MAINTENANCE

MAINTENANCE

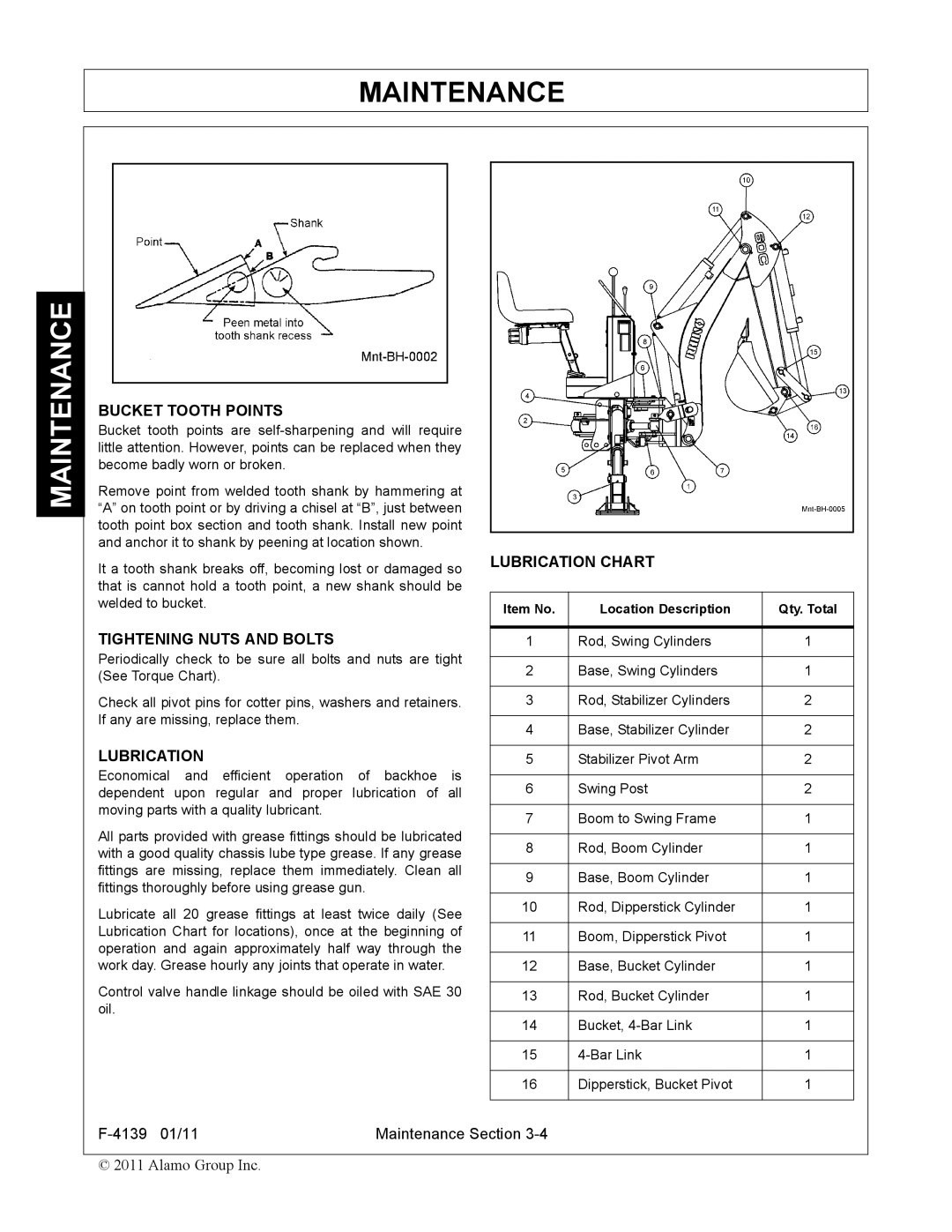

BUCKET TOOTH POINTS

Bucket tooth points are

Remove point from welded tooth shank by hammering at “A” on tooth point or by driving a chisel at “B”, just between tooth point box section and tooth shank. Install new point and anchor it to shank by peening at location shown.

It a tooth shank breaks off, becoming lost or damaged so that is cannot hold a tooth point, a new shank should be welded to bucket.

TIGHTENING NUTS AND BOLTS

Periodically check to be sure all bolts and nuts are tight (See Torque Chart).

Check all pivot pins for cotter pins, washers and retainers. If any are missing, replace them.

LUBRICATION

Economical and efficient operation of backhoe is dependent upon regular and proper lubrication of all moving parts with a quality lubricant.

All parts provided with grease fittings should be lubricated with a good quality chassis lube type grease. If any grease fittings are missing, replace them immediately. Clean all fittings thoroughly before using grease gun.

Lubricate all 20 grease fittings at least twice daily (See Lubrication Chart for locations), once at the beginning of operation and again approximately half way through the work day. Grease hourly any joints that operate in water.

Control valve handle linkage should be oiled with SAE 30 oil.

LUBRICATION CHART

Item No. | Location Description | Qty. Total |

|

|

|

1 | Rod, Swing Cylinders | 1 |

|

|

|

2 | Base, Swing Cylinders | 1 |

|

|

|

3 | Rod, Stabilizer Cylinders | 2 |

|

|

|

4 | Base, Stabilizer Cylinder | 2 |

|

|

|

5 | Stabilizer Pivot Arm | 2 |

|

|

|

6 | Swing Post | 2 |

|

|

|

7 | Boom to Swing Frame | 1 |

|

|

|

8 | Rod, Boom Cylinder | 1 |

|

|

|

9 | Base, Boom Cylinder | 1 |

|

|

|

10 | Rod, Dipperstick Cylinder | 1 |

|

|

|

11 | Boom, Dipperstick Pivot | 1 |

|

|

|

12 | Base, Bucket Cylinder | 1 |

|

|

|

13 | Rod, Bucket Cylinder | 1 |

|

|

|

14 | Bucket, | 1 |

|

|

|

15 | 1 | |

|

|

|

16 | Dipperstick, Bucket Pivot | 1 |

|

|

|

Maintenance Section |

© 2011 Alamo Group Inc.