DESCRIPTION

Additional Safety Precautions (cont.)

WARNING!

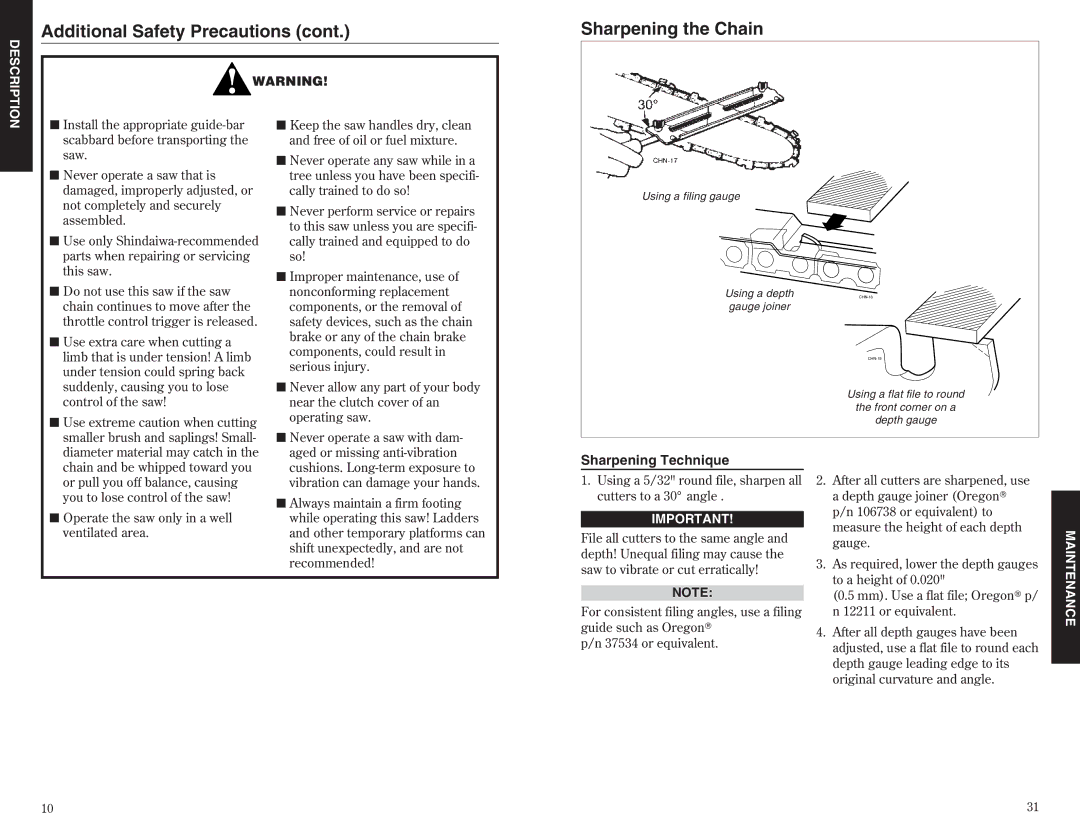

Sharpening the Chain

■ Install the appropriate |

scabbard before transporting the |

saw. |

■ Never operate a saw that is |

damaged, improperly adjusted, or |

not completely and securely |

assembled. |

■ Use only |

parts when repairing or servicing |

this saw. |

■ Do not use this saw if the saw |

chain continues to move after the |

throttle control trigger is released. |

■ Use extra care when cutting a |

limb that is under tension! A limb |

under tension could spring back |

suddenly, causing you to lose |

control of the saw! |

■ Use extreme caution when cutting |

smaller brush and saplings! Small- |

diameter material may catch in the |

chain and be whipped toward you |

■ Keep the saw handles dry, clean |

and free of oil or fuel mixture. |

■ Never operate any saw while in a |

tree unless you have been specifi- |

cally trained to do so! |

■ Never perform service or repairs |

to this saw unless you are specifi- |

cally trained and equipped to do |

so! |

■ Improper maintenance, use of |

nonconforming replacement |

components, or the removal of |

safety devices, such as the chain |

brake or any of the chain brake |

components, could result in |

serious injury. |

■ Never allow any part of your body |

near the clutch cover of an |

operating saw. |

■ Never operate a saw with dam- |

aged or missing |

cushions. |

Using a filing gauge

Using a depth | |

gauge joiner |

|

Using a flat file to round

the front corner on a

depth gauge

Sharpening Technique

or pull you off balance, causing |

you to lose control of the saw! |

■ Operate the saw only in a well |

ventilated area. |

vibration can damage your hands. |

■ Always maintain a firm footing |

while operating this saw! Ladders |

and other temporary platforms can |

shift unexpectedly, and are not |

recommended! |

1.Using a 5/32" round file, sharpen all cutters to a 30° angle .

IMPORTANT!

File all cutters to the same angle and depth! Unequal filing may cause the saw to vibrate or cut erratically!

NOTE:

For consistent filing angles, use a filing guide such as Oregon®

p/n 37534 or equivalent.

2.After all cutters are sharpened, use a depth gauge joiner (Oregon® p/n 106738 or equivalent) to measure the height of each depth gauge.

3.As required, lower the depth gauges to a height of 0.020"

(0.5 mm). Use a flat file; Oregon® p/ n 12211 or equivalent.

4.After all depth gauges have been adjusted, use a flat file to round each depth gauge leading edge to its original curvature and angle.

MAINTENANCE

10 | 31 |