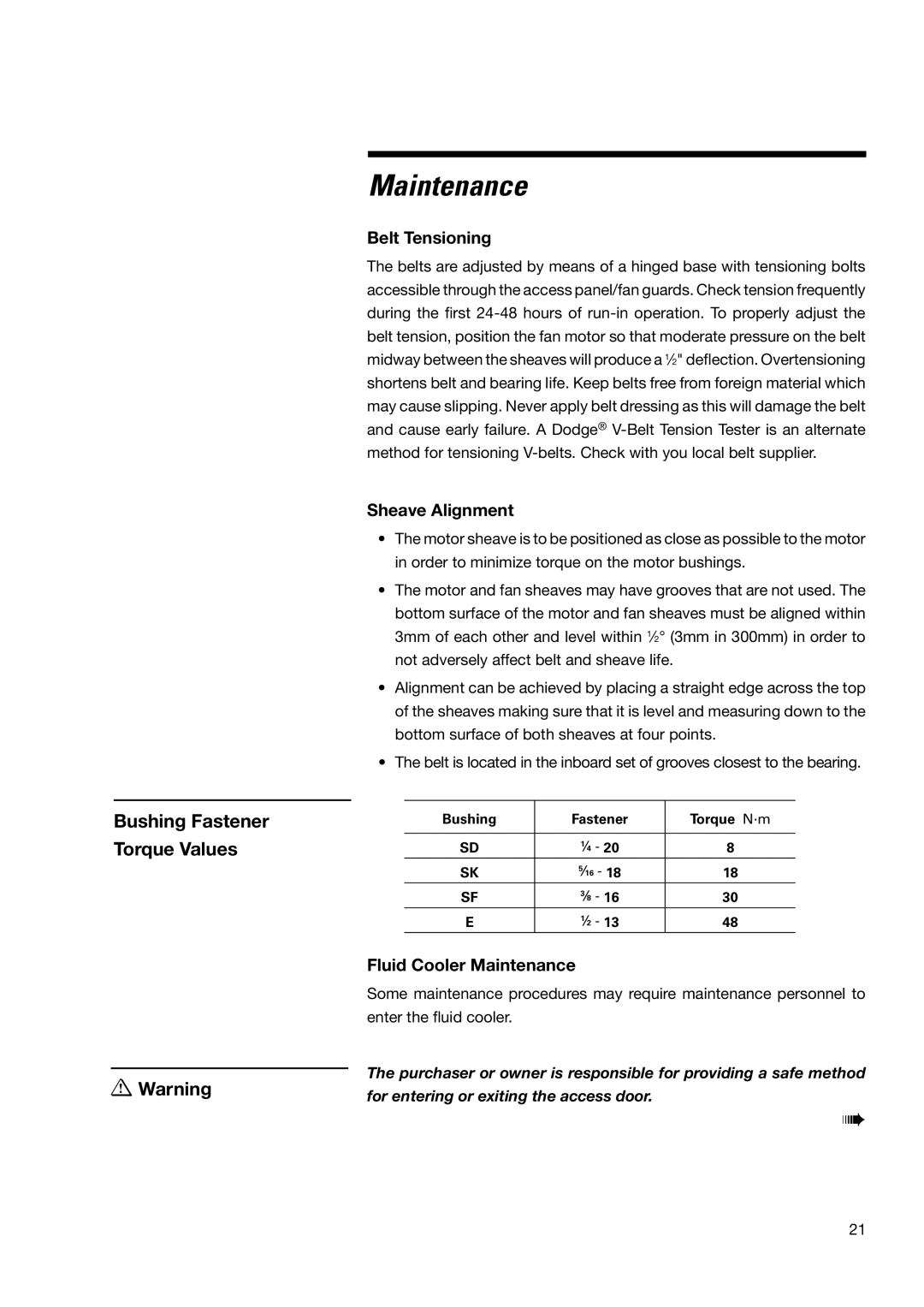

Bushing Fastener Torque Values

![]() Warning

Warning

Maintenance

Belt Tensioning

The belts are adjusted by means of a hinged base with tensioning bolts accessible through the access panel/fan guards. Check tension frequently during the first

Sheave Alignment

•The motor sheave is to be positioned as close as possible to the motor in order to minimize torque on the motor bushings.

•The motor and fan sheaves may have grooves that are not used. The bottom surface of the motor and fan sheaves must be aligned within 3mm of each other and level within 1⁄2° (3mm in 300mm) in order to not adversely affect belt and sheave life.

•Alignment can be achieved by placing a straight edge across the top of the sheaves making sure that it is level and measuring down to the bottom surface of both sheaves at four points.

•The belt is located in the inboard set of grooves closest to the bearing.

Bushing | Fastener | Torque N·m | |

|

|

|

|

SD | 1⁄4 | - 20 | 8 |

SK | 5⁄16 - 18 | 18 | |

SF | 3⁄8 | - 16 | 30 |

E | 1⁄2 | - 13 | 48 |

Fluid Cooler Maintenance

Some maintenance procedures may require maintenance personnel to enter the fluid cooler.

The purchaser or owner is responsible for providing a safe method

for entering or exiting the access door.

➠

21