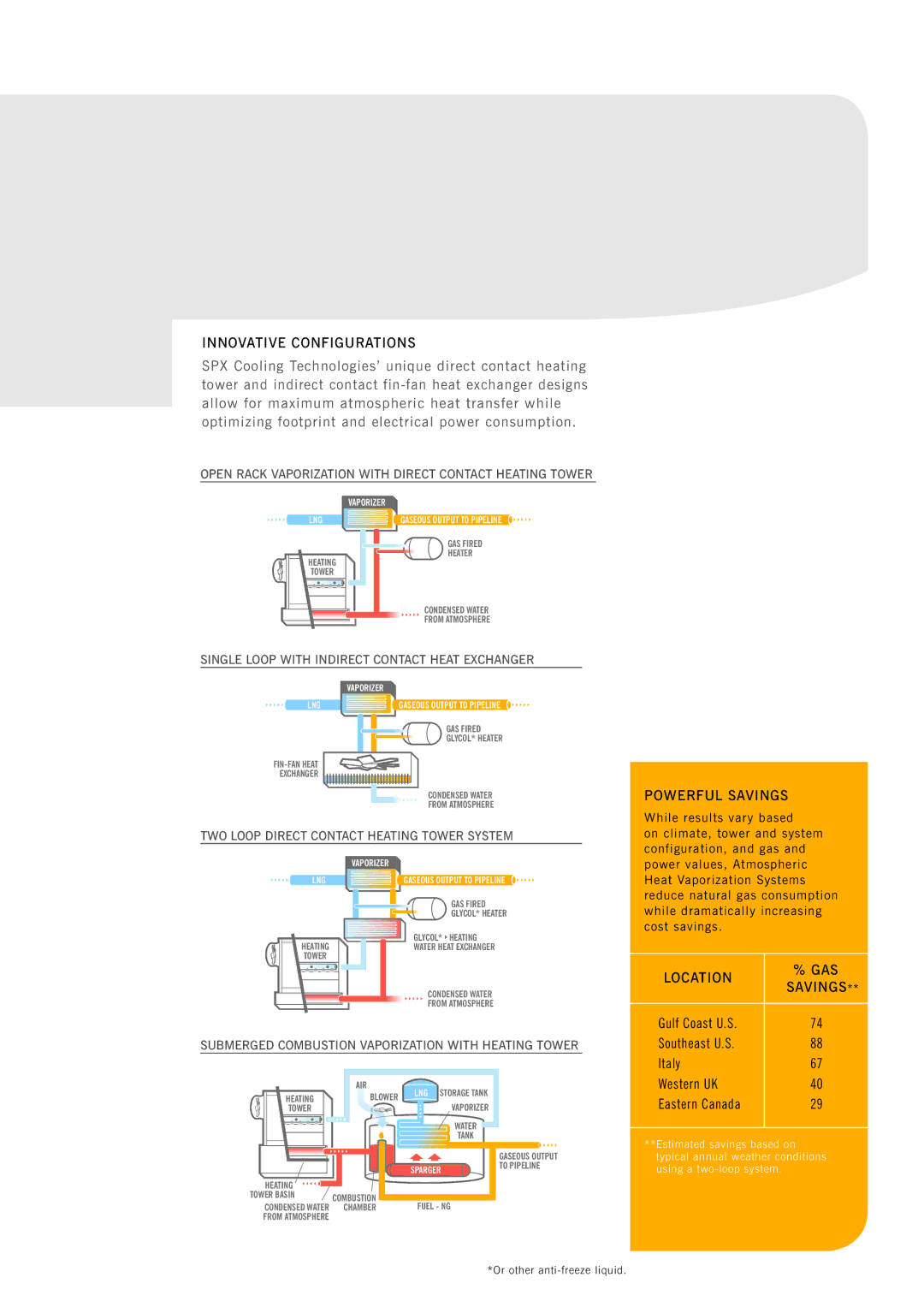

INNOVATIVE CONFIGURATIONS

SPX Cooling Technologies’ unique direct contact heating tower and indirect contact

OPEN RACK VAPORIZATION WITH DIRECT CONTACT HEATING TOWER

VAPORIZER

LNG | GASEOUS OUTPUT TO PIPELINE |

GAS FIRED

HEATER

HEATING

TOWER

CONDENSED WATER

FROM ATMOSPHERE

SINGLE LOOP WITH INDIRECT CONTACT HEAT EXCHANGER

VAPORIZER

LNG | GASEOUS OUTPUT TO PIPELINE |

GAS FIRED

GLYCOL* HEATER

EXCHANGER

CONDENSED WATER

FROM ATMOSPHERE

TWO LOOP DIRECT CONTACT HEATING TOWER SYSTEM

VAPORIZER

LNG | GASEOUS OUTPUT TO PIPELINE |

GAS FIRED

GLYCOL* HEATER

HEATING | GLYCOL* HEATING |

WATER HEAT EXCHANGER | |

TOWER |

|

| CONDENSED WATER |

| FROM ATMOSPHERE |

SUBMERGED COMBUSTION VAPORIZATION WITH HEATING TOWER

POWERFUL SAVINGS

While results vary based

on climate, tower and system configuration, and gas and power values, Atmospheric Heat Vaporization Systems reduce natural gas consumption while dramatically increasing cost savings.

LOCATION | % GAS | |

SAVINGS** | ||

| ||

Gulf Coast U.S. | 74 | |

Southeast U.S. | 88 | |

Italy | 67 |

| AIR | LNG | STORAGE TANK | |

HEATING | BLOWER | |||

| VAPORIZER | |||

TOWER |

|

| ||

|

|

| WATER | |

|

|

| TANK | |

|

| SPARGER | ||

HEATING |

|

|

| |

TOWER BASIN | COMBUSTION | FUEL - NG | ||

CONDENSED WATER | CHAMBER | |||

FROM ATMOSPHERE |

|

|

| |

GASEOUS OUTPUT TO PIPELINE

Western UK | 40 |

Eastern Canada | 29 |

**Estimated savings based on typical annual weather conditions using a

*Or other