iii | ii | i | iii |

SERVICE AND

, iii | i | iiiiiii | iiii | iii |

FLEXIBLEPUMP COUPLER

The flexible pump coupler is a nylon "spider" insert, located between the pump and engine shaft. Over a period of time, the coupler wil! harden and deteriorate.

Replacement is needed if you detect vibration or noise coming from the area between the engine and the pump. If the coupler fails completely, you wil! experience a loss of power. For a replacement tlexible pump coupler, order part number

WARNING: NEVER HIT THE PUMP SHAFT IN ANY MANNER, AS ANY BLOW WILL CAUSE PERMANENT DAMAGE TO THE PUMP.

When replacing the flexible pump coupling, proceed as follows. Follow the instructions careully as the alignment is very critical.

•Disconnect the spark plug wire from the spark plug, and secure it away from the spark plug.

•Using a 1/2 inch wrench, remove three nuts and lock washers which secure the pump to the cou- pling shield. Two nuts are at the bottom corners and one is in the top center.

•Remove the pump.

•Rotate the engine by pulling starter handle until engine coupling half set screw is at bottom. Loosen set screw using 7/64 inch Allen wrench. Slide cou- pling half off of engine shaft.

•Loosen set screw on pump coupling half, and remove coupling hail.

•Slide new engine coupling half onto the engine shaft until the end of the shaft is flush with the inner

portion of the coupling half. (There must be space between end of engine support bracket and cou- pling half.) Tighten set screw.

•Install pump coupling half and key on pump shaft. Rotate coupling half until set screw faces down. Do not tighten set screw.

•Install nylon "spider" onto engine coupling half.

•Align pump coupling half with nylon "spider" by rotating engine using starter handle. Slide coupling half into place while guiding three mounting bolts through holes in pump support bracket.

•Secure with nuts and washers removed earlier.

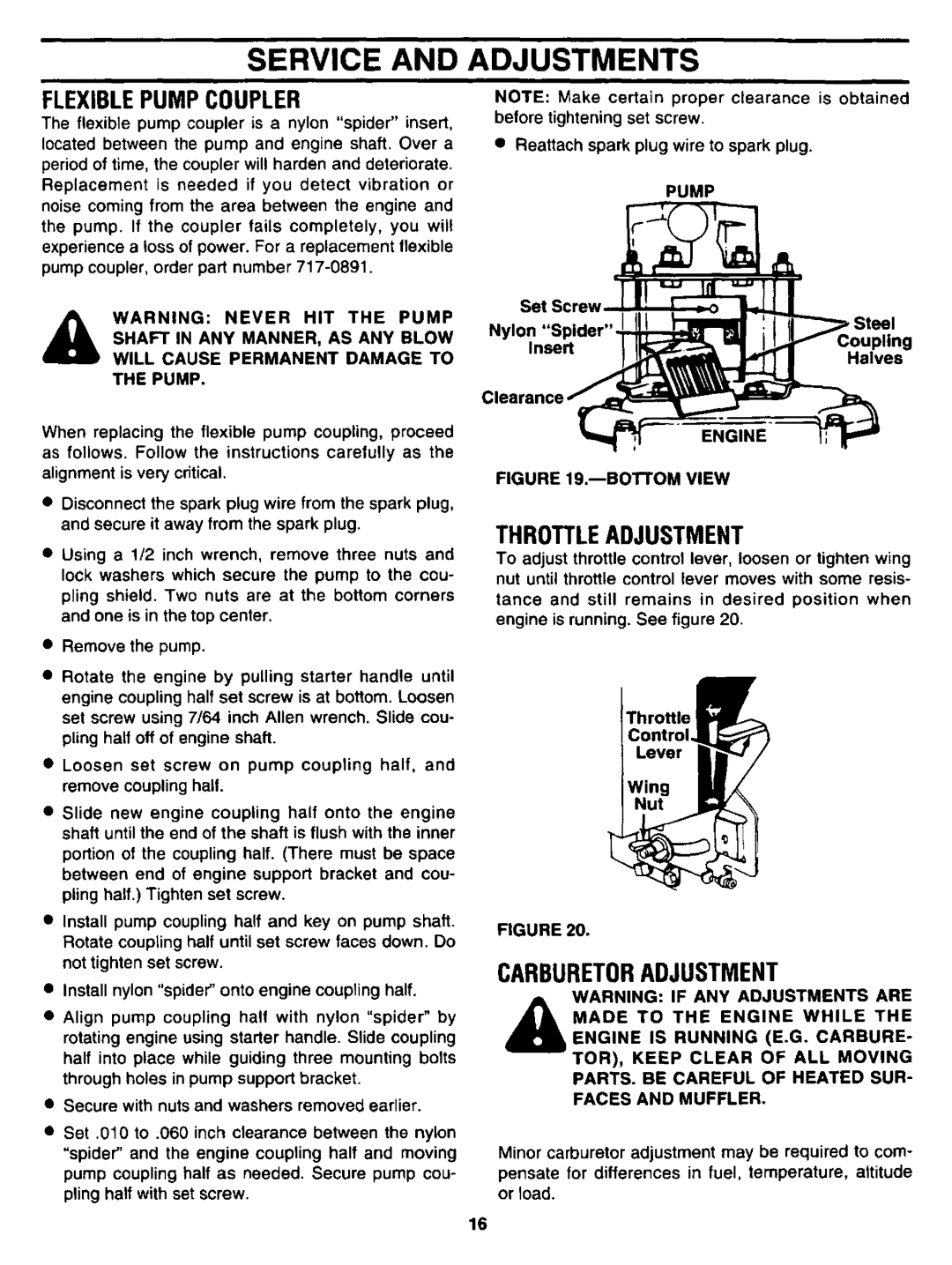

•Set .010 to .060 inch clearance between the nylon "spider" and the engine coupling half and moving pump coupling half as needed. Secure pump cou- pling half with set screw.

i iiiii | iiiiii | in |

ADJUSTMENTS

IIIIIII | i | z= | m |

NOTE: Make certain proper clearance is obtained before tightening set screw.

•Reattach spark plug wire to spark plug.

PUMP

Set Screw

Nylon

Insertpiing

Halves

ENGINE

FIGURE 19.--BOTTOM VIEW

THROTTLEADJUSTMENT

To adjust throttle control lever, loosen or tighten wing nut until throttle control lever moves with some resis- tance and still remains in desired position when engine is running. See figure 20.

Throttle

Control.

Lever

Wing

Nut

FIGURE 20.

CARBURETORADJUSTMENT

WARNING: IF ANY ADJUSTMENTS ARE

MADE TO THE ENGINE WHILE THE ENGINE IS RUNNING (E.G. CARBURE-

TOR), KEEP CLEAR OF ALL MOVING PARTS. BE CAREFUL OF HEATED SUR-

FACES AND MUFFLER.

Minor carburetor adjustment may be required to com-

pensate for differences in fuel, temperature, altitude or load.

16