Maintenance (Continued)

! | WARNING | ! |

DO NOT attempt any maintenance, adjustments or service with engine and blade running. STOP engine and blade. Disconnect spark plug wire and secure away from spark plug. Engine and components are HOT. Avoid serious burns, allow sufficient time for all components to cool.

Driven Disc Adjustment (Continued)

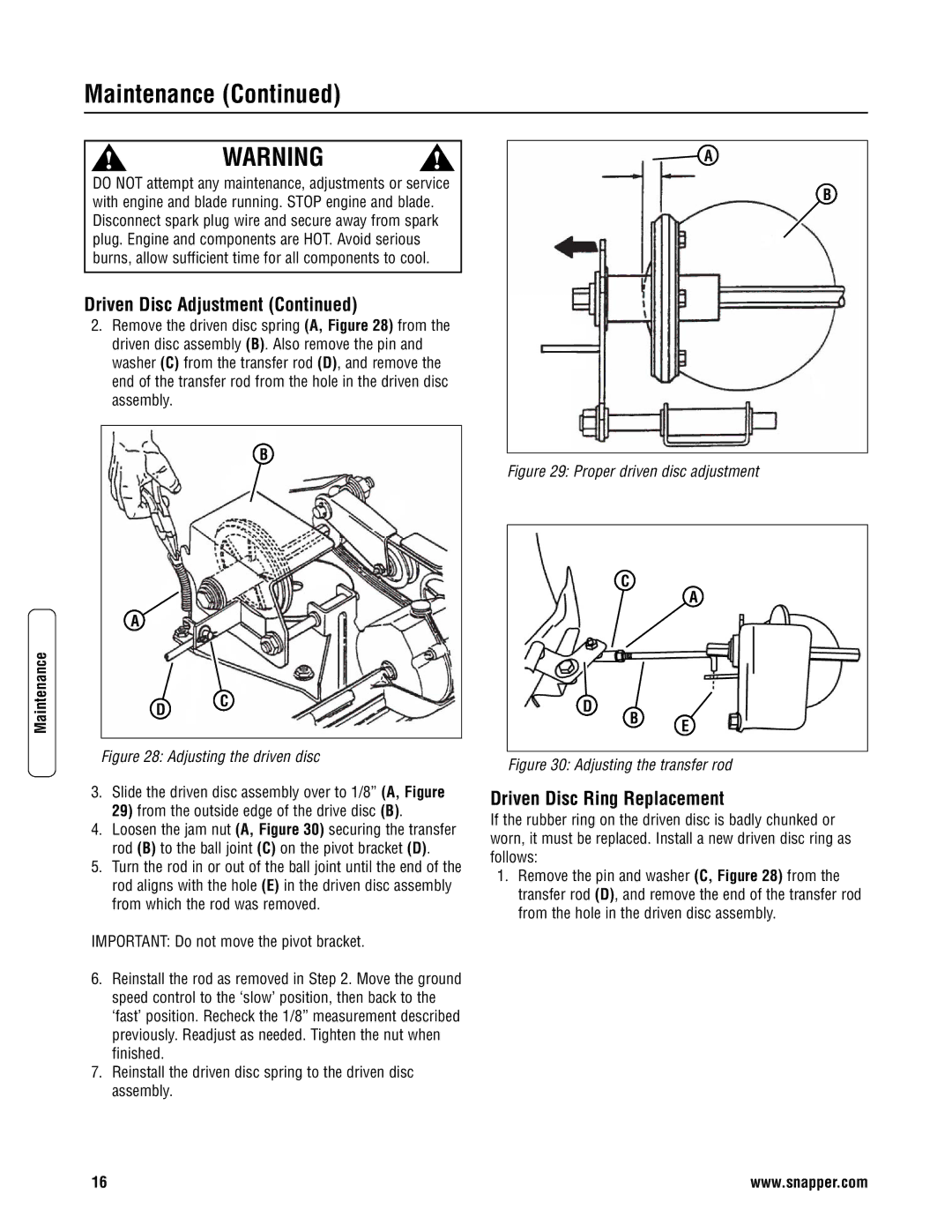

2.Remove the driven disc spring (A, Figure 28) from the driven disc assembly (B). Also remove the pin and washer (C) from the transfer rod (D), and remove the end of the transfer rod from the hole in the driven disc assembly.

A

B

Maintenance

A |

B |

D C

Figure 29: Proper driven disc adjustment

C

A

D

B E

Figure 28: Adjusting the driven disc

3.Slide the driven disc assembly over to 1/8” (A, Figure 29) from the outside edge of the drive disc (B).

4.Loosen the jam nut (A, Figure 30) securing the transfer rod (B) to the ball joint (C) on the pivot bracket (D).

5.Turn the rod in or out of the ball joint until the end of the rod aligns with the hole (E) in the driven disc assembly from which the rod was removed.

IMPORTANT: Do not move the pivot bracket.

6.Reinstall the rod as removed in Step 2. Move the ground speed control to the ‘slow’ position, then back to the ‘fast’ position. Recheck the 1/8” measurement described previously. Readjust as needed. Tighten the nut when finished.

7.Reinstall the driven disc spring to the driven disc assembly.

Figure 30: Adjusting the transfer rod

Driven Disc Ring Replacement

If the rubber ring on the driven disc is badly chunked or worn, it must be replaced. Install a new driven disc ring as follows:

1.Remove the pin and washer (C, Figure 28) from the transfer rod (D), and remove the end of the transfer rod from the hole in the driven disc assembly.

16 | www.snapper.com |