SECTION 7 - MOWER ATTACHMENT SERVICE

7.5 MOWER SPINDLES (Field Serviceable Spindles) BEARING REPLACEMENT

In the event that a spindle bearing requires replacement, the SNAPPER Field Serviceable Spindles have been designed so that no special tools or presses are required.

IMPORTANT: Spindle housing must be filled with grease before operating mower. Failure to fill housing will cause premature bearing failure.

1.Remove belt. Loosen blade nut and remove. Allow blade bolt, washer, blade and four spacers to drop down out of the spindle housing. See Figure 7.7.

REMOVE NUT

![]() REMOVE BELT

REMOVE BELT

FROM SPINDLE

REMOVE BLADE

BOLT

FIGURE 7.7

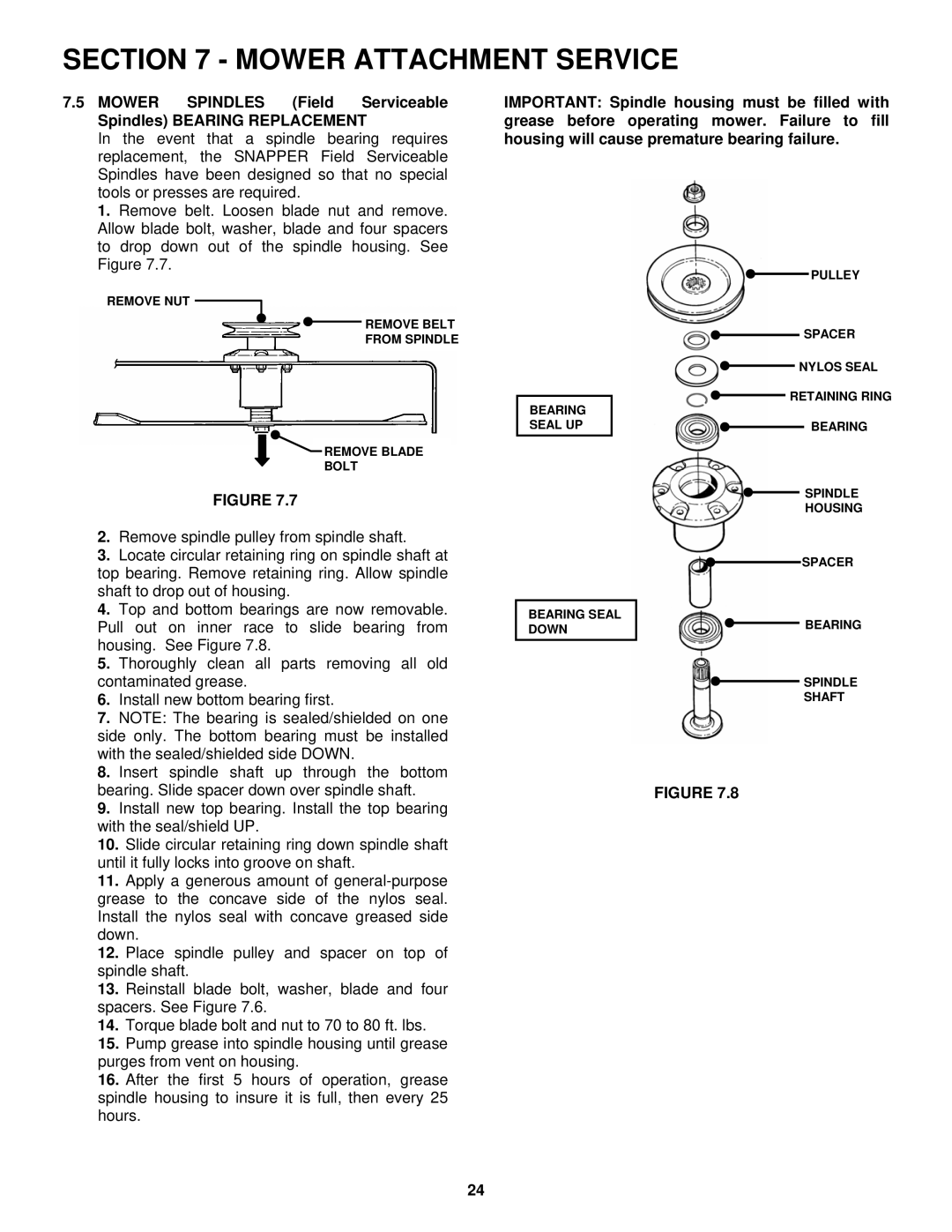

2. | Remove spindle pulley from spindle shaft. |

3. | Locate circular retaining ring on spindle shaft at |

top bearing. Remove retaining ring. Allow spindle | |

shaft to drop out of housing. | |

4. | Top and bottom bearings are now removable. |

Pull out on inner race to slide bearing from | |

housing. See Figure 7.8. | |

5. | Thoroughly clean all parts removing all old |

contaminated grease. | |

6. | Install new bottom bearing first. |

7. | NOTE: The bearing is sealed/shielded on one |

side only. The bottom bearing must be installed | |

with the sealed/shielded side DOWN. | |

8. | Insert spindle shaft up through the bottom |

BEARING

SEAL UP

BEARING SEAL DOWN

![]() PULLEY

PULLEY

![]() SPACER

SPACER

![]() NYLOS SEAL

NYLOS SEAL

![]() RETAINING RING

RETAINING RING

![]() BEARING

BEARING

![]() SPINDLE

SPINDLE

HOUSING

![]() SPACER

SPACER

![]() BEARING

BEARING

![]() SPINDLE SHAFT

SPINDLE SHAFT

bearing. Slide spacer down over spindle shaft. | |

9. Install new top bearing. Install the top bearing | |

with the seal/shield UP. | |

10. | Slide circular retaining ring down spindle shaft |

until it fully locks into groove on shaft. | |

11. | Apply a generous amount of |

grease to the concave side of the nylos seal. | |

Install the nylos seal with concave greased side | |

down. | |

12. | Place spindle pulley and spacer on top of |

spindle shaft. | |

13. | Reinstall blade bolt, washer, blade and four |

spacers. See Figure 7.6. | |

14. | Torque blade bolt and nut to 70 to 80 ft. lbs. |

15. | Pump grease into spindle housing until grease |

purges from vent on housing. | |

16. | After the first 5 hours of operation, grease |

spindle housing to insure it is full, then every 25 | |

hours. | |

FIGURE 7.8

24