| GABLE VENT | |

| TO OUTDOORS | |

| INSTALL ABOVE | |

| INSULATION | |

CONFINED | OUTLET | |

SPACE | ||

AIR TO | ||

| ATTIC 1 SQ. | |

| INCH PER | |

| 4000 BTUH |

| ALTERNATE |

|

|

|

|

| INLET AIR FROM | |||||

| AIR INLET |

|

|

|

|

| THE CRAWL SPACE | |||||

|

|

|

|

| ||||||||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| 1 SQ. INCH PER |

|

|

|

|

| OPEN | |||||

| 4000 BTUH |

|

|

|

|

| FOUNDATION |

|

| |||

|

|

|

|

|

| |||||||

|

|

|

|

|

|

|

| VENT | ||||

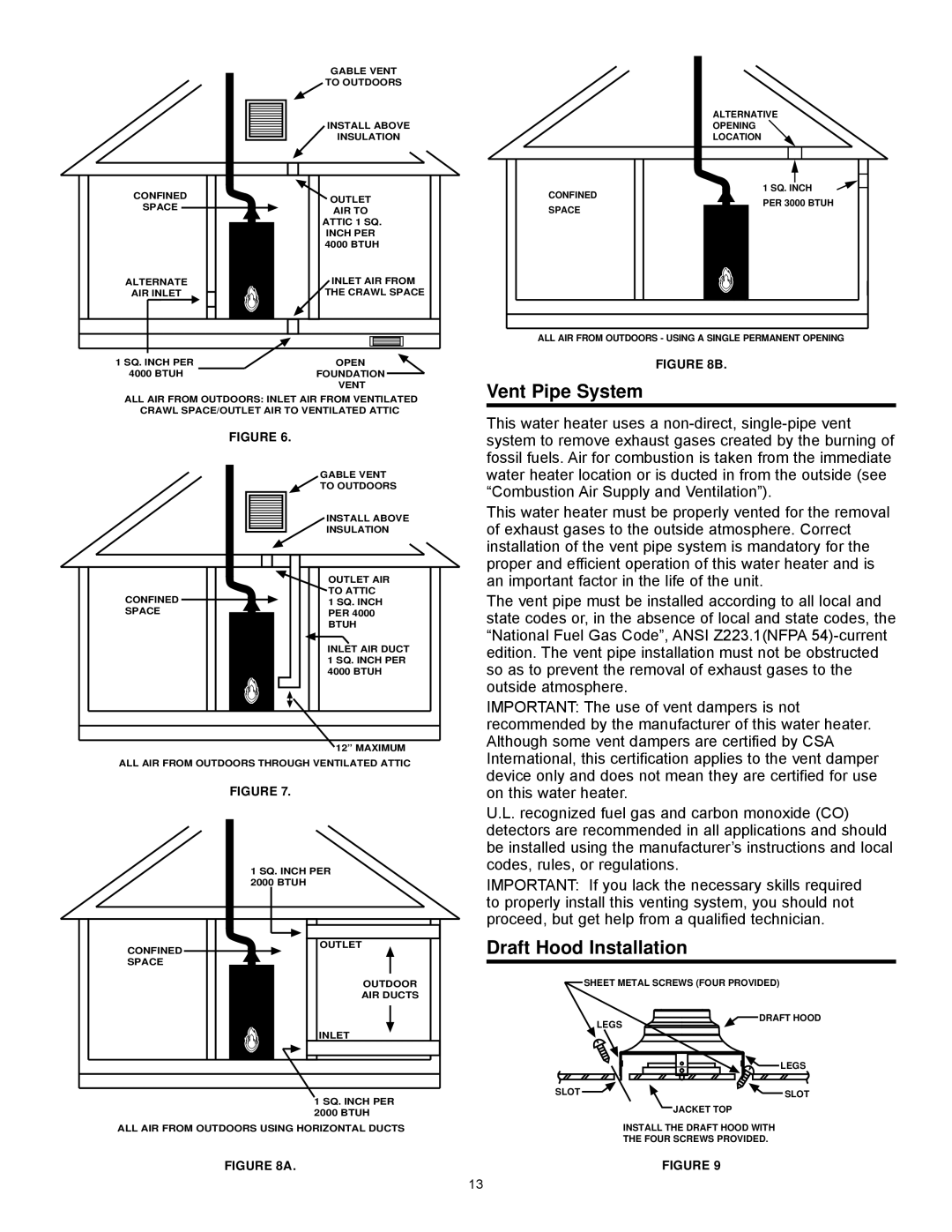

ALL AIR FROM OUTDOORS: INLET AIR FROM VENTILATED

CRAWL SPACE/OUTLET AIR TO VENTILATED ATTIC

FIGURE 6.

| GABLE VENT |

| TO OUTDOORS |

| INSTALL ABOVE |

| INSULATION |

| OUTLET AIR |

CONFINED | TO ATTIC |

1 SQ. INCH | |

SPACE | PER 4000 |

| BTUH |

INLET AIR DUCT 1 SQ. INCH PER 4000 BTUH

12” MAXIMUM ALL AIR FROM OUTDOORS THROUGH VENTILATED ATTIC

FIGURE 7.

| 1 SQ. INCH PER |

| 2000 BTUH |

CONFINED | OUTLET |

| |

SPACE |

|

| OUTDOOR |

| AIR DUCTS |

| ALTERNATIVE | |

| OPENING | |

| LOCATION | |

CONFINED | 1 SQ. INCH | |

PER 3000 BTUH | ||

SPACE | ||

|

ALL AIR FROM OUTDOORS - USING A SINGLE PERMANENT OPENING

FIGURE 8B.

Vent Pipe System

This water heater uses a

This water heater must be properly vented for the removal of exhaust gases to the outside atmosphere. Correct installation of the vent pipe system is mandatory for the proper and efficient operation of this water heater and is an important factor in the life of the unit.

The vent pipe must be installed according to all local and state codes or, in the absence of local and state codes, the “National Fuel Gas Code”, ANSI Z223.1(NFPA

IMPORTANT: The use of vent dampers is not recommended by the manufacturer of this water heater. Although some vent dampers are certified by CSA International, this certification applies to the vent damper device only and does not mean they are certified for use on this water heater.

U.L. recognized fuel gas and carbon monoxide (CO) detectors are recommended in all applications and should be installed using the manufacturer’s instructions and local codes, rules, or regulations.

IMPORTANT: If you lack the necessary skills required to properly install this venting system, you should not proceed, but get help from a qualified technician.

Draft Hood Installation

SHEET METAL SCREWS (FOUR PROVIDED)

INLET |

LEGS

DRAFT HOOD

1 SQ. INCH PER

2000 BTUH

ALL AIR FROM OUTDOORS USING HORIZONTAL DUCTS

FIGURE 8A.

LEGS |

SLOT | SLOT |

| JACKET TOP |

INSTALL THE DRAFT HOOD WITH

THE FOUR SCREWS PROVIDED.

FIGURE 9

13