4 Troubleshooting

4Troubleshooting the SAMMS-LV Device

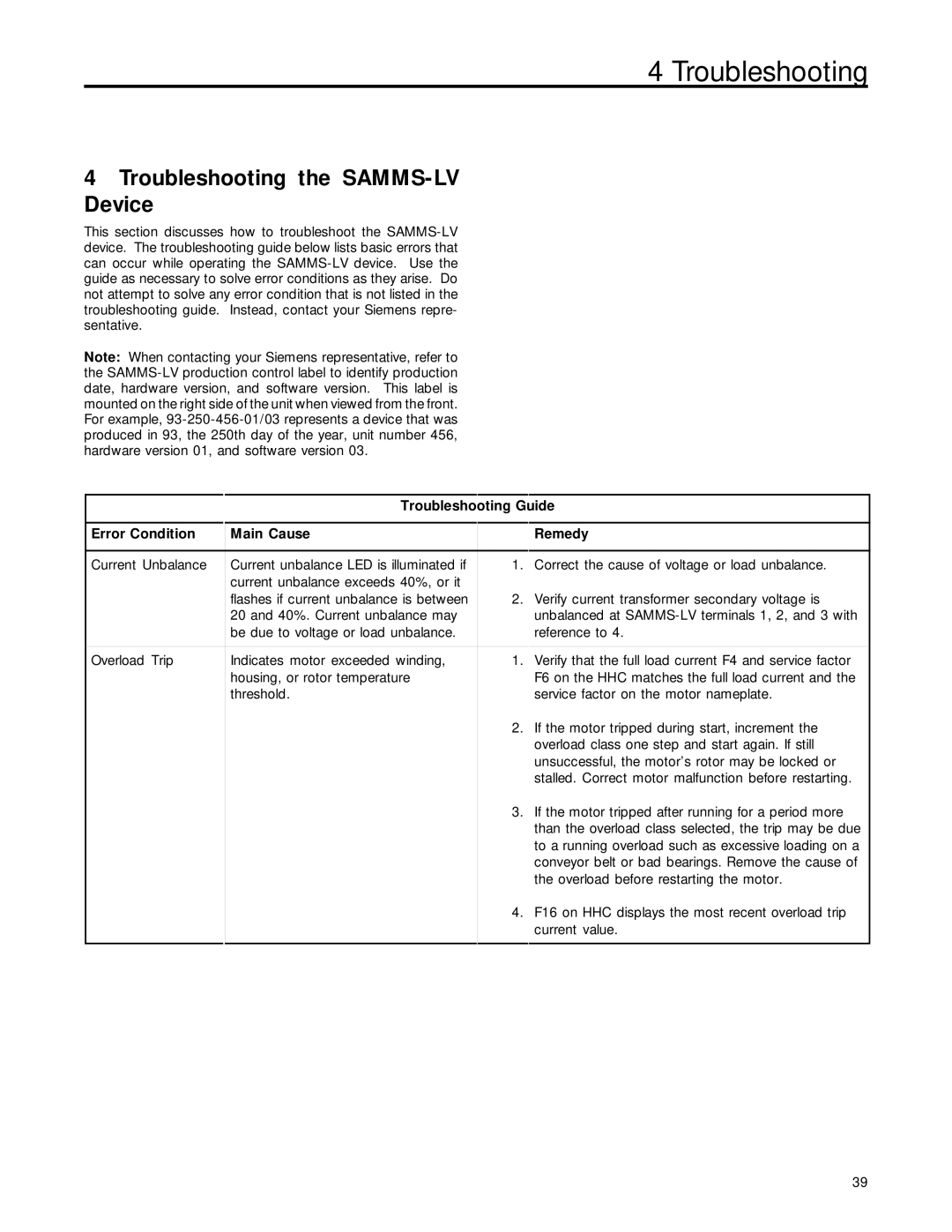

This section discusses how to troubleshoot the

Note: When contacting your Siemens representative, refer to the

|

| Troubleshooting Guide | ||

|

|

|

|

|

Error Condition |

| Main Cause |

| Remedy |

|

|

|

|

|

Current Unbalance |

| Current unbalance LED is illuminated if | 1. | Correct the cause of voltage or load unbalance. |

|

| current unbalance exceeds 40%, or it |

|

|

|

| flashes if current unbalance is between | 2. | Verify current transformer secondary voltage is |

|

| 20 and 40%. Current unbalance may |

| unbalanced at |

|

| be due to voltage or load unbalance. |

| reference to 4. |

Overload Trip |

| Indicates motor exceeded winding, | 1. | Verify that the full load current F4 and service factor |

|

| housing, or rotor temperature |

| F6 on the HHC matches the full load current and the |

|

| threshold. |

| service factor on the motor nameplate. |

|

|

| 2. | If the motor tripped during start, increment the |

|

|

|

| overload class one step and start again. If still |

|

|

|

| unsuccessful, the motor’s rotor may be locked or |

|

|

|

| stalled. Correct motor malfunction before restarting. |

|

|

| 3. | If the motor tripped after running for a period more |

|

|

|

| than the overload class selected, the trip may be due |

|

|

|

| to a running overload such as excessive loading on a |

|

|

|

| conveyor belt or bad bearings. Remove the cause of |

|

|

|

| the overload before restarting the motor. |

|

|

| 4. | F16 on HHC displays the most recent overload trip |

|

|

|

| current value. |

|

|

|

|

|

39