OPERATOR’S Manual

With a serial number D8100001 to D8199999

With a serial number D7700001 to D7799999

With a serial number D7800001 to D7899999

With a serial number D9900001 to D9999999

Table of Contents

Cutter Deck Adjustments Custom-Cut Baffle Adjustment

Parking Brake Adjustment

Throttle Control And Choke Adjustments

Maintenance Chart Recommended Service Intervals

Inside Back Cover

Direction Reference

Introduction

Servicing The Engine And Drive Train Components

Symbols

STT Models

Signal Word

Signal Words

This symbol means Attention! Become Alert! Your

Before Operation Considerations

Operation Considerations

Section

Roll-Over Protection System

Foldable Roll-over protection system if equipped

Foldable Roll-Over Protection System

Maintenance Considerations & Storage

Safety And Instructional Decals Install Belt COvER Before

Engine

Electrical

Power Head

Cutter Deck

Hydraulic System

Weights And Dimensions 52V 61V 72A / 72VS

Productivity 52V 61V 72A / 72VS

Operating Instructions

Controls And Instrument Identification

Safety Interlock System

Dump Valve Control

Ground Travel And Steering

Initial Run-In Procedures

Starting The Engine

Forward Travel

Engaging The Deck Drive Cutter Blades

Reverse Travel

After Operation

Hillside Operation

Parking The Mower

Removing Clogged Material

Moving Mower With Engine Stopped

Adjusting Cutting Height

Recommendations For Mowing

Adjusting The Steering Levers

Adjusting The Height Adjust Pedal

Towing Optional Hitch Accessory

Condition Cause Cure

Cut, or Rough Contour

E v e n C u t o n F l at

Ground Wavy High-Low Appearance, Scalloped

Sloping Ridge Across

Step Cut Ridge in Center

Scalping Blades Hitting

Dirt or CuttingVery Close To the Ground

Cutting path

Adjustments

Parking Brake Adjustment

Travel Adjustments

Neutral Adjustment

Belt Adjustment

Throttle Control And Choke Adjustments

Tracking Adjustment

Cutter Deck Level

Cutter Deck Adjustments

Belt Alignment

Cutter Deck Pitch

Position Custom-Cut Baffle Adjustment eARLY mODELS

Custom-Cut Baffle Adjustment

Cutter Deck Height

Position Custom-Cut Baffle Adjustment cURRENT pRODUCTION

Position Custom-Cut Baffle Adjustment

Maintenance Chart Recommended Service Intervals

Procedure Comments Break-In 100 200 500 First

