|

| 2.0 |

|

| μm |

3.0 μm | ||

|

|

|

4.0μm

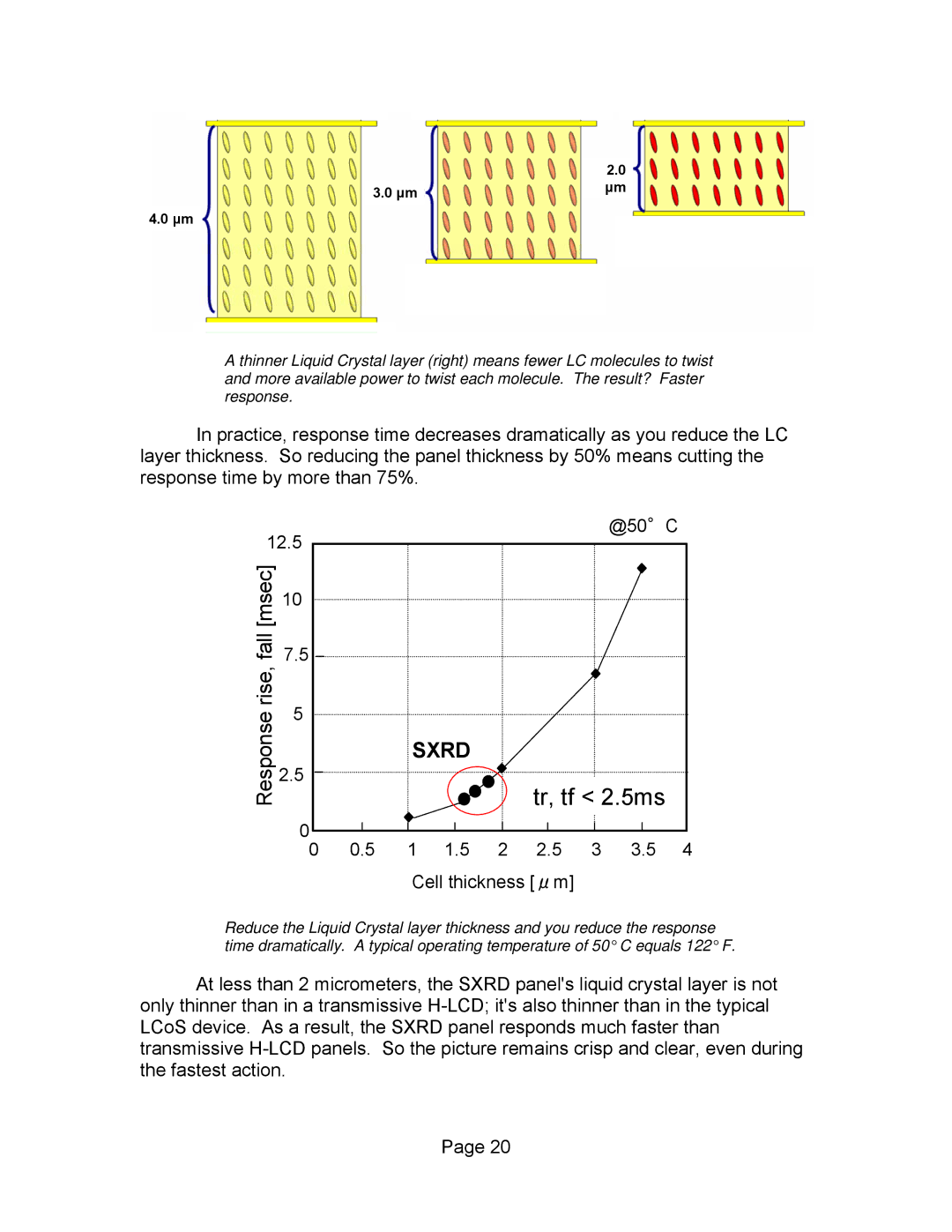

A thinner Liquid Crystal layer (right) means fewer LC molecules to twist and more available power to twist each molecule. The result? Faster response.

In practice, response time decreases dramatically as you reduce the LC layer thickness. So reducing the panel thickness by 50% means cutting the response time by more than 75%.

12.5

@50°C

[msec]fall | 10 |

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| |

rise, | 7.5 |

|

|

|

|

|

|

|

|

5 |

|

|

|

|

|

|

|

| |

Response |

|

|

|

| tr, tf < 2.5ms |

| |||

2.5 |

| SXRD |

|

| |||||

|

|

|

|

|

|

| |||

|

|

|

|

|

|

|

|

| |

| 0 | 0.5 | 1 | 1.5 | 2 | 2.5 | 3 | 3.5 | 4 |

| 0 | ||||||||

Cell thickness [μm]

Reduce the Liquid Crystal layer thickness and you reduce the response time dramatically. A typical operating temperature of 50° C equals 122° F.

At less than 2 micrometers, the SXRD panel's liquid crystal layer is not only thinner than in a transmissive

Page 20