Ramp-Hold

Mode

You can make your own firing programs and store them in the controller’s memory. A firing program tells the kiln how fast to fire, and to what temperature. The simplest pro- gram is one segment. You can use up to 8 segments with your controller in

Each segment includes a firing rate and firing tempera- ture. You can also soak, or hold, the temperaturefor a spec- ified period.

The Parts of a Segment

■Rate (temperature change in degrees per hour)

■Target temperature

■Hold at the target temperature (not always used)

The controller can retain four programs in memory even when power is turned off. Programs are numbered Pro1 - Pro4.

The first message to appear after you plug in your Sentry | |||||||||||||||||||

Xpress is |

|

|

|

|

| . Press |

| . Then use the |

| key | |||||||||

to scroll | through | these messages: |

|

|

|

|

|

|

| ||||||||||

|

|

|

|

|

| ||||||||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| . |

|

|

|

To use | select | |

. You do that by pressing the | key after |

|

appears. Then follow the boxed instructions on page 8 to enter temperature, heating rate, etc.

is Program 1. When you fire the kiln again, you | |

can repeat Program 1 by selecting | . (See page 4.) |

When you are ready to fire a different program, select , which is Program 2. Then enter temperatures, heat-

ing rates, etc. Select Program 3 and 4 the same way.

A program can have up to 8 segments, but you don’t have to use all 8 segments. Use only the number needed per fir- ing. Often one segment is all you will need. Zero out the un- used segments. The instructions on page 8 explain how to do that.

To

Programming a

Cooling Segment

For controlled cooling, program a segment to a lower target temperature than that of the preceding segment.

Example: You fire at a rate of 500°F per hour to 1450°F with your first segment. You want the kiln to cool at a rate of 100°F per hour down to 700°F. Here is how you would program the two segments:

Segment | Rate | Temp. | Hold |

°F/°C | °F/°C | ||

1 | 500/277 | 1450/788 | 00.00 |

2 | 100/55 | 700/371 | 00.00 |

The first segment is the heating segment. The second one is the cooling segment. The controller does not use mi- nus numbers for cooling. Just enter a lower target tempera- ture than that of the previous segment.

If you prop the lid or door for a fast cooling, program a fast cooling rate for that segment. If you lower the tempera- ture quickly by propping the lid but program a slow cooling rate, the controller will just raise the temperature again.

Example: Some glass artists

Note: During fast cooling, do not open the door all the way. Do not

Note: You may get an FTL error message (page 12) if you program a

ARamp-Hold Practice Program

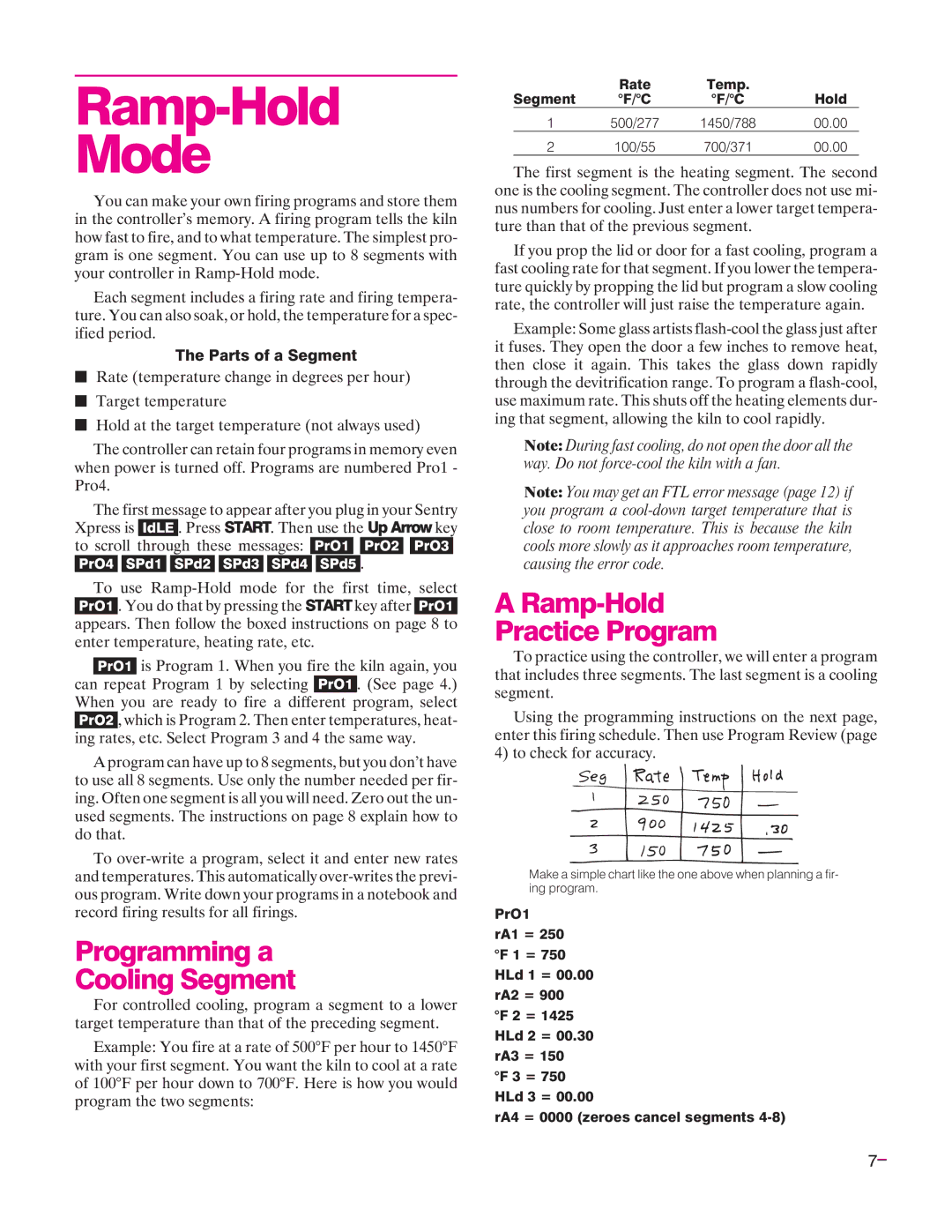

To practice using the controller, we will enter a program that includes three segments. The last segment is a cooling segment.

Using the programming instructions on the next page, enter this firing schedule. Then use Program Review (page 4) to check for accuracy.

Make a simple chart like the one above when planning a fir- ing program.

PrO1

rA1 = 250 °F 1 = 750 HLd 1 = 00.00 rA2 = 900

°F 2 = 1425 HLd 2 = 00.30 rA3 = 150

°F 3 = 750 HLd 3 = 00.00

rA4 = 0000 (zeroes cancel segments

7