present, loop operation may continue. If the bypass circuit is not present, loop operation will be halted while the self test of the FC interface runs.

When the self test completes successfully, the control line to the bypass circuit is disabled and the drive enters the

If the

Note. It is the responsibility of the systems integrator to assure that no temperature, energy, voltage haz- ard, or ESD potential hazard is presented during the hot connect/disconnect operation. Discharge the static electricity from the drive carrier prior to inserting it into the system.

Caution. The drive motor must come to a complete stop prior to changing the plane of operation. This time is required to insure data integrity.

6.2.4S.M.A.R.T.

S.M.A.R.T. is an acronym for

Note. The drive’s firmware monitors specific attributes for degradation over time but can’t predict instanta- neous drive failures.

Each monitored attribute has been selected to monitor a specific set of failure conditions in the operating per- formance of the drive and the thresholds are optimized to minimize “false” and “failed” predictions.

Controlling S.M.A.R.T.

The operating mode of S.M.A.R.T. is controlled by the DEXCPT and PERF bits on the Informational Exceptions Control mode page (1Ch). Use the DEXCPT bit to enable or disable the S.M.A.R.T. feature. Setting the DEX- CPT bit disables all S.M.A.R.T. functions. When enabled, S.M.A.R.T. collects

You can measure

You can interrogate the drive through the host to determine the time remaining before the next scheduled mea- surement and data logging process occurs. To accomplish this, issue a Log Sense command to log page 0x3E. This allows you to control when S.M.A.R.T. interruptions occur. Forcing S.M.A.R.T. with the RTZ command resets the timer.

Performance impact

S.M.A.R.T. attribute data is saved to the disc so that the events that caused a predictive failure can be recre- ated. The drive measures and saves parameters once every two hours subject to an idle period on the

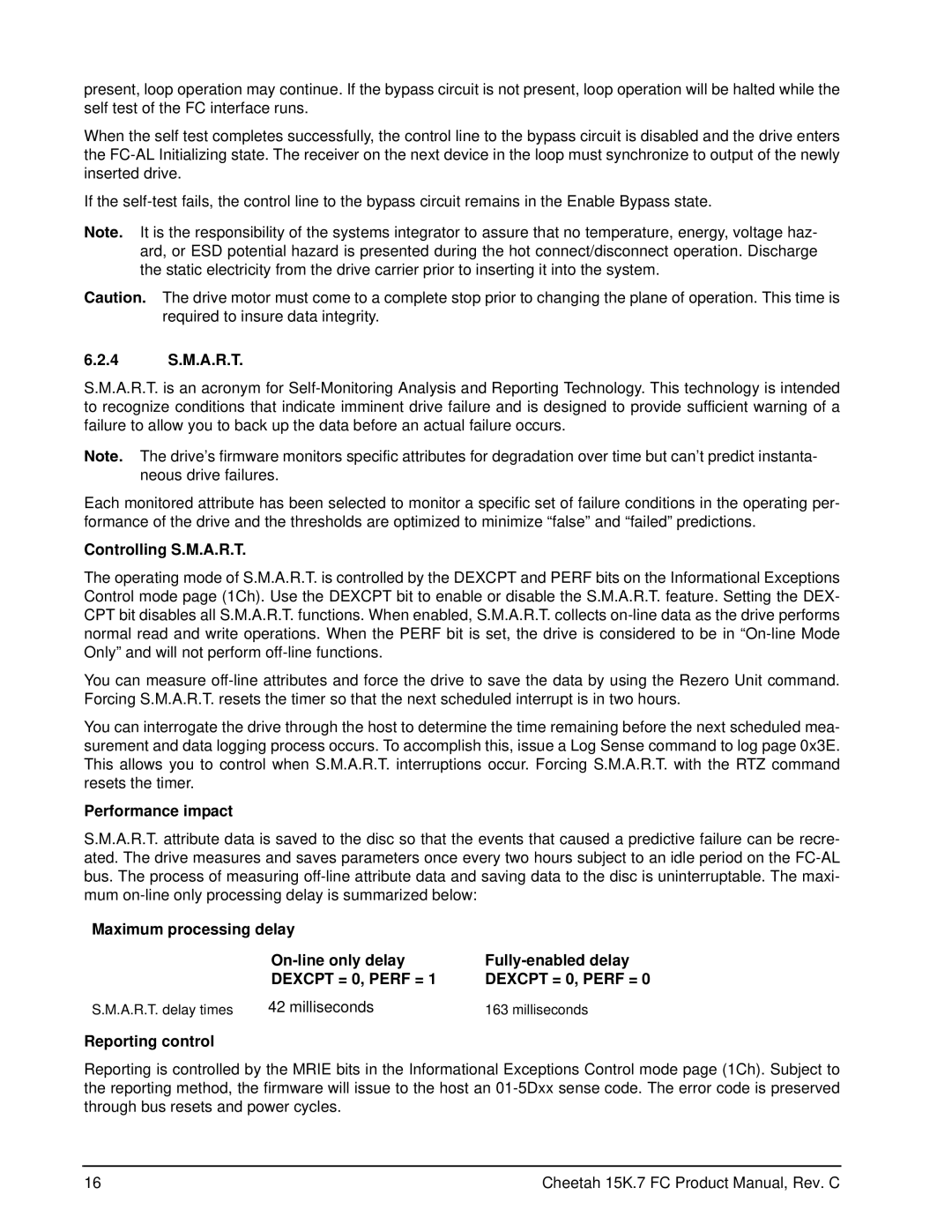

Maximum processing delay |

| |

| ||

| DEXCPT = 0, PERF = 1 | DEXCPT = 0, PERF = 0 |

S.M.A.R.T. delay times | 42 milliseconds | 163 milliseconds |

Reporting control

Reporting is controlled by the MRIE bits in the Informational Exceptions Control mode page (1Ch). Subject to the reporting method, the firmware will issue to the host an

16 | Cheetah 15K.7 FC Product Manual, Rev. C |