Maintenance (Continued)

! | WARNING | ! |

DO NOT attempt any maintenance, adjustments or service with engine and blade running. STOP engine and blade. Disconnect spark plug wire and secure away from spark plug. Engine and components are HOT. Avoid serious burns, allow sufficient time for all components to cool.

Driven Disc Ring Replacement (Continued)

2.Using needle nose pliers, unhook the drive spring (A, Figure 31) and slide the driven disc assembly off the hex shaft.

3.Remove the five machine screws (A, Figure 32) and plate (B) which secure the rubber ring (C) to the driven disc hub (D).

4.Install a new rubber ring.

5.Reverse the above procedures for reassembly and installation of the driven disc assembly.

A

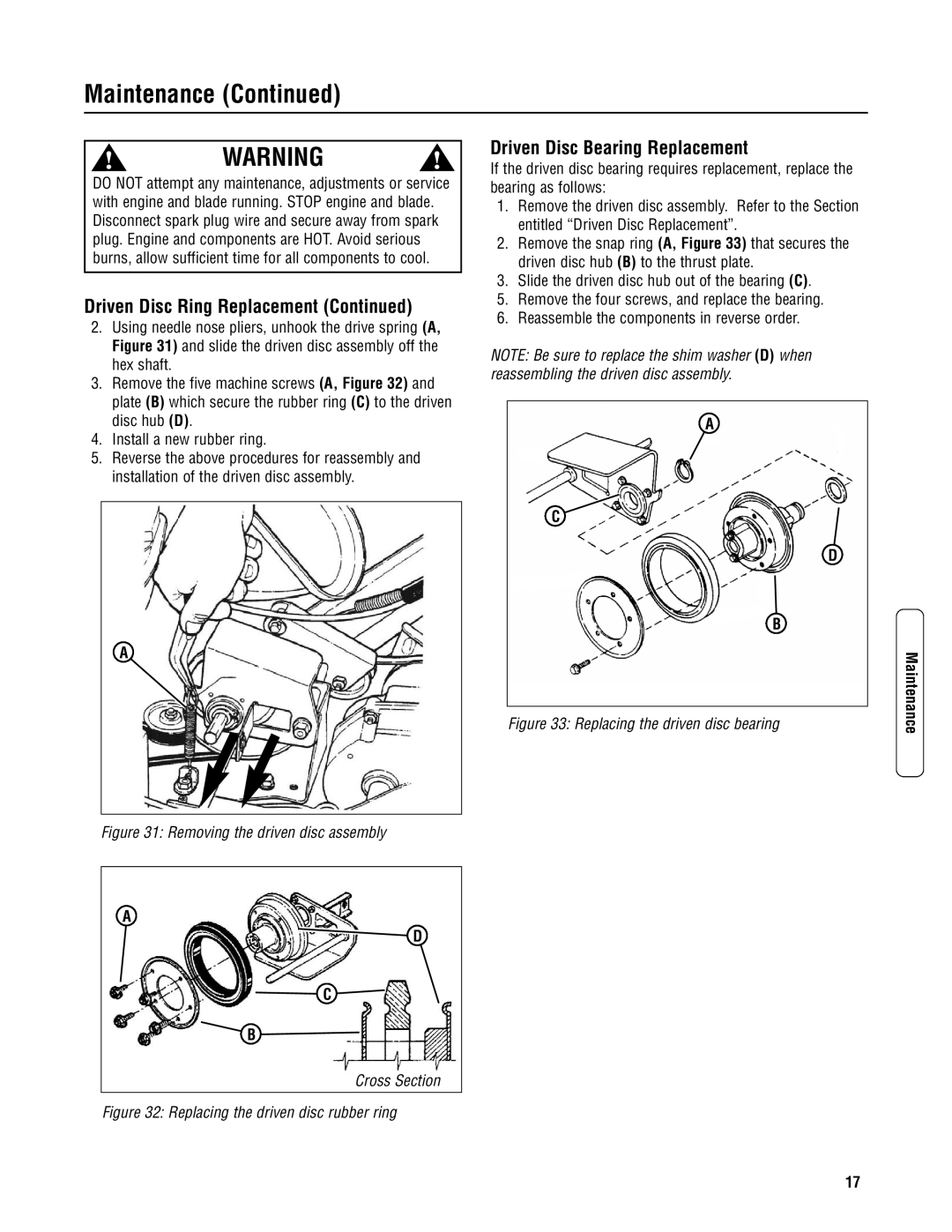

Driven Disc Bearing Replacement

If the driven disc bearing requires replacement, replace the bearing as follows:

1.Remove the driven disc assembly. Refer to the Section entitled “Driven Disc Replacement”.

2.Remove the snap ring (A, Figure 33) that secures the driven disc hub (B) to the thrust plate.

3.Slide the driven disc hub out of the bearing (C).

5.Remove the four screws, and replace the bearing.

6.Reassemble the components in reverse order.

NOTE: Be sure to replace the shim washer (D) when reassembling the driven disc assembly.

A |

C |

D |

B |

Maintenance

Figure 33: Replacing the driven disc bearing

Figure 31: Removing the driven disc assembly

A |

B |

D |

C |

Cross Section

Figure 32: Replacing the driven disc rubber ring

17