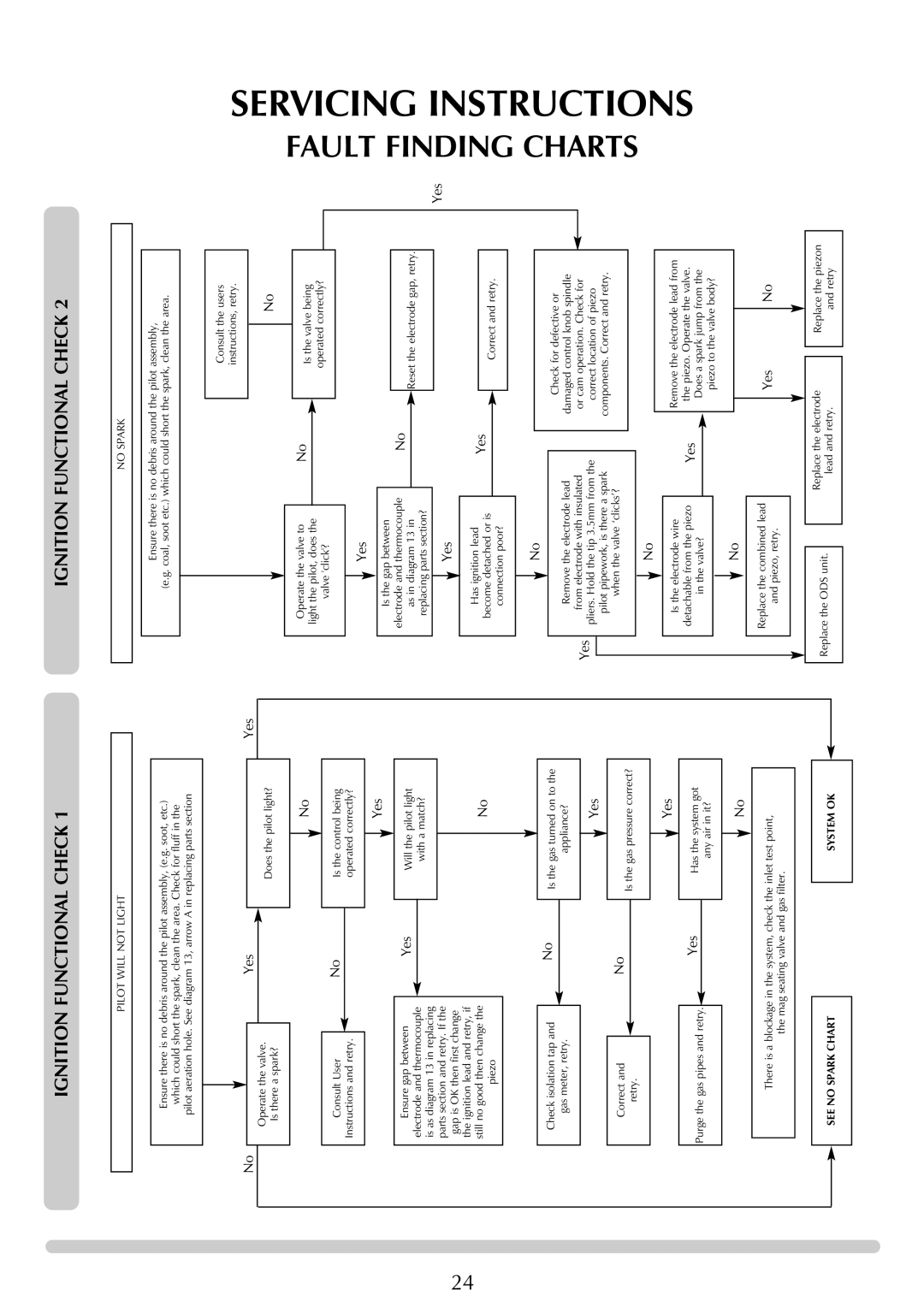

IGNITION FUNCTIONAL CHECK 1 | IGNITION FUNCTIONAL CHECK 2 |

PILOT WILL NOT LIGHT

Ensure there is no debris around the pilot assembly, (e.g. soot, etc.) which could short the spark, clean the area. Check for fluff in the pilot aeration hole. See diagram 13, arrow A in replacing parts section

NO SPARK

Ensure there is no debris around the pilot assembly,

(e.g. coal, soot etc.) which could short the spark, clean the area.

