6Configurable Settings

This section describes the proper setup of the

Many of the variables and setup parameters have been preset at the factory and do not need to be changed. However, this section of the manual will address all of the setup parameters that were available at the time of printing. The purpose of this is to familiarize the reader with all the setup parameters and their usage.

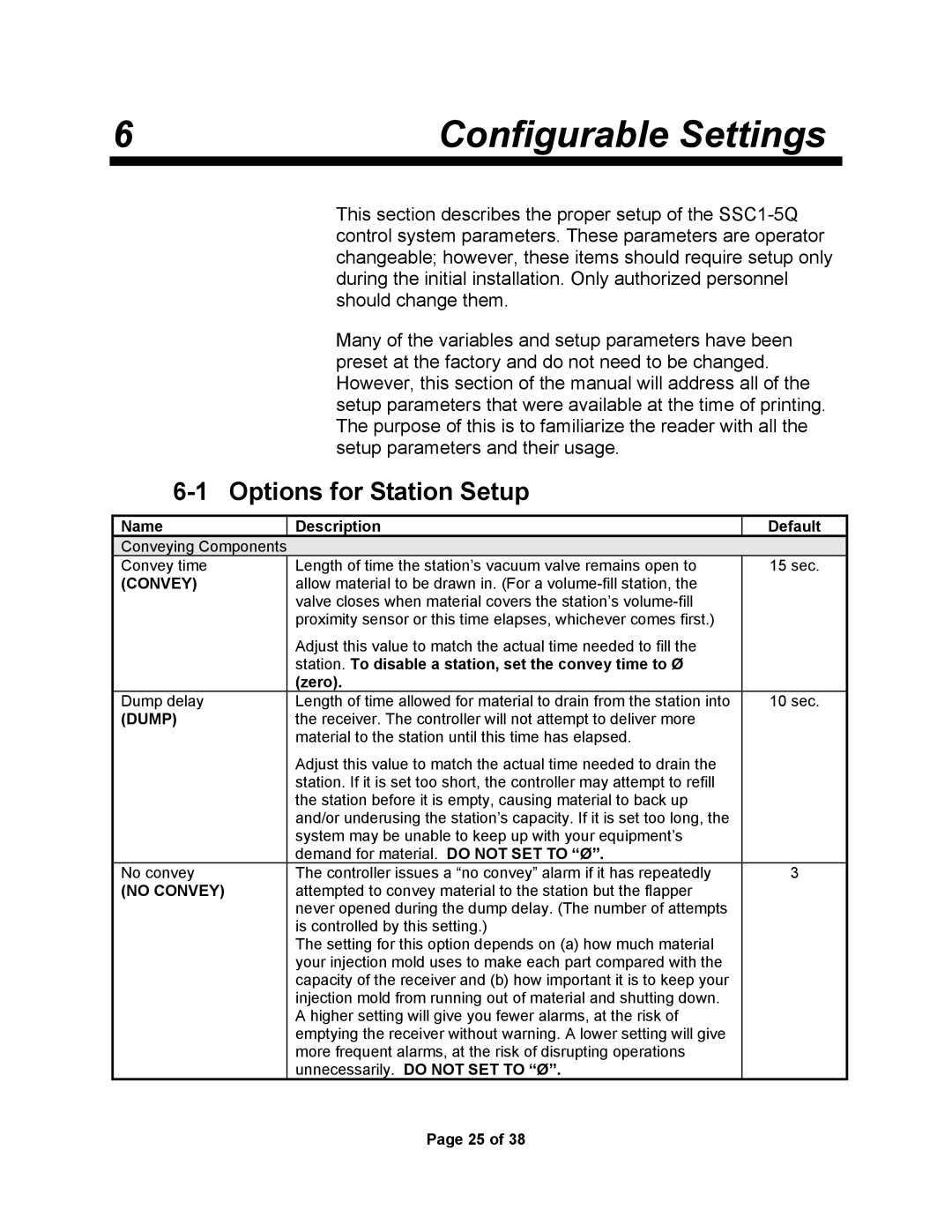

6-1 Options for Station Setup

Name | Description | Default |

Conveying Components |

|

|

Convey time | Length of time the station’s vacuum valve remains open to | 15 sec. |

(CONVEY) | allow material to be drawn in. (For a |

|

| valve closes when material covers the station’s |

|

| proximity sensor or this time elapses, whichever comes first.) |

|

| Adjust this value to match the actual time needed to fill the |

|

| station. To disable a station, set the convey time to Ø |

|

| (zero). |

|

Dump delay | Length of time allowed for material to drain from the station into | 10 sec. |

(DUMP) | the receiver. The controller will not attempt to deliver more |

|

| material to the station until this time has elapsed. |

|

| Adjust this value to match the actual time needed to drain the |

|

| station. If it is set too short, the controller may attempt to refill |

|

| the station before it is empty, causing material to back up |

|

| and/or underusing the station’s capacity. If it is set too long, the |

|

| system may be unable to keep up with your equipment’s |

|

| demand for material. DO NOT SET TO “Ø”. |

|

No convey | The controller issues a “no convey” alarm if it has repeatedly | 3 |

(NO CONVEY) | attempted to convey material to the station but the flapper |

|

| never opened during the dump delay. (The number of attempts |

|

| is controlled by this setting.) |

|

| The setting for this option depends on (a) how much material |

|

| your injection mold uses to make each part compared with the |

|

| capacity of the receiver and (b) how important it is to keep your |

|

| injection mold from running out of material and shutting down. |

|

| A higher setting will give you fewer alarms, at the risk of |

|

| emptying the receiver without warning. A lower setting will give |

|

| more frequent alarms, at the risk of disrupting operations |

|

| unnecessarily. DO NOT SET TO “Ø”. |

|

Page 25 of 38