PRE-OPERATION

PREPARATION FOR USE

Do not operate the power unit until you have read the engine operating and maintenance instructions manual furnished with the unit.

1. ENGINE CRANKCASE OIL LEVEL

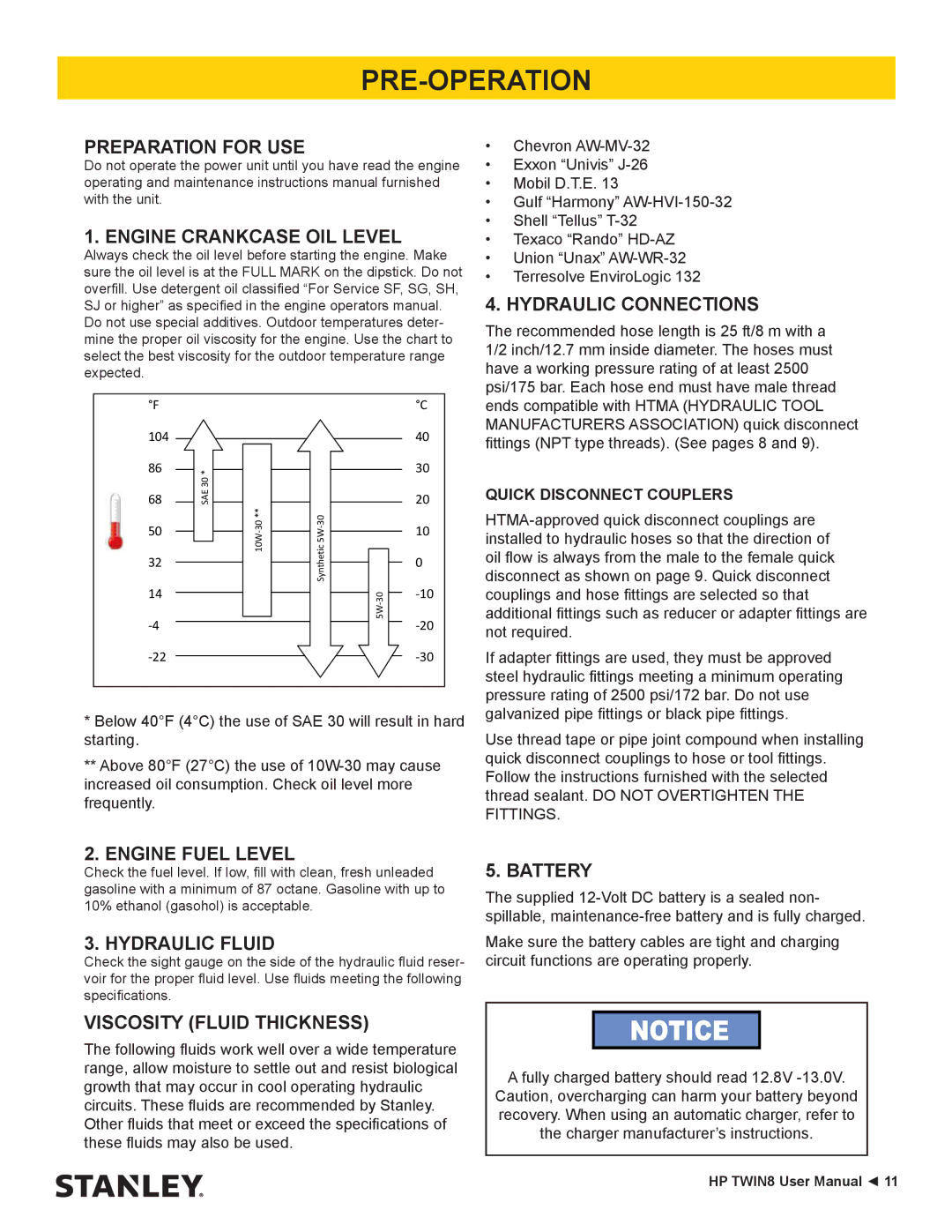

Always check the oil level before starting the engine. Make sure the oil level is at the FULL MARK on the dipstick. Do not overfill. Use detergent oil classified “For Service SF, SG, SH, SJ or higher” as specified in the engine operators manual. Do not use special additives. Outdoor temperatures deter- mine the proper oil viscosity for the engine. Use the chart to select the best viscosity for the outdoor temperature range expected.

•Chevron

•Exxon “Univis”

•Mobil D.T.E. 13

•Gulf “Harmony”

•Shell “Tellus”

•Texaco “Rando”

•Union “Unax”

•Terresolve EnviroLogic 132

4. HYDRAULIC CONNECTIONS

The recommended hose length is 25 ft/8 m with a 1/2 inch/12.7 mm inside diameter. The hoses must have a working pressure rating of at least 2500 psi/175 bar. Each hose end must have male thread

°F |

|

104 |

|

86 |

|

* | |

68 | SAE30 |

|

50

32

14

Synthetic

°C

40

30

20

10

0

ends compatible with HTMA (HYDRAULIC TOOL MANUFACTURERS ASSOCIATION) quick disconnect fittings (NPT type threads). (See pages 8 and 9).

QUICK DISCONNECT COUPLERS

If adapter fittings are used, they must be approved steel hydraulic fittings meeting a minimum operating pressure rating of 2500 psi/172 bar. Do not use

*Below 40°F (4°C) the use of SAE 30 will result in hard starting.

**Above 80°F (27°C) the use of

galvanized pipe fittings or black pipe fittings.

Use thread tape or pipe joint compound when installing quick disconnect couplings to hose or tool fittings. Follow the instructions furnished with the selected thread sealant. DO NOT OVERTIGHTEN THE FITTINGS.

2. ENGINE FUEL LEVEL

Check the fuel level. If low, fill with clean, fresh unleaded gasoline with a minimum of 87 octane. Gasoline with up to 10% ethanol (gasohol) is acceptable.

3. HYDRAULIC FLUID

Check the sight gauge on the side of the hydraulic fluid reser- voir for the proper fluid level. Use fluids meeting the following specifications.

VISCOSITY (FLUID THICKNESS)

The following fluids work well over a wide temperature range, allow moisture to settle out and resist biological growth that may occur in cool operating hydraulic circuits. These fluids are recommended by Stanley. Other fluids that meet or exceed the specifications of these fluids may also be used.

5. BATTERY

The supplied

Make sure the battery cables are tight and charging circuit functions are operating properly.

NOTICE

A fully charged battery should read 12.8V

HP TWIN8 User Manual ◄ 11