Maintenance

Maintenance (Continued)

! | WARNING | ! | 1. Visually check the engine drive belt for cracking, fraying, | ||||

severed or belt strands exposed. Replace the belt before | |||||||

DO NOT attempt any maintenance, adjustments or service | operating the mower. | ||||||

with engine and blade running. STOP engine and blade. | 2. Check for proper drive belt tension: | ||||||

Disconnect spark plug wire and secure away from spark | STOP the engine. | ||||||

plug. Engine and components are HOT. Avoid serious |

| Shift the ground speed control to 1st and engage | |||||

burns, allow sufficient time for all components to cool. |

| the wheel drive control. | |||||

Wear heavy leather gloves when handling or working |

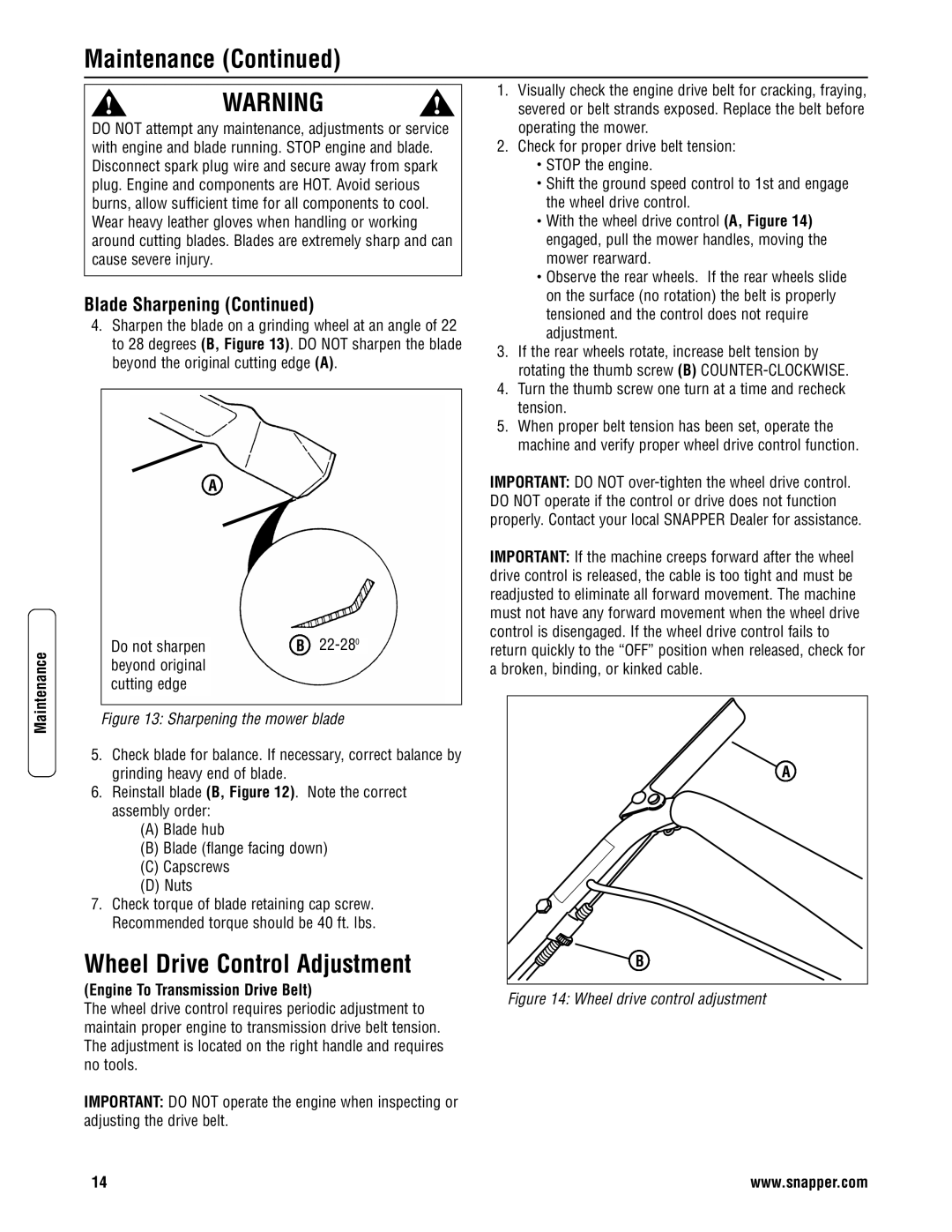

| With the wheel drive control (A, Figure 14) | |||||

around cutting blades. Blades are extremely sharp and can | engaged, pull the mower handles, moving the | ||||||

cause severe injury. |

|

|

|

| mower rearward. | ||

|

|

|

|

|

| Observe the rear wheels. If the rear wheels slide | |

|

|

|

|

|

| ||

Blade Sharpening (Continued) |

| on the surface (no rotation) the belt is properly | |||||

| tensioned and the control does not require | ||||||

4. Sharpen the blade on a grinding wheel at an angle of 22 | |||||||

adjustment. | |||||||

| to 28 degrees (B, Figure 13). DO NOT sharpen the blade | ||||||

| 3. If the rear wheels rotate, increase belt tension by | ||||||

| beyond the original cutting edge (A). |

| |||||

|

| rotating the thumb screw (B) | |||||

|

|

|

|

|

| ||

|

|

|

|

|

| 4. Turn the thumb screw one turn at a time and recheck | |

|

|

|

|

|

| ||

|

|

|

|

|

| tension. | |

|

|

|

|

|

| 5. When proper belt tension has been set, operate the | |

|

|

|

|

|

| machine and verify proper wheel drive control function. | |

| A |

|

|

|

| IMPORTANT: DO NOT | |

|

|

|

|

|

| DO NOT operate if the control or drive does not function | |

|

|

|

|

|

| properly. Contact your local SNAPPER Dealer for assistance. | |

|

|

|

|

|

| IMPORTANT: If the machine creeps forward after the wheel | |

|

|

|

|

|

| drive control is released, the cable is too tight and must be | |

|

|

|

|

|

| readjusted to eliminate all forward movement. The machine | |

|

|

|

|

|

| must not have any forward movement when the wheel drive | |

| Do not sharpen | B |

|

|

| control is disengaged. If the wheel drive control fails to | |

|

|

| return quickly to the “OFF” position when released, check for | ||||

|

|

| |||||

| beyond original |

|

|

|

| a broken, binding, or kinked cable. | |

| cutting edge |

|

|

|

|

| |

Figure 13: Sharpening the mower blade |

| |

5. Check blade for balance. If necessary, correct balance by | A | |

grinding heavy end of blade. | ||

6. Reinstall blade (B, Figure 12). Note the correct |

| |

assembly order: |

| |

(A) Blade hub |

| |

(B) Blade (flange facing down) |

| |

(C) Capscrews |

| |

(D) Nuts |

| |

7. Check torque of blade retaining cap screw. |

| |

Recommended torque should be 40 ft. lbs. |

| |

Wheel Drive Control Adjustment | B | |

(Engine To Transmission Drive Belt) | Figure 14: Wheel drive control adjustment | |

The wheel drive control requires periodic adjustment to | ||

| ||

maintain proper engine to transmission drive belt tension. |

| |

The adjustment is located on the right handle and requires |

| |

no tools. |

|

IMPORTANT: DO NOT operate the engine when inspecting or adjusting the drive belt.

14 | www.snapper.com |