HD5860 specifications

The Skil HD5860 is a powerful and versatile tool designed for both professional and amateur woodworkers. This heavy-duty saw is renowned for its exceptional performance, precision, and advanced features, making it a must-have for anyone looking to take their woodworking projects to the next level.One of the standout features of the HD5860 is its robust 14-amp motor, which delivers fast and efficient cutting power. With the ability to reach speeds of up to 5,300 RPM, this saw can easily tackle a variety of materials, including hardwood, softwood, and engineered lumber. Its high-speed performance ensures clean cuts with minimal effort, allowing users to take on even the most challenging projects.

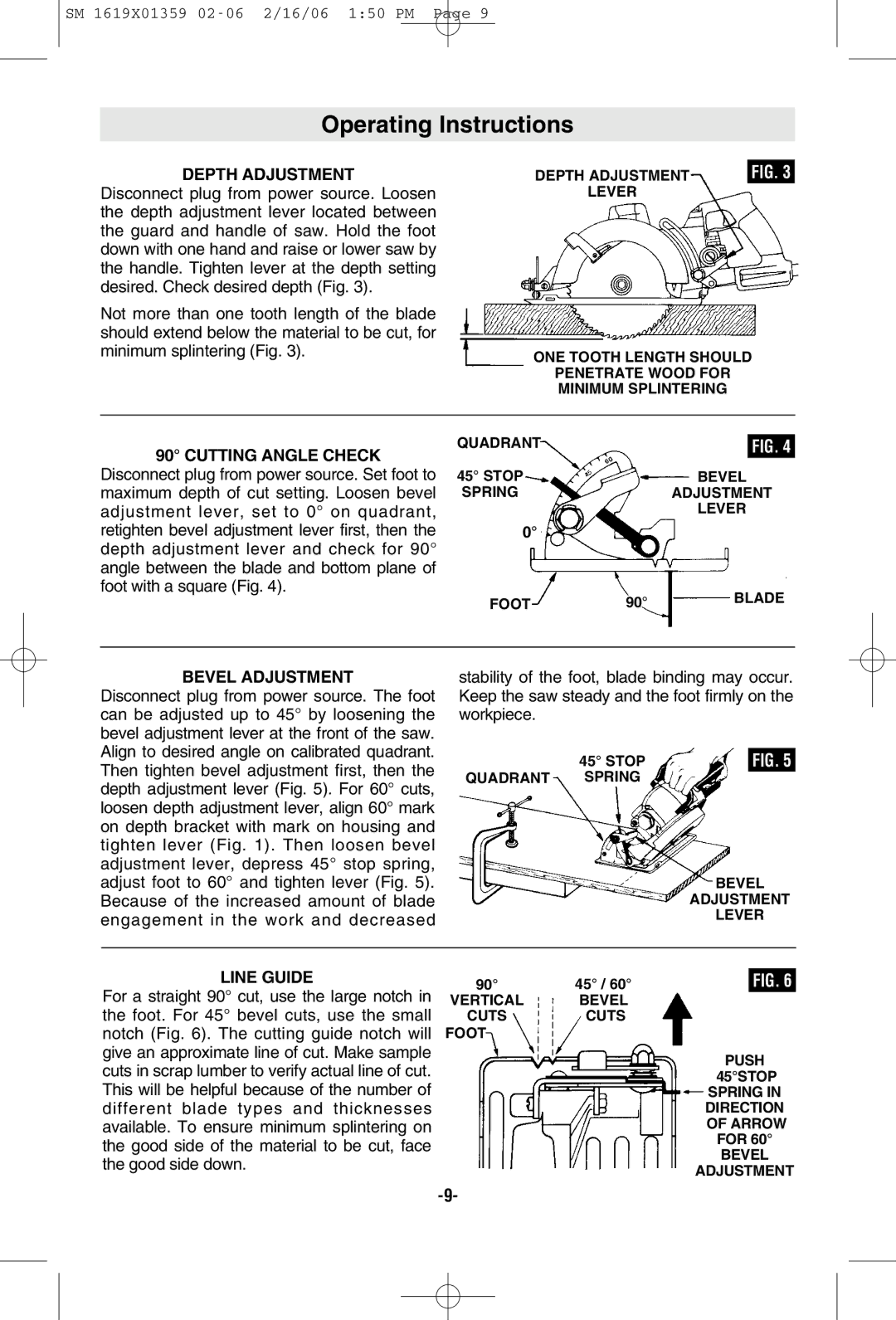

The Skil HD5860 is equipped with a lightweight aluminum base that enhances stability and reduces vibration during operation. This design feature not only improves accuracy but also extends the overall lifespan of the tool. The adjustable bevel angle, which can be set up to 45 degrees, adds versatility, enabling users to make angled cuts effortlessly. Whether you're cross-cutting or making compound angles, this saw provides the flexibility needed for a wide range of applications.

In terms of safety, the HD5860 includes several important features designed to protect the user during operation. The blade guard ensures safe cutting by covering the blade when not in use, while the electric brake stops the blade quickly once the trigger is released. Additionally, the onboard dust port helps maintain a cleaner workspace by connecting to a vacuum system, reducing dust and debris accumulation during cutting.

Another key characteristic is the laser guide system, which projects a line onto the workpiece, allowing for precise alignment and cuts. This feature significantly enhances accuracy, making it easier to follow cutting lines without second-guessing. The saw also comes with a durable carbide-tipped blade, ensuring long-lasting performance and cutting efficiency.

Overall, the Skil HD5860 combines power, precision, and safety in one tool, making it an excellent choice for woodworkers of all skill levels. With its advanced features and reliable performance, this saw is a valuable addition to any workshop, enabling users to achieve professional-quality results with ease. Whether you're undertaking a detailed woodworking project or simply need to make quick cuts, the Skil HD5860 proves to be a dependable partner in your woodworking endeavors.