No |

| Yes |

| ||

Operate the valve. | Does the pilot light? | ||||

|

|

| |||

| Is there a spark? |

|

| ||

|

|

|

| ||

|

|

|

|

| |

No

Yes

Operate the valve to

light the pilot, does the

valve 'click'?

Consult the users instructions, retry.

No

No | Is the valve being |

| operated correctly? |

Consult User |

| No |

| ||

Instructions and retry. |

|

| Yes |

| |

|

|

|

|

| |

|

|

|

| ||

Ensure gap between |

|

| |||

electrode and thermocouple |

|

|

| ||

|

|

| |||

is as diagram 13 in replacing |

|

|

| ||

Is the control being operated correctly?

Yes

Will the pilot light

with a match?

Yes

Is the gap between

electrode and thermocouple

as in diagram 13 in

replacing parts section?

No

![]() Reset the electrode gap, retry.

Reset the electrode gap, retry.

24

parts section and retry. If the |

|

|

|

| |||

gap is OK then first change |

|

|

|

| |||

the ignition lead and retry, if |

|

|

|

| |||

still no good then change the |

|

|

|

| |||

piezo |

|

|

|

| |||

|

|

|

|

| No |

| |

|

|

|

|

| |||

Check isolation tap and |

|

|

| ||||

gas meter, retry. |

|

|

|

|

| ||

|

| No |

|

| |||

|

|

|

|

|

|

| |

|

|

|

|

|

|

| |

Correct and |

|

|

|

|

|

| |

retry. |

|

|

|

|

|

| |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

|

|

|

| Yes | ||

Purge the gas pipes and retry. |

|

| |||||

|

|

|

|

| |||

|

|

|

|

|

|

|

|

No

Is the gas turned on to the

appliance?

Yes

Is the gas pressure correct?

Yes

Has the system got

any air in it?

No

Yes

|

| Has ignition lead |

| Yes |

|

|

|

|

| ||

|

| become detached or is |

|

|

|

|

| Correct and retry. | |||

|

|

|

|

|

|

|

|

| |||

|

| connection poor? |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| No |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

| Check for defective or | |||

|

|

|

|

|

|

|

|

|

| ||

|

| Remove the electrode lead |

|

| |||||||

|

|

|

|

| damaged control knob spindle | ||||||

Yes | from electrode with insulated |

|

|

|

| or cam operation. Check for | |||||

pliers. Hold the tip 3.5mm from the |

|

|

|

| correct location of piezo | ||||||

|

|

|

|

|

| ||||||

|

| pilot pipework, is there a spark |

|

|

| components. Correct and retry. | |||||

|

| when the valve ‘clicks’? |

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

|

| No |

|

|

|

|

|

|

| |

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

| Remove the electrode lead from | ||

|

| Is the electrode wire |

|

|

|

|

| ||||

|

| detachable from the piezo |

| Yes |

|

|

| the piezo. Operate the valve. | |||

|

| in the valve? |

|

|

|

|

|

| Does a spark jump from the | ||

|

|

|

|

|

|

|

|

|

|

| piezo to the valve body? |

|

|

| No |

|

| ||||||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

| Replace the combined lead |

|

|

|

|

|

|

| ||

Yes

There is a blockage in the system, check the inlet test point,

the mag seating valve and gas filter.

SEE NO SPARK CHART |

| SYSTEM OK |

|

|

|

| and piezo, retry. |

| Yes |

| No | |

|

|

|

|

| ||

|

|

|

|

|

|

|

|

|

|

|

|

|

|

Replace the ODS unit. |

|

| Replace the electrode |

| Replace the piezon | |

|

| lead and retry. |

| and retry | ||

|

|

|

|

| ||

|

|

|

|

|

|

|