Model SB1263 | I N S T R U C T I O N S | Mfg. Since 9/11 |

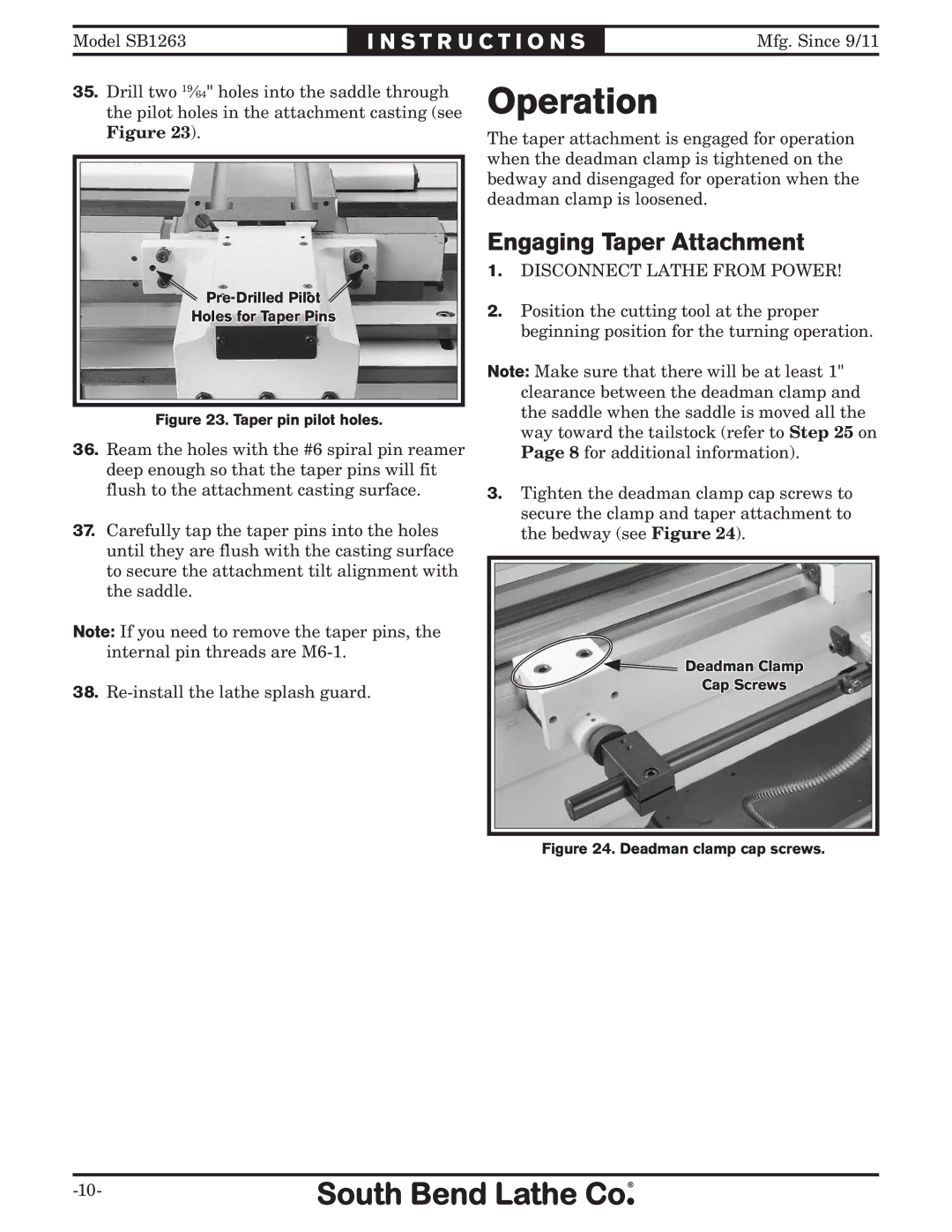

35.Drill two 19⁄64" holes into the saddle through the pilot holes in the attachment casting (see Figure 23).

![]()

![]()

Holes for Taper Pins

Figure 23. Taper pin pilot holes.

36.Ream the holes with the #6 spiral pin reamer deep enough so that the taper pins will fit flush to the attachment casting surface.

37.Carefully tap the taper pins into the holes until they are flush with the casting surface to secure the attachment tilt alignment with the saddle.

Note: If you need to remove the taper pins, the internal pin threads are

38.

Operation

The taper attachment is engaged for operation when the deadman clamp is tightened on the bedway and disengaged for operation when the deadman clamp is loosened.

Engaging Taper Attachment

1.DISCONNECT LATHE FROM POWER!

2.Position the cutting tool at the proper beginning position for the turning operation.

Note: Make sure that there will be at least 1" clearance between the deadman clamp and the saddle when the saddle is moved all the way toward the tailstock (refer to Step 25 on Page 8 for additional information).

3.Tighten the deadman clamp cap screws to secure the clamp and taper attachment to the bedway (see Figure 24).

![]() Deadman Clamp

Deadman Clamp

Cap Screws