SM 1619X04463

CUTTING WITH A STRAIGHTEDGE

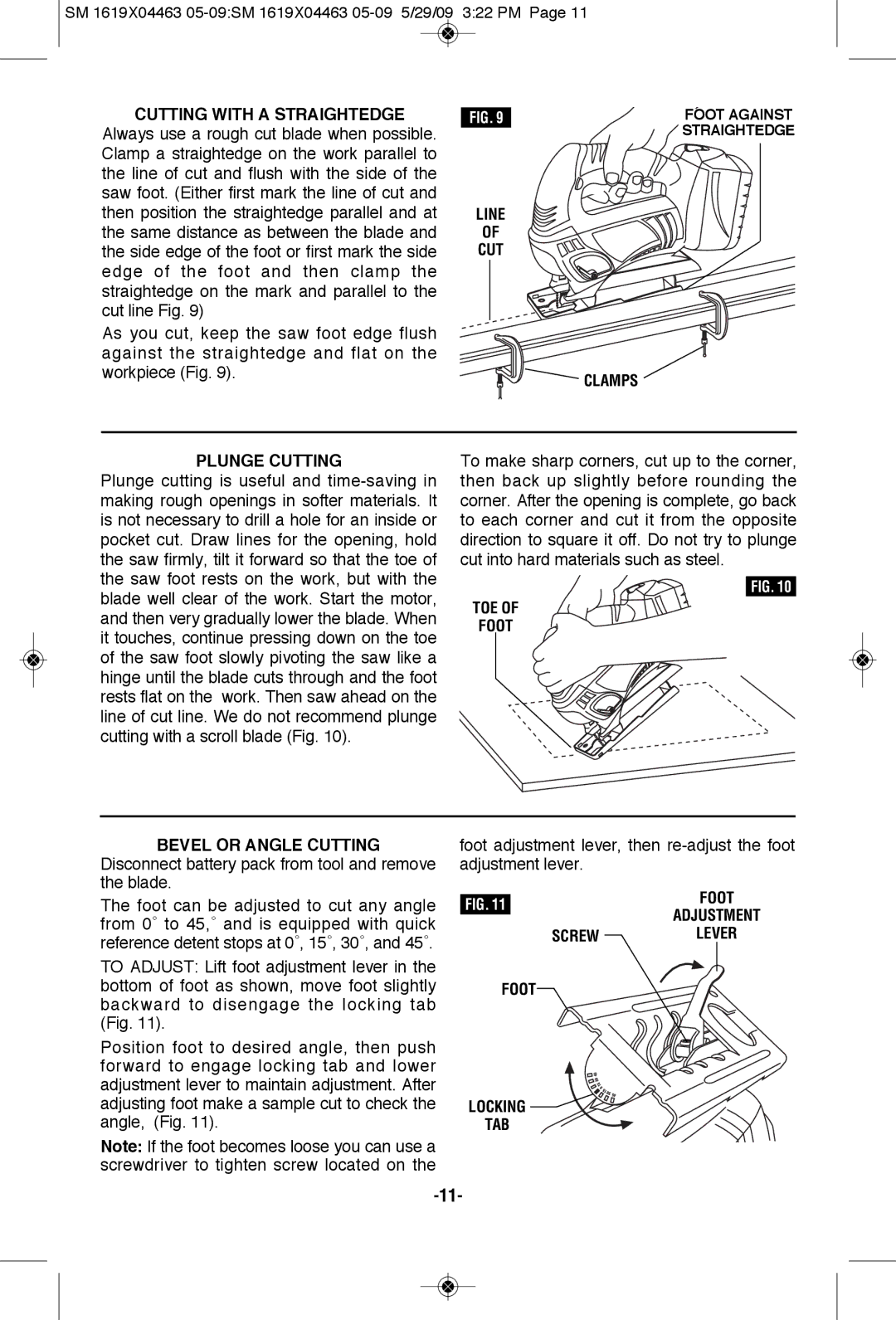

Always use a rough cut blade when possible. Clamp a straightedge on the work parallel to the line of cut and flush with the side of the saw foot. (Either first mark the line of cut and then position the straightedge parallel and at the same distance as between the blade and the side edge of the foot or first mark the side edge of the foot and then clamp the straightedge on the mark and parallel to the cut line Fig. 9)

As you cut, keep the saw foot edge flush against the straightedge and flat on the workpiece (Fig. 9).

FIG. 9 | FOOT AGAINST |

| STRAIGHTEDGE |

LINE

OF

CUT

CLAMPS

PLUNGE CUTTING

Plunge cutting is useful and

To make sharp corners, cut up to the corner, then back up slightly before rounding the corner. After the opening is complete, go back to each corner and cut it from the opposite direction to square it off. Do not try to plunge cut into hard materials such as steel.

FIG. 10

TOE OF FOOT

BEVEL OR ANGLE CUTTING

Disconnect battery pack from tool and remove the blade.

The foot can be adjusted to cut any angle from 0˚ to 45,˚ and is equipped with quick reference detent stops at 0˚, 15˚, 30˚, and 45˚.

TO ADJUST: Lift foot adjustment lever in the bottom of foot as shown, move foot slightly backward to disengage the locking tab (Fig. 11).

Position foot to desired angle, then push forward to engage locking tab and lower adjustment lever to maintain adjustment. After adjusting foot make a sample cut to check the angle, (Fig. 11).

Note: If the foot becomes loose you can use a screwdriver to tighten screw located on the

foot adjustment lever, then

FIG. 11 | FOOT | |

ADJUSTMENT | ||

| ||

SCREW | LEVER | |

FOOT |

| |

LOCKING |

| |

TAB |

|