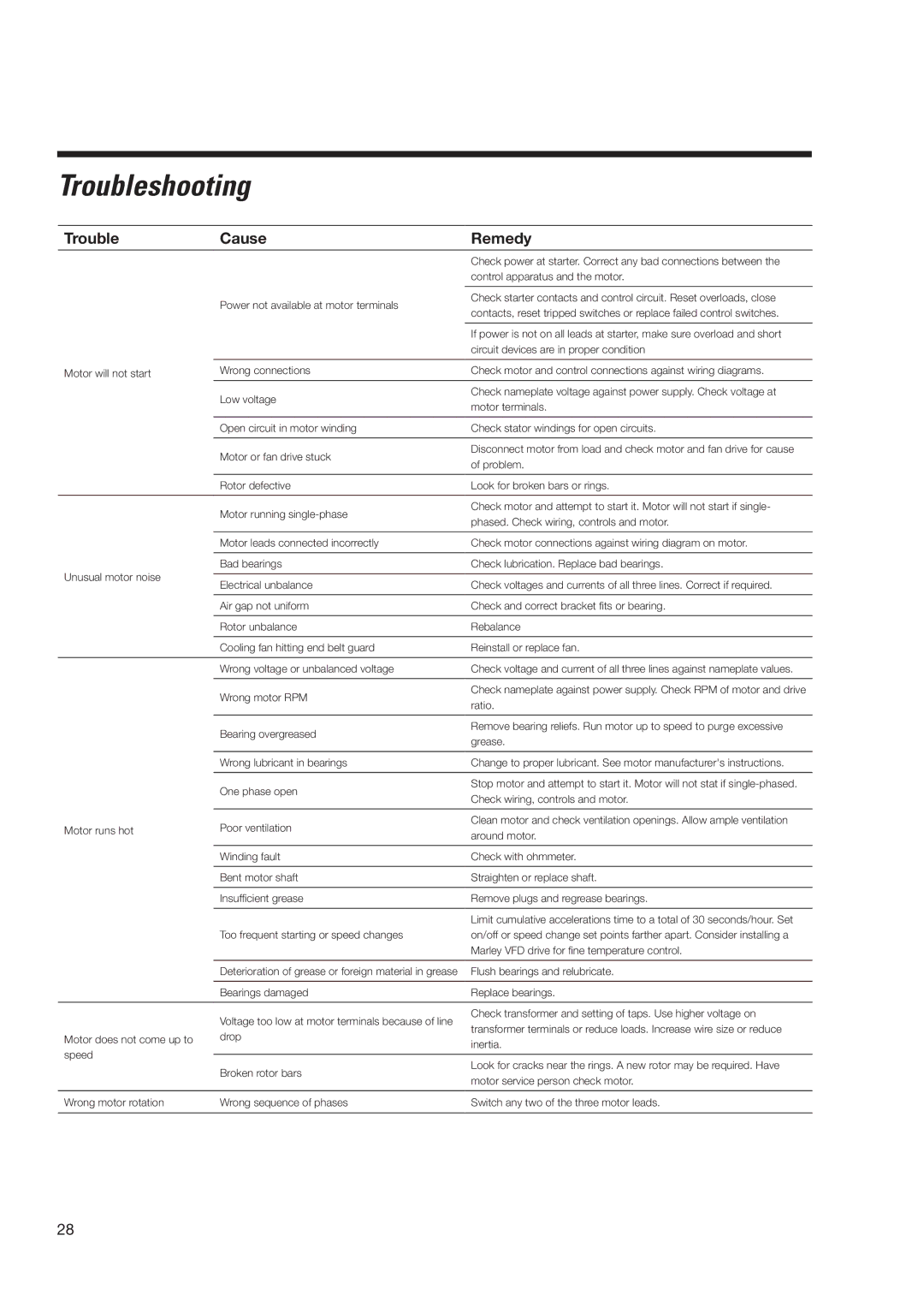

Troubleshooting

Trouble | Cause | Remedy | |

|

|

| |

|

| Check power at starter. Correct any bad connections between the | |

|

| control apparatus and the motor. | |

|

|

| |

| Power not available at motor terminals | Check starter contacts and control circuit. Reset overloads, close | |

| contacts, reset tripped switches or replace failed control switches. | ||

|

| ||

|

|

| |

|

| If power is not on all leads at starter, make sure overload and short | |

|

| circuit devices are in proper condition | |

|

|

| |

Motor will not start | Wrong connections | Check motor and control connections against wiring diagrams. | |

| Low voltage | Check nameplate voltage against power supply. Check voltage at | |

| motor terminals. | ||

|

| ||

|

|

| |

| Open circuit in motor winding | Check stator windings for open circuits. | |

|

|

| |

| Motor or fan drive stuck | Disconnect motor from load and check motor and fan drive for cause | |

| of problem. | ||

|

| ||

|

|

| |

| Rotor defective | Look for broken bars or rings. | |

|

|

| |

| Motor running | Check motor and attempt to start it. Motor will not start if single- | |

| phased. Check wiring, controls and motor. | ||

|

| ||

|

|

| |

| Motor leads connected incorrectly | Check motor connections against wiring diagram on motor. | |

|

|

| |

| Bad bearings | Check lubrication. Replace bad bearings. | |

Unusual motor noise |

|

| |

Electrical unbalance | Check voltages and currents of all three lines. Correct if required. | ||

| |||

|

|

| |

| Air gap not uniform | Check and correct bracket fits or bearing. | |

|

|

| |

| Rotor unbalance | Rebalance | |

|

|

| |

| Cooling fan hitting end belt guard | Reinstall or replace fan. | |

|

|

| |

| Wrong voltage or unbalanced voltage | Check voltage and current of all three lines against nameplate values. | |

|

|

| |

| Wrong motor RPM | Check nameplate against power supply. Check RPM of motor and drive | |

| ratio. | ||

|

| ||

|

|

| |

| Bearing overgreased | Remove bearing reliefs. Run motor up to speed to purge excessive | |

| grease. | ||

|

| ||

|

|

| |

| Wrong lubricant in bearings | Change to proper lubricant. See motor manufacturer's instructions. | |

|

|

| |

| One phase open | Stop motor and attempt to start it. Motor will not stat if | |

| Check wiring, controls and motor. | ||

|

| ||

|

|

| |

Motor runs hot | Poor ventilation | Clean motor and check ventilation openings. Allow ample ventilation | |

around motor. | |||

|

| ||

|

|

| |

| Winding fault | Check with ohmmeter. | |

|

|

| |

| Bent motor shaft | Straighten or replace shaft. | |

|

|

| |

| Insufficient grease | Remove plugs and regrease bearings. | |

|

|

| |

|

| Limit cumulative accelerations time to a total of 30 seconds/hour. Set | |

| Too frequent starting or speed changes | on/off or speed change set points farther apart. Consider installing a | |

|

| Marley VFD drive for fine temperature control. | |

|

|

| |

| Deterioration of grease or foreign material in grease | Flush bearings and relubricate. | |

|

|

| |

| Bearings damaged | Replace bearings. | |

|

|

| |

| Voltage too low at motor terminals because of line | Check transformer and setting of taps. Use higher voltage on | |

| transformer terminals or reduce loads. Increase wire size or reduce | ||

Motor does not come up to | drop | ||

inertia. | |||

speed |

| ||

|

| ||

Broken rotor bars | Look for cracks near the rings. A new rotor may be required. Have | ||

| |||

| motor service person check motor. | ||

|

| ||

|

|

| |

Wrong motor rotation | Wrong sequence of phases | Switch any two of the three motor leads. | |

|

|

|

28