Section 4 - REPAIR & ADJUSTMENTS

WARNING

Before attempting any adjustments or repairs, STOP the engine, remove the spark plug wire from the spark plug and secure wire away from plug.

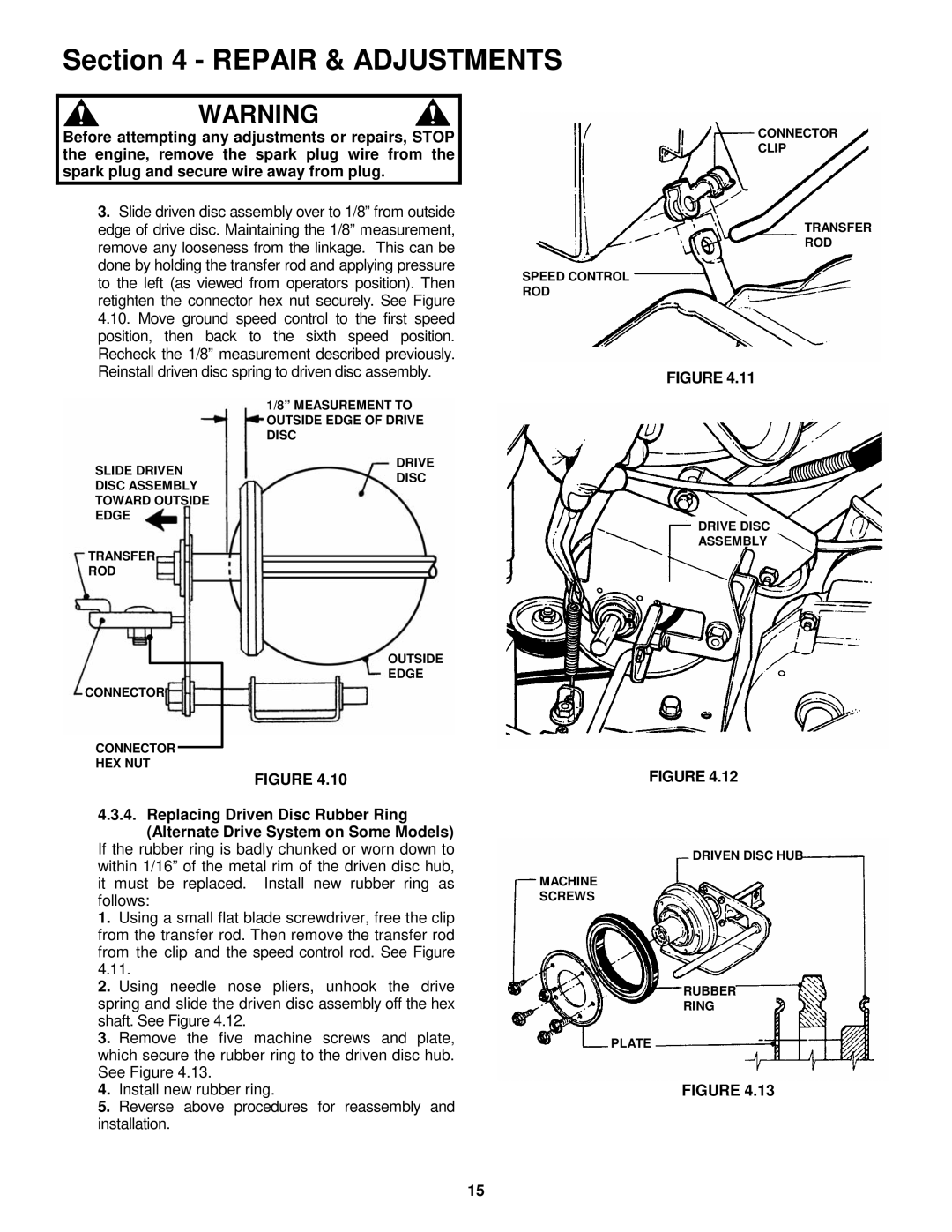

3.Slide driven disc assembly over to 1/8” from outside edge of drive disc. Maintaining the 1/8” measurement, remove any looseness from the linkage. This can be done by holding the transfer rod and applying pressure to the left (as viewed from operators position). Then retighten the connector hex nut securely. See Figure

4.10.Move ground speed control to the first speed position, then back to the sixth speed position. Recheck the 1/8” measurement described previously. Reinstall driven disc spring to driven disc assembly.

1/8” MEASUREMENT TO OUTSIDE EDGE OF DRIVE DISC

CONNECTOR

CLIP

TRANSFER

ROD

SPEED CONTROL

ROD

FIGURE 4.11

SLIDE DRIVEN

DRIVE DISC

DISC ASSEMBLY

TOWARD OUTSIDE

EDGE

TRANSFER

ROD

OUTSIDE

EDGE

CONNECTOR

CONNECTOR

HEX NUT

FIGURE 4.10

4.3.4.Replacing Driven Disc Rubber Ring (Alternate Drive System on Some Models)

If the rubber ring is badly chunked or worn down to within 1/16” of the metal rim of the driven disc hub, it must be replaced. Install new rubber ring as follows:

1.Using a small flat blade screwdriver, free the clip from the transfer rod. Then remove the transfer rod from the clip and the speed control rod. See Figure

2.Using needle nose pliers, unhook the drive spring and slide the driven disc assembly off the hex shaft. See Figure 4.12.

3.Remove the five machine screws and plate, which secure the rubber ring to the driven disc hub. See Figure 4.13.

4.Install new rubber ring.

5.Reverse above procedures for reassembly and installation.

DRIVE DISC

ASSEMBLY

FIGURE 4.12

DRIVEN DISC HUB

MACHINE

SCREWS

RUBBER

RING

PLATE

FIGURE 4.13

15