Maintenance Chart Recommended Service Intervals Contd

Lubrication

Lubrication Fitting Points

Checking Hydraulic Oil Level

Changing Hydraulic Oil

Engine Oil

Engine Fuel System

Cleaning and/or Replacing Air Cleaner Element

Engine Air Cleaner

Replacing In-Line Fuel Filter Elements

Charging the Battery

Battery

Jump Starting

Cutter Blades

Blade Replacement

Drive Belts

Blade Inspection

Cutter Deck Gearbox

Tires

Checking Lubricant Level

Changing Lubricant

Cleaning the Radiator Debris Screen

Cooling System

Liquid-Cooled Machines Only

Body, Deck, And Upholstery

Checking The Fan Belt Tension Liquid- Cooled Engines Only

Illustrated Parts List

Scag Approved Attachments And Accessories

22A

52V Cutter Deck

61V & 72VS Cutter Decks

04001-136

72A Cutter Deck

461865 Cutter Deck, 72 Advantage w/Decals

Cutter Deck Controls

Slide Weldment, Height Adjustment

Sheet Metal Components

9278

STT 2007 Rops

Description

Section STT ROLL-OVER Protection System with Suspension Seat

Section STT ROLL-OVER Protection System with Suspension Seat

Deck Drive Components

Bolt, Hex Head 3/8-16 x

Engine and Attaching Parts Kohler

Available through the individual engine manufacturer

Engine & Attaching Parts 27HP, 29DFI Kawasaki

Engine & Attaching Parts 27HP, 29DFI Kawasaki

Engine & Attaching Parts 35HP Briggs & Stratton

Engine & Attaching Parts 35HP Briggs & Stratton

Brake and Steering Components

Bolt, Carriage 5/16-18 x

Fuel and Hydraulic System

Inch

Fuel and Hydraulic System 29DFI Kawasaki

481164 Cap, Hydraulic Tank 481507 Insert, Filler Neck

BDP-16A Hydraulic Pump Assembly

BDP-16A Hydraulic Pump Assembly

Port a Side

Description

Electrical System Kohler

Ammeter

Electrical System 27HP KAWASAKI, 35BV Briggs & Stratton

Water Temp. Gauge

Electrical System 29DFI Kawasaki

Water Temp. Gauge STT KA Only

Heavy-Duty

STT Decals Page2

STT Electrical Schematic Kohler

STT Electrical Schematic 27HP Kawasaki

Electrical Schematic 29DFI Kawasaki

Electrical Schematic Briggs & Stratton 35BV

Section

Limited Warranty Commercial Equipment

Garantía Limitada Equipo Comercial

Sección

Solamente

Corte DE Plataforma

LA DE Cambios DE Caja

Refrigeración DE Sistema

Llantas

Cuchillas las de Afilado .B

Corte DE Cuchillas

Transmisión DE Correas

Batería

