Causes of high voltage drops can be from LOOSE OR COR- RODED CONNECTIONS at the output terminal of the alternator, the car’s ammeter, battery terminal connection on the starter so- lenoid, battery cable connections, faulty wiring from alternator to regulator, to ammeter, to starter solenoid, or between the alter- nator and the engine.

Hook up the Analyzer as for all of the tests, with the Battery Clamps on the battery terminals.

1.Set Volts Selector to external ±199.9V.

2.Run engine at about 1500 RPM

3.Turn blower motor and headlights to high.

4.Measure Insulated Circuit voltage drop by connecting voltmeter from battery POS post to the alternator output terminal. See Figure 7. Over ±0.5V shows bad connections.

ALTERNATOR

OUTPUT

POS

BATTERY

Figure 7

5.Measure Ground Circuit voltage drop by connecting voltmeter from battery NEG post to the alternator case. Over ±0.2V shows bad connections. See Figure 8.

ALTERNAOR

CASE

| NEG |

|

| BATTERY | SOLENOID |

|

| |

CHASSIS |

| RELAY |

|

|

Figure 8

6.Test conclusion : If the circuit resistance voltage drops are high, repair the bad connections.

Typical ratings for total circuit voltage drops at full output current:

General Motor | 0.7V |

|

Chrysle | 0.9V |

|

Ford Motors | 0.4V with lamp | |

Ford Motors | 0.8V | w/ammeter |

If the voltage drops are not the problem, go to the Regulator Ground Test.

REGULATOR GROUND TEST

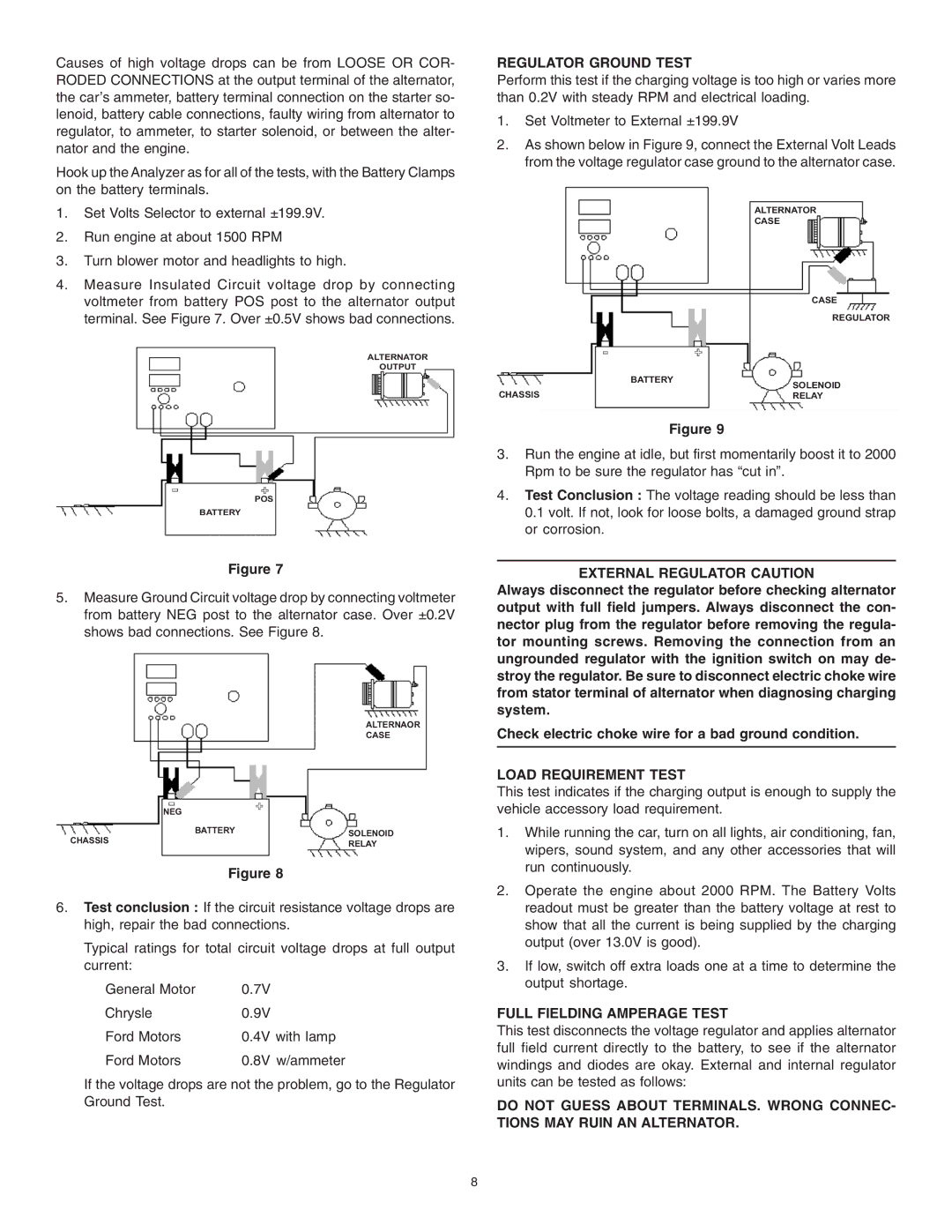

Perform this test if the charging voltage is too high or varies more than 0.2V with steady RPM and electrical loading.

1.Set Voltmeter to External ±199.9V

2.As shown below in Figure 9, connect the External Volt Leads from the voltage regulator case ground to the alternator case.

ALTERNATOR

CASE

CASE

REGULATOR

| BATTERY | SOLENOID |

|

| |

CHASSIS |

| RELAY |

Figure 9

3.Run the engine at idle, but first momentarily boost it to 2000 Rpm to be sure the regulator has “cut in”.

4.Test Conclusion : The voltage reading should be less than 0.1 volt. If not, look for loose bolts, a damaged ground strap or corrosion.

EXTERNAL REGULATOR CAUTION

Always disconnect the regulator before checking alternator output with full field jumpers. Always disconnect the con- nector plug from the regulator before removing the regula- tor mounting screws. Removing the connection from an ungrounded regulator with the ignition switch on may de- stroy the regulator. Be sure to disconnect electric choke wire from stator terminal of alternator when diagnosing charging system.

Check electric choke wire for a bad ground condition.

LOAD REQUIREMENT TEST

This test indicates if the charging output is enough to supply the vehicle accessory load requirement.

1.While running the car, turn on all lights, air conditioning, fan, wipers, sound system, and any other accessories that will run continuously.

2.Operate the engine about 2000 RPM. The Battery Volts readout must be greater than the battery voltage at rest to show that all the current is being supplied by the charging output (over 13.0V is good).

3.If low, switch off extra loads one at a time to determine the output shortage.

FULL FIELDING AMPERAGE TEST

This test disconnects the voltage regulator and applies alternator full field current directly to the battery, to see if the alternator windings and diodes are okay. External and internal regulator units can be tested as follows:

DO NOT GUESS ABOUT TERMINALS. WRONG CONNEC- TIONS MAY RUIN AN ALTERNATOR.

8