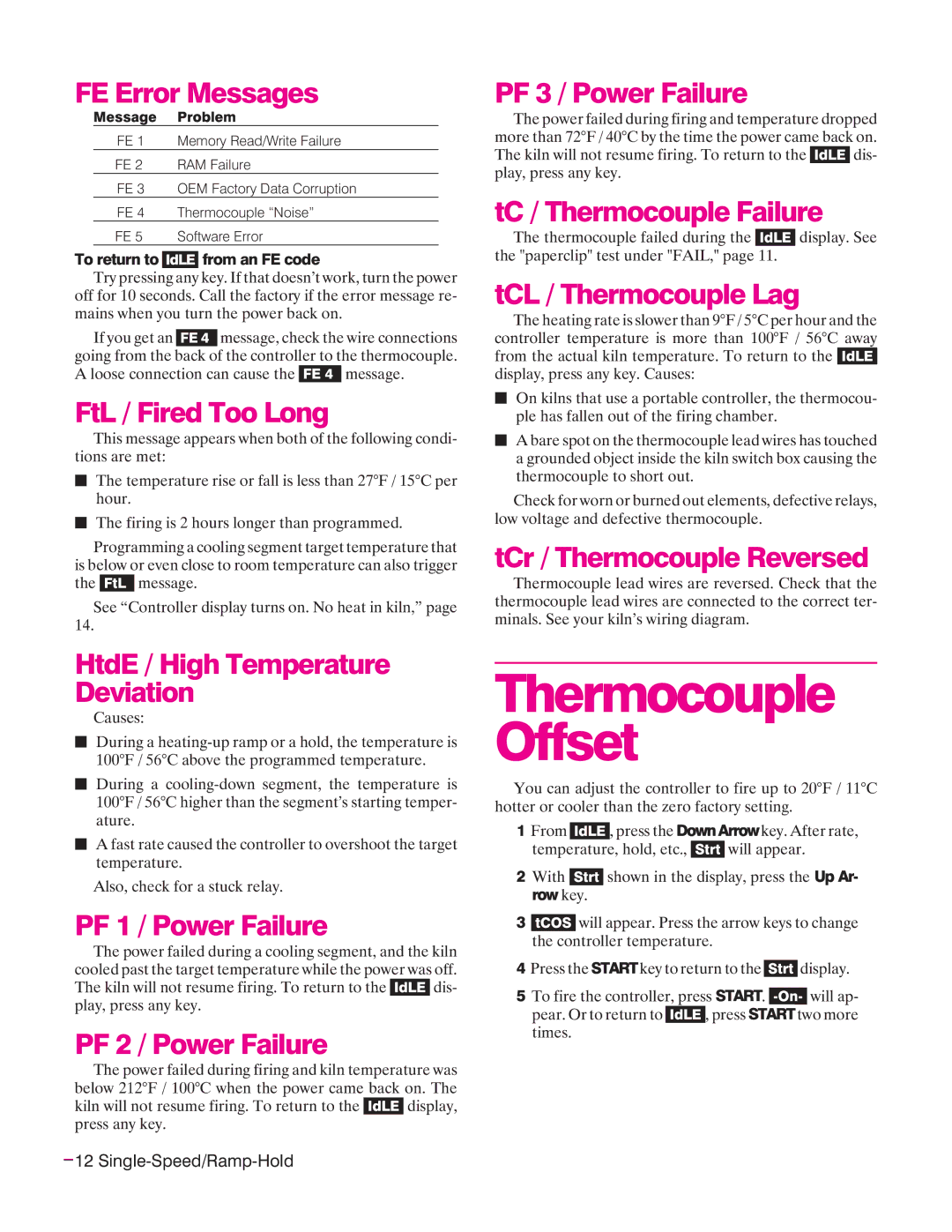

FE Error Messages

| FE 1 |

| Memory Read/Write Failure |

| FE 2 |

| RAM Failure |

| FE 3 |

| OEM Factory Data Corruption |

| FE 4 |

| Thermocouple “Noise” |

To | FE 5 |

| Software Error |

return to |

| from an FE code | |

|

Try pressing any key. If that doesn’t work, turn the power

off for 10 seconds. Call the factory if the error message re- | |

mains when you turn the power back on. | |

If you get an | message, check the wire connections |

going from the back of the controller to the thermocouple. | |

A loose connection can cause the | message. |

FtL / Fired Too Long

This message appears when both of the following condi- tions are met:

■The temperature rise or fall is less than 27°F / 15°C per hour.

■The firing is 2 hours longer than programmed.

Programming a cooling segment target temperaturethat is below or even close to room temperature can also trigger

the ![]() message.

message.

14.See “Controller display turns on. No heat in kiln,” page

HtdE / High Temperature Deviation

Causes:

■During a

■During a

■A fast rate caused the controller to overshoot the target temperature.

Also, check for a stuck relay.

PF 1 / Power Failure

The power failed during a cooling segment, and the kiln cooled past the target temperature while the power was off.

The kiln will not resume firing. To return to the ![]()

![]()

![]() dis- play, press any key.

dis- play, press any key.

PF 2 / Power Failure

The power failed during firing and kiln temperature was below 212°F / 100°C when the power came back on. The

kiln will not resume firing. To return to the ![]()

![]()

![]() display, press any key.

display, press any key.

PF 3 / Power Failure

The power failed during firing and temperaturedropped more than 72°F / 40°C by the time the power came back on.

The kiln will not resume firing. To return to the ![]()

![]()

![]() dis- play, press any key.

dis- play, press any key.

tC / Thermocouple Failure

The thermocouple failed during the ![]()

![]()

![]() display. See the "paperclip" test under "FAIL," page 11.

display. See the "paperclip" test under "FAIL," page 11.

tCL / Thermocouple Lag

The heating rate is slower than 9°F / 5°C per hour and the controller temperature is more than 100°F / 56°C away from the actual kiln temperature. To return to the ![]()

![]()

![]() display, press any key. Causes:

display, press any key. Causes:

■On kilns that use a portable controller, the thermocou- ple has fallen out of the firing chamber.

■A bare spot on the thermocouple lead wires has touched a grounded object inside the kiln switch box causing the thermocouple to short out.

Check for worn or burned out elements, defective relays, low voltage and defective thermocouple.

tCr / Thermocouple Reversed

Thermocouple lead wires are reversed. Check that the thermocouple lead wires are connected to the correct ter- minals. See your kiln’s wiring diagram.

Thermocouple Offset

You can adjust the controller to fire up to 20°F / 11°C hotter or cooler than the zero factory setting.

From |

|

|

| , press the |

| key. After rate, | |

|

|

| |||||

temperature, | hold, etc., |

| will appear. | ||||

| |||||||

With |

| shown in the display, press the | |||||

| |||||||

key. |

|

|

|

| |||

will appear. Press the arrow keys to change the controller temperature.

![]() Press the

Press the![]()

![]()

![]() key to return to the

key to return to the ![]() display.

display.

To fire the controller, press ![]()

![]() .

. ![]()

![]() will ap-

will ap-

pear. Or to return to ![]()

![]() , press

, press ![]()

![]() two more times.

two more times.

12