Batería DE Electrolito Para Auxilios Primeros

Motor

DEL Combustible DE Sistema

Hidráulico

Hidráulico Sistema

Hidráulico aceite de Cambio .B

Conexión de puntos de Lubricación 1-7 Figura

36 Página 1,-7 Figura LA VEA

Grasa DE Conexión DE Lubricación DE Tabla Lubricación

Recomendados Servicio DE Intervalos Mantenimiento DE Tabla

Refrigerante del nivel el Verifique

De personalizado

Personalizado corte de deflector del Ajuste

Corte de plataforma la de Altura

Corte

DE Plataforma LA DE Ajustes

Correa LA DE Ajuste

Correa LA DE Alineación

Estrangulación Y Aceleración DE Controles LOS DE Austes

Desplazamiento DE Ajustes

Izquierda mano a Derecha mano a

Estacionamiento DE Freno DEL Ajuste

Scag de autorizado

Solución Causa Condición

Lo a inclinadas Salientes

Corte de

Trayectoria la de ancho

Irregular

Cortar sin césped

Corte

De trayectorias entre

De Franjas Vetas

Sección

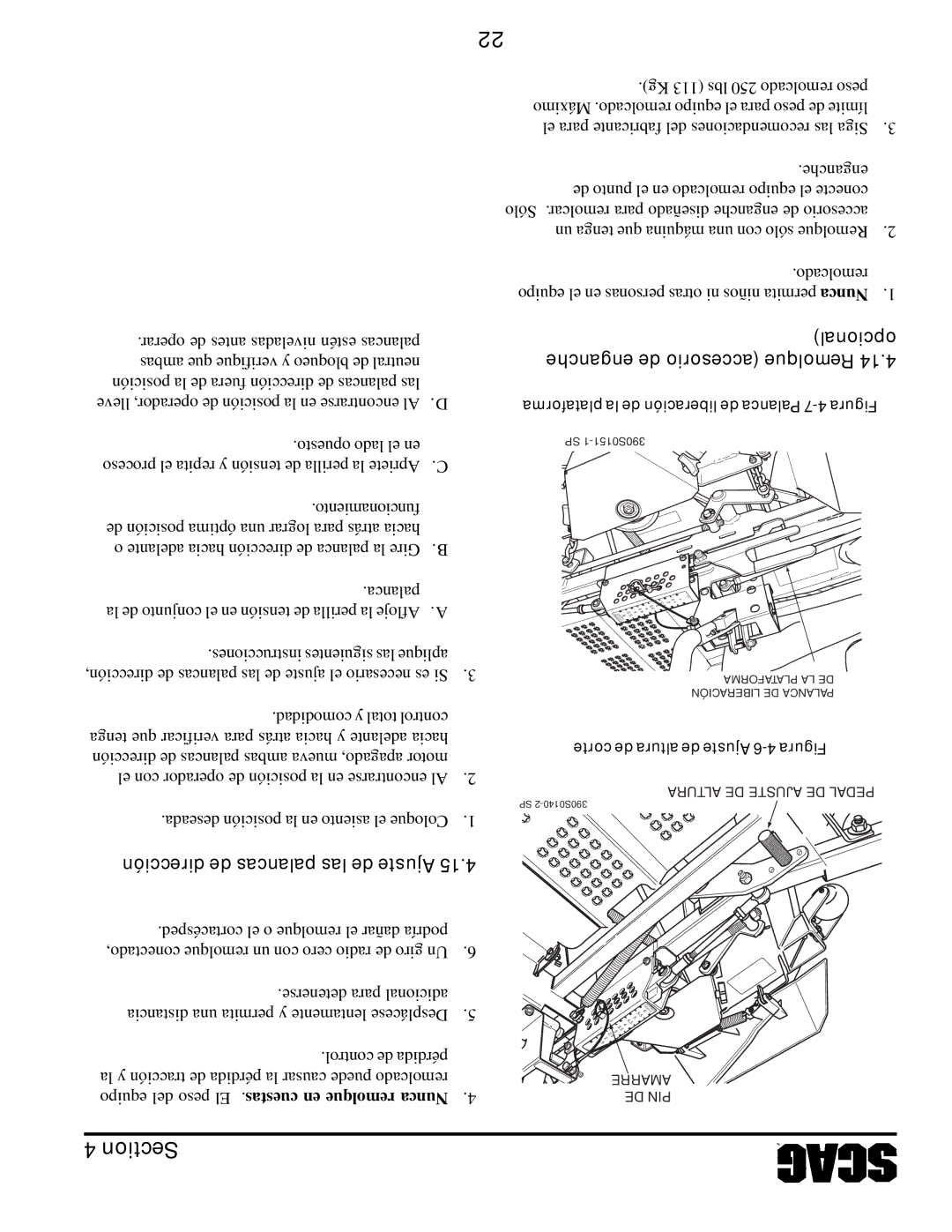

Altura la de ajuste de pedal del Ubicaciones 9-4 Figura

Dirección de palancas las de Ajuste

Opcional enganche de accesorio Remolque

Advertencia

En palancas las ponga corte, de cuchillas las a

Ocurrido ha Si MOTIVO! Ningún POR Descarga

Rellenar y combustible

Cuesta UNA EN Operación

Reversa en Desplazamiento

Adelante hacia Desplazamiento

Una causar o explosivo potencialmente ser puede

Personales lesiones y/o motor al daños causar

De uso El .ARRANQUE DE Líquidos USE no

Figura estacionamiento de freno del Control

Instrumentos e controles los todos de propósito

Horario control de Instrumentos e Controles 1-4 Figura

Cortacésped este operar de antes

El y ubicación la Aprenda .manual este leído haya

Productividad

Continuación 3TRACTOR.3

3TRACTOR.3

Reversa Adelante

Seguridad DE Y Instructivas Calcomanías

Dé entrenamiento sin personalNUNCAque permita.8

Almacenamiento Y Mantenimiento DE Consideraciones

Rops del Bisagra 2-2 Figura

Precaución

Vuelco Contra Protección DE Sistema

Operación DE Consideraciones

Osha POR Aprobadas Operaciones

Sección

Operación LA a Operar DE Antes

Señalización DE Palabras

Lento Rápido

Símbolos

Instrucciones DE Referencia

Introducción

Continuación Contenido DE Tabla

Contenido DE Tabla

61V-SMT

72A-SMST

BV BVAC, 61V-SMT

52V-SMT

Manual

![]() AMARRE equipo del peso ElDE .PIN

AMARRE equipo del peso ElDE .PIN