SM 1619X04463

METAL CUTTING

When cutting metal clamp material down. Be extra certain that you move the saw along slowly. Use lower speeds. Do not twist, bend, or force the blade. If the saw jumps or bounces, use a blade with finer teeth. If the blade seems clogged when cutting soft metal, use a blade with coarser teeth.

For easier cutting, lubricate the blade with a stick of cutting wax, if available, or cutting oil when cutting steel. Thin metal should be

sandwiched between two pieces of wood or tightly clamped on a single piece of wood (wood on top of the metal). Draw the cut lines or design on the top piece of wood.

When cutting aluminum extrusion or angle iron, clamp the work in a bench vise and saw close to the vise jaws.

When sawing tubing and the diameter is larger than the blade is deep, cut through the wall of the tubing and then insert the blade into the cut rotating the tube as you saw.

RIP FENCE AND CIRCLE CUTTING GUIDE

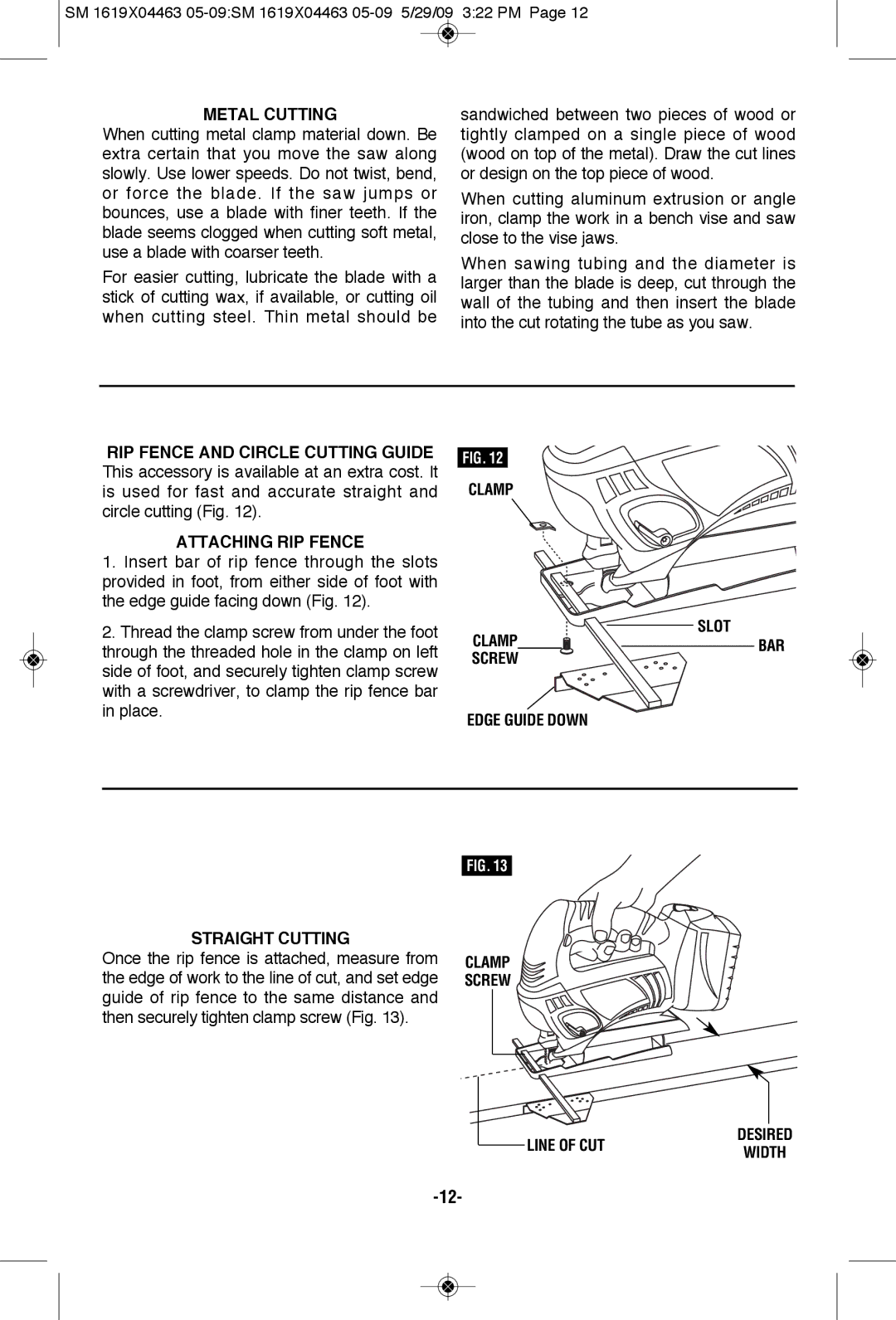

This accessory is available at an extra cost. It is used for fast and accurate straight and circle cutting (Fig. 12).

ATTACHING RIP FENCE

1.Insert bar of rip fence through the slots provided in foot, from either side of foot with the edge guide facing down (Fig. 12).

2.Thread the clamp screw from under the foot through the threaded hole in the clamp on left side of foot, and securely tighten clamp screw with a screwdriver, to clamp the rip fence bar in place.

FIG. 12

CLAMP

CLAMP | SLOT | |

BAR | ||

SCREW | ||

| ||

EDGE GUIDE DOWN |

|

STRAIGHT CUTTING

Once the rip fence is attached, measure from the edge of work to the line of cut, and set edge guide of rip fence to the same distance and then securely tighten clamp screw (Fig. 13).

FIG. 13

CLAMP SCREW

LINE OF CUT | DESIRED | |

WIDTH | ||

|