SECTION 5

MECHANICAL ADJUSTMENTS

1. Clean the following parts with a

swab: |

|

playback head | pinch roller |

rubber belt | capstan |

idler |

|

2.Demagnetize the playback head with a head demagnetizer.

3.Do not use a magnetized screwdriver for the adjustments.

4.The adjustments should be performed with the power supply voltage (14.4 V) unless otherwise noted.

• Torque Measurement

XR-M510

SECTION 6

ELECTRICAL ADJUSTMENTS

TEST MODE

<Set the Test Mode>

1.Turn ON the regulated power supply. (All LEDs on the set lights up, and the clock is displayed.)

Note: Press the [OFF] button, if the clock is not displayed.

2.Push the preset [4] button.

3.Push the preset [5] button.

4.Press the preset [1] button for more than two seconds.

5.Then the display indicates all lights, the test mode is set.

Mode | Torque Meter | Meter Reading | |

|

| 2.95 – 6.73 mN•m | |

Forward | 30 – 65 g•cm | ||

|

| (0.42 – 0.90 oz•inch) | |

Forward |

| 0.05 – 0.44mN•m | |

0.5 – 4.5 g•cm | |||

Back Tension | |||

| (0.01 | ||

|

| ||

|

| 2.95 – 6.73 mN•m | |

Reverse | (25 – 55 g•cm) |

<Release the Test mode>

1. Push the [OFF] button.

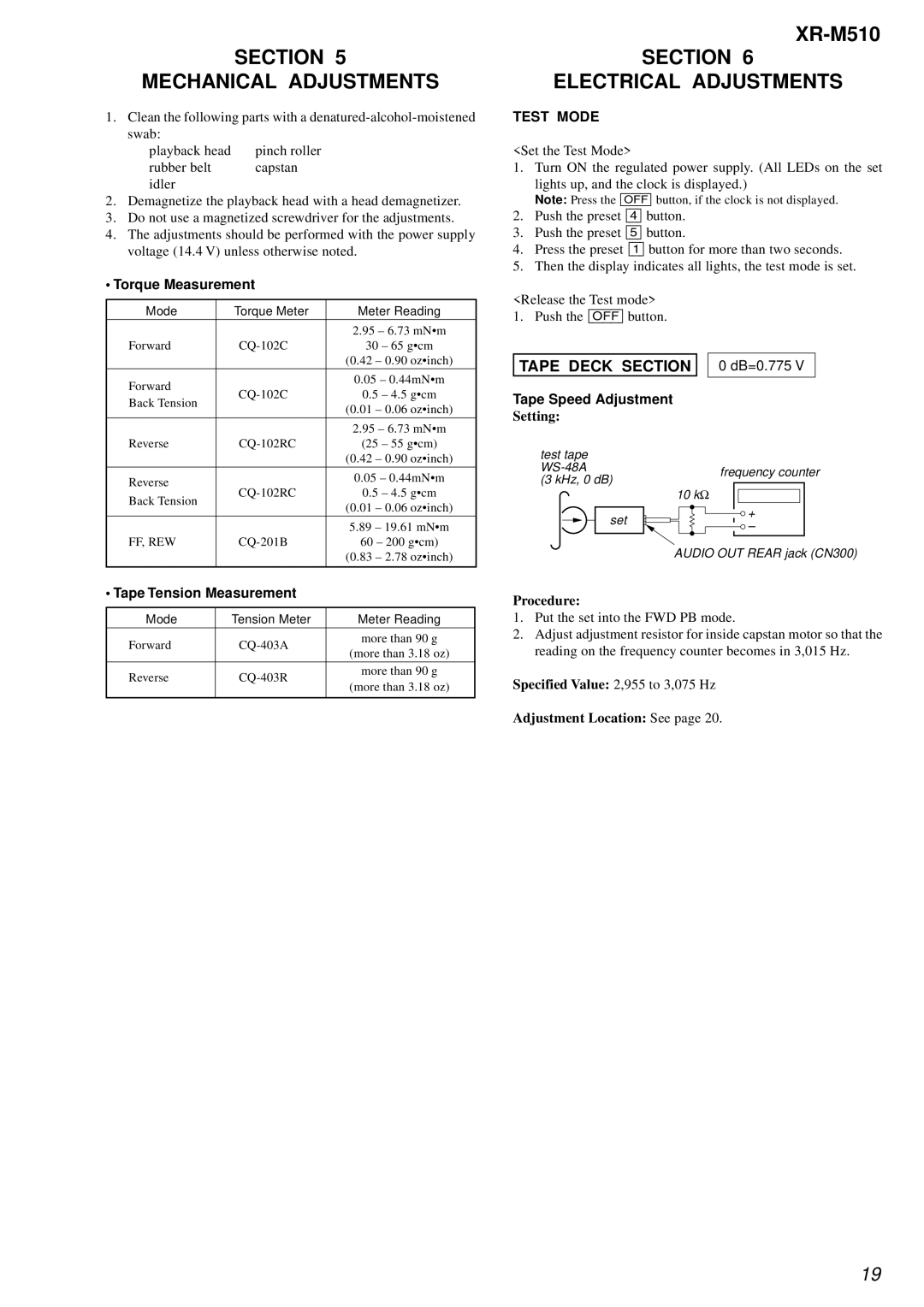

TAPE DECK SECTION

Tape Speed Adjustment

Setting:

0 dB=0.775 V

|

| (0.42 | – 0.90 oz•inch) | |

Reverse |

| 0.05 – 0.44mN•m | ||

0.5 – 4.5 g•cm | ||||

Back Tension | ||||

| (0.01 | |||

|

| |||

|

| 5.89 – 19.61 mN•m | ||

FF, REW | 60 – 200 g•cm) | |||

|

| (0.83 | – 2.78 oz•inch) | |

• Tape Tension Measurement

Mode | Tension Meter | Meter Reading | |

Forward | more than 90 g | ||

(more than 3.18 oz) | |||

|

| ||

|

|

| |

Reverse | more than 90 g | ||

(more than 3.18 oz) | |||

|

| ||

|

|

|

test tape

10 kΩ

+

set–

AUDIO OUT REAR jack (CN300)

Procedure:

1.Put the set into the FWD PB mode.

2.Adjust adjustment resistor for inside capstan motor so that the reading on the frequency counter becomes in 3,015 Hz.

Specified Value: 2,955 to 3,075 Hz

Adjustment Location: See page 20.

19