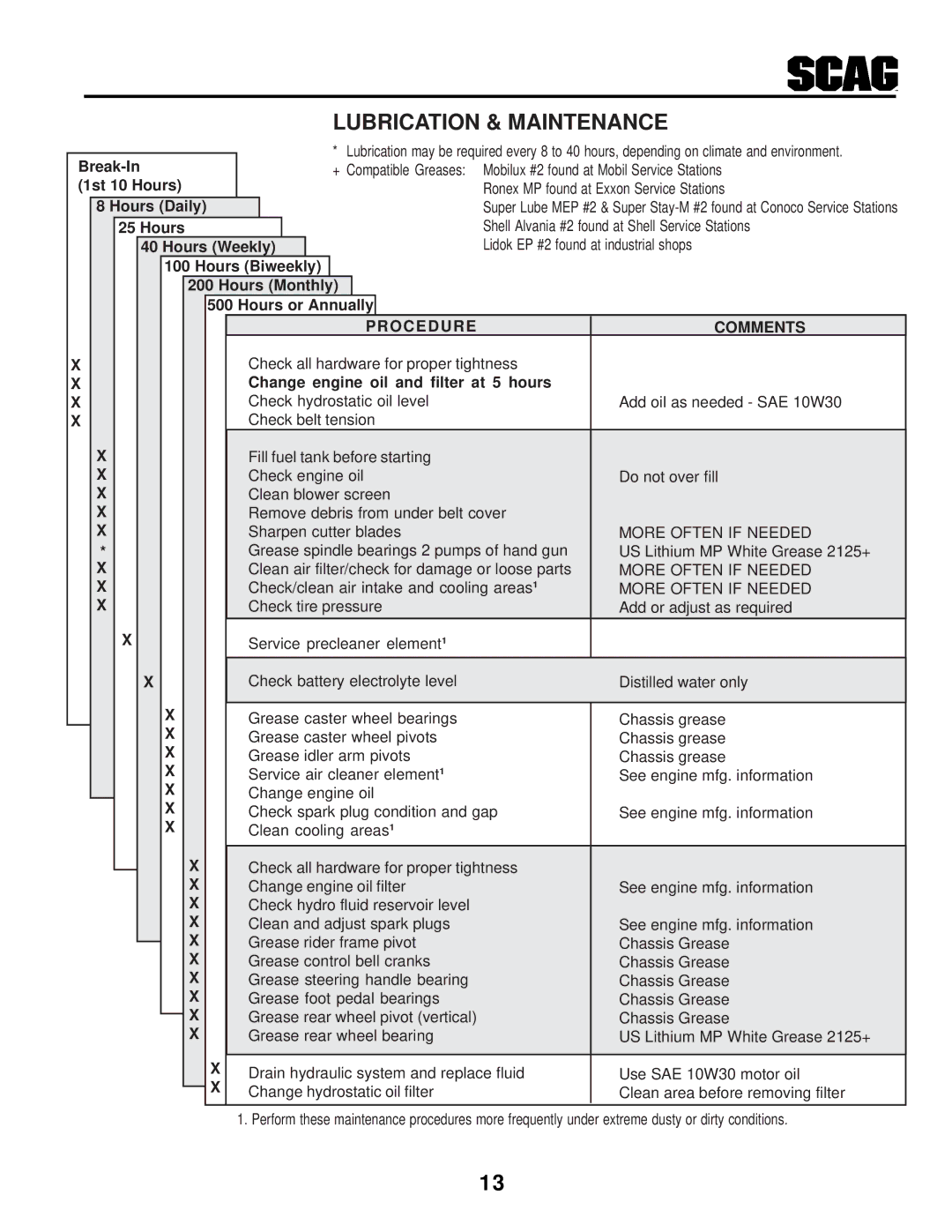

Maintenance is a breeze with the STHM thanks to features like easy-access service points, making routine upkeep simple and efficient. Users can quickly check oil levels, replace filters, and maintain blades, which contributes to the longevity and performance of the mower.

Overall, the Scag Power Equipment STHM line represents a commitment to quality and innovation, delivering powerful performance, user-friendly design, and advanced technology that appeals to both professionals and enthusiasts alike. Whether for residential or commercial use, the STHM offers everything needed for a precise and efficient mowing experience.