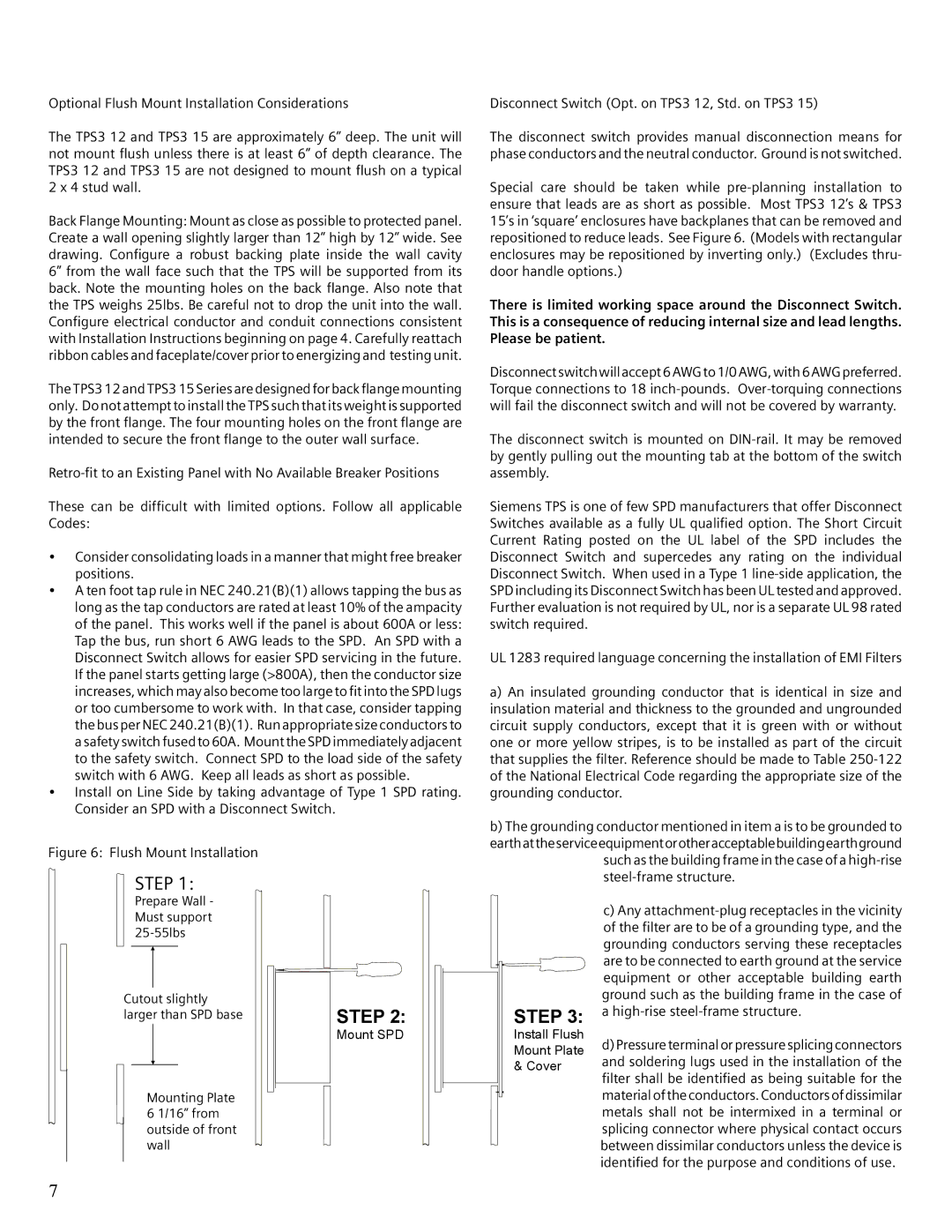

Optional Flush Mount Installation Considerations

The TPS3 12 and TPS3 15 are approximately 6” deep. The unit will not mount flush unless there is at least 6” of depth clearance. The TPS3 12 and TPS3 15 are not designed to mount flush on a typical 2 x 4 stud wall.

Back Flange Mounting: Mount as close as possible to protected panel. Create a wall opening slightly larger than 12” high by 12” wide. See drawing. Configure a robust backing plate inside the wall cavity 6” from the wall face such that the TPS will be supported from its back. Note the mounting holes on the back flange. Also note that the TPS weighs 25lbs. Be careful not to drop the unit into the wall. Configure electrical conductor and conduit connections consistent with Installation Instructions beginning on page 4. Carefully reattach ribbon cables and faceplate/cover prior to energizing and testing unit.

The TPS3 12 and TPS3 15 Series are designed for back flange mounting only. Do not attempt to install the TPS such that its weight is supported by the front flange. The four mounting holes on the front flange are intended to secure the front flange to the outer wall surface.

These can be difficult with limited options. Follow all applicable Codes:

•Consider consolidating loads in a manner that might free breaker positions.

•A ten foot tap rule in NEC 240.21(B)(1) allows tapping the bus as long as the tap conductors are rated at least 10% of the ampacity of the panel. This works well if the panel is about 600A or less: Tap the bus, run short 6 AWG leads to the SPD. An SPD with a Disconnect Switch allows for easier SPD servicing in the future. If the panel starts getting large (>800A), then the conductor size increases, which may also become too large to fit into the SPD lugs or too cumbersome to work with. In that case, consider tapping the bus per NEC 240.21(B)(1). Run appropriate size conductors to a safety switch fused to 60A. Mount the SPD immediately adjacent to the safety switch. Connect SPD to the load side of the safety switch with 6 AWG. Keep all leads as short as possible.

•Install on Line Side by taking advantage of Type 1 SPD rating. Consider an SPD with a Disconnect Switch.

Figure 6: Flush Mount Installation

Disconnect Switch (Opt. on TPS3 12, Std. on TPS3 15)

The disconnect switch provides manual disconnection means for phase conductors and the neutral conductor. Ground is not switched.

Special care should be taken while

There is limited working space around the Disconnect Switch. This is a consequence of reducing internal size and lead lengths. Please be patient.

Disconnect switch will accept 6 AWG to 1/0 AWG, with 6 AWG preferred. Torque connections to 18

The disconnect switch is mounted on

Siemens TPS is one of few SPD manufacturers that offer Disconnect Switches available as a fully UL qualified option. The Short Circuit Current Rating posted on the UL label of the SPD includes the Disconnect Switch and supercedes any rating on the individual Disconnect Switch. When used in a Type 1

UL 1283 required language concerning the installation of EMI Filters

a) An insulated grounding conductor that is identical in size and |

insulation material and thickness to the grounded and ungrounded |

circuit supply conductors, except that it is green with or without |

one or more yellow stripes, is to be installed as part of the circuit |

that supplies the filter. Reference should be made to Table |

of the National Electrical Code regarding the appropriate size of the |

grounding conductor. |

b) The grounding conductor mentioned in item a is to be grounded to |

earthattheserviceequipmentorotheracceptablebuildingearthground |

such as the building frame in the case of a |

Step 1:

Prepare Wall - Must support

Cutout slightly larger than SPD base

Mounting Plate 6 1/16” from outside of front wall

Step 2:

Mount SPD

Step 3:

Install Flush

Mount Plate

& Cover

c)Any

d)Pressure terminal or pressure splicing connectors and soldering lugs used in the installation of the filter shall be identified as being suitable for the material of the conductors. Conductors of dissimilar metals shall not be intermixed in a terminal or splicing connector where physical contact occurs between dissimilar conductors unless the device is identified for the purpose and conditions of use.

7