Marley / MC Fluid Cooler / Specifications: Base

Specifications | Specification Value |

17

the test and will make such corrections as are appropriate and agreeable to the owner to compensate for the perfor- mance deficiency.

4.0Coil:

4.1Coil(s) shall consist of fully welded box headers with serpentine coils and

5.0Design Loading:

5.1The fluid cooler and its components shall be designed to withstand a wind load of 1.44 kPa. The fluid cooler shall be designed to withstand shipping and hoisting loads of 2g horizontal or 3g vertical. Handrails, where specified shall be capable of withstanding a 890

N concentrated live load in any direc- tion and shall be designed in accor- dance with OSHA guidelines.

6.0Construction:

6.1Except where otherwise specified, all components of the fluid cooler shall be fabricated of

6.2The specifications, as written, are intended to indicate those materials that will be capable of withstanding the above water quality in continuing service, as well as the loads described in paragraph 4.1. They are to be regarded as minimum requirements. Where component materials unique to individual fluid cooler designs are not specified, the manufacturers shall

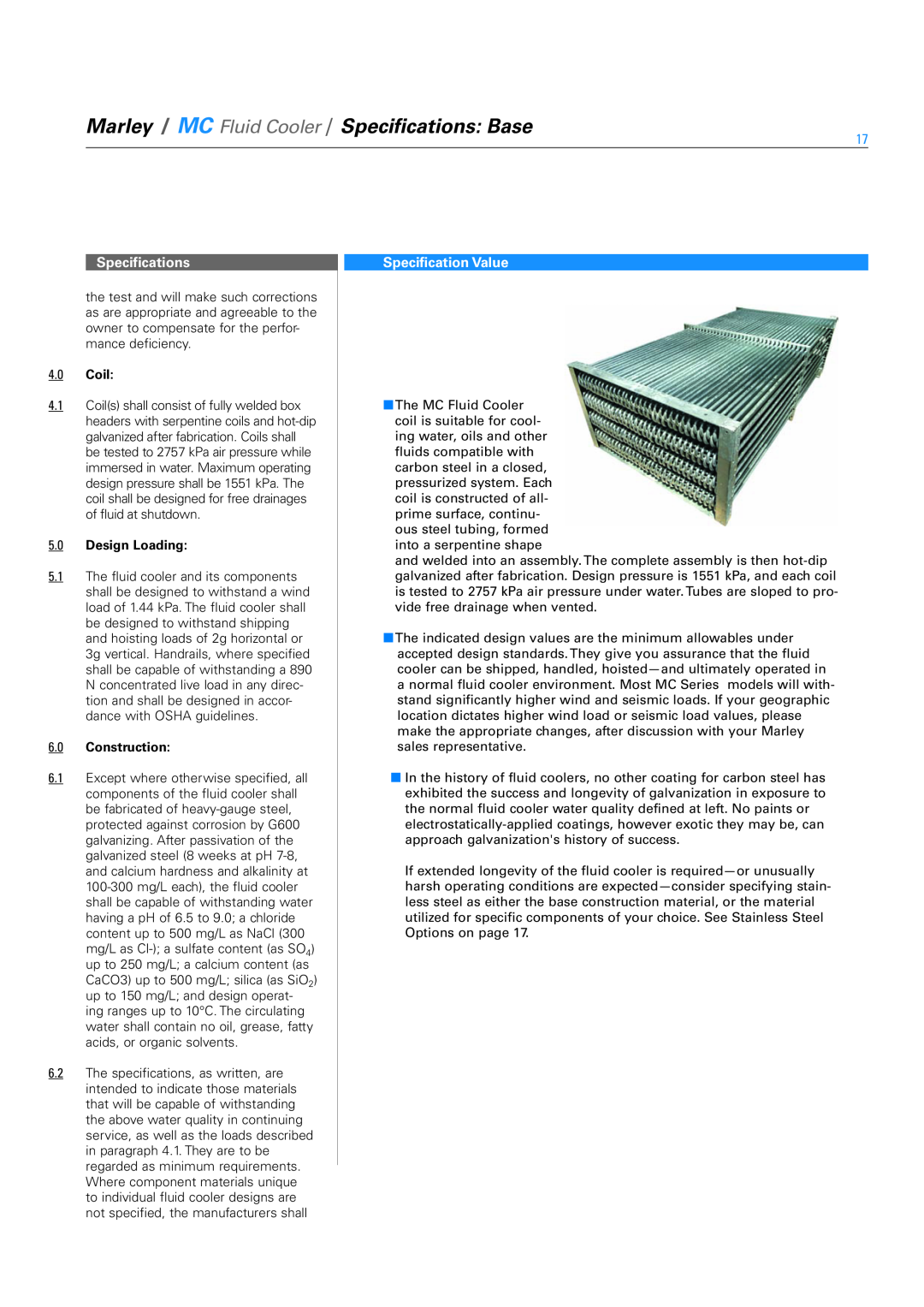

■The MC Fluid Cooler coil is suitable for cool- ing water, oils and other fluids compatible with carbon steel in a closed, pressurized system. Each coil is constructed of all- prime surface, continu- ous steel tubing, formed into a serpentine shape

and welded into an assembly. The complete assembly is then

■The indicated design values are the minimum allowables under accepted design standards. They give you assurance that the fluid cooler can be shipped, handled,

■■ In the history of fluid coolers, no other coating for carbon steel has exhibited the success and longevity of galvanization in exposure to the normal fluid cooler water quality defined at left. No paints or

If extended longevity of the fluid cooler is