GENERAL

The STOW

The drum batch capacity of these mixers is between 3.5 and

4.0bags. With proper care, they will give continuous service

This mixer can be powered by either gasoline or electric motors. The power from the engine is transmitted via the clutch/ reduction assembly directly to the paddle shaft. Therefore providing high mixer torque and eliminating

BEFORE STARTING

Before starting the engine, read the engine owners manual and thoroughly understand the safety information.

Check the items listed below:

OIL LEVELS

Be sure to check the oil levels in the engine and engine reduction unit before starting the unit.

HARDWARE

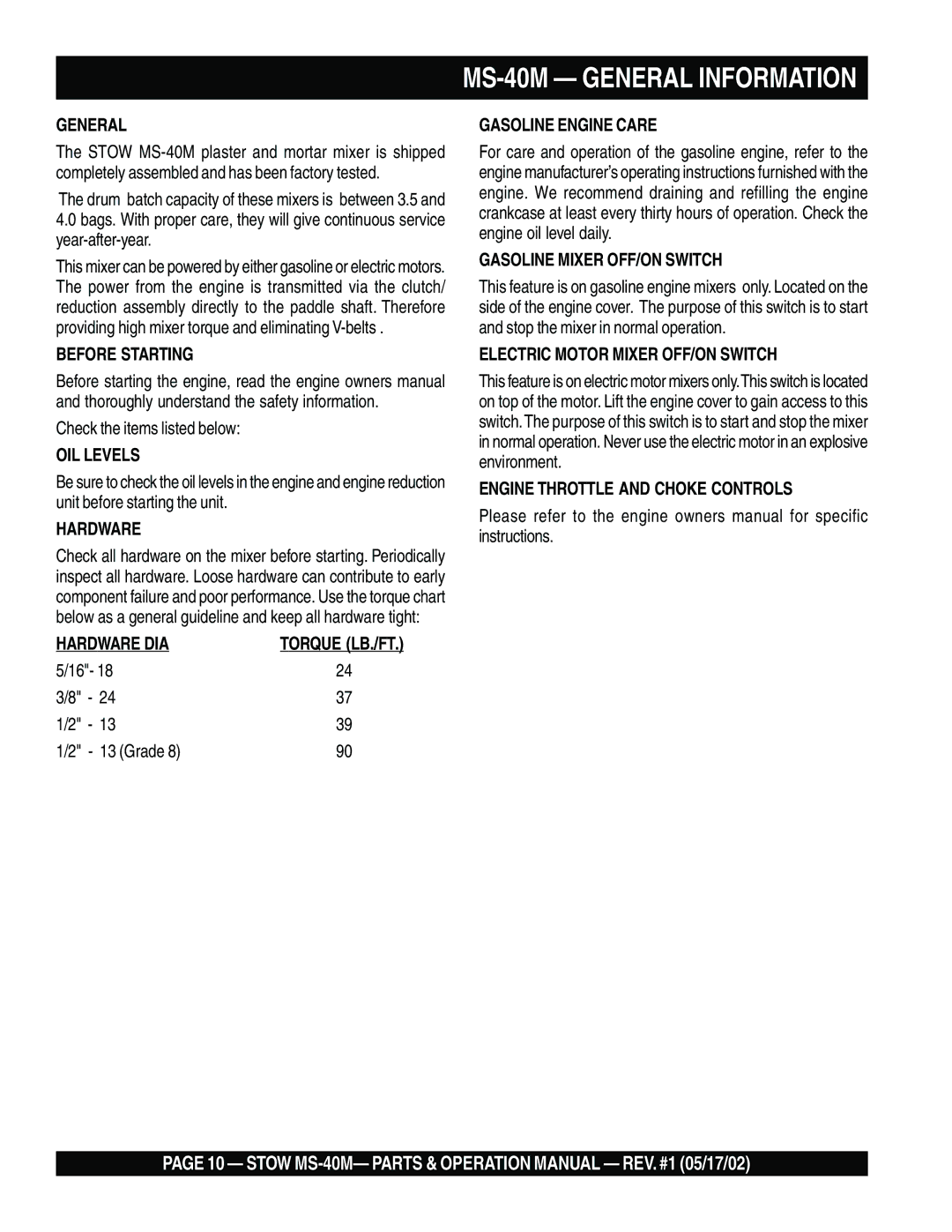

Check all hardware on the mixer before starting. Periodically inspect all hardware. Loose hardware can contribute to early component failure and poor performance. Use the torque chart below as a general guideline and keep all hardware tight:

HARDWARE DIA | TORQUE (LB./FT.) |

5/16"- 18 | 24 |

3/8" - 24 | 37 |

1/2" - 13 | 39 |

1/2" - 13 (Grade 8) | 90 |

MS-40M — GENERAL INFORMATION

GASOLINE ENGINE CARE

For care and operation of the gasoline engine, refer to the engine manufacturer’s operating instructions furnished with the engine. We recommend draining and refilling the engine crankcase at least every thirty hours of operation. Check the engine oil level daily.

GASOLINE MIXER OFF/ON SWITCH

This feature is on gasoline engine mixers only. Located on the side of the engine cover. The purpose of this switch is to start and stop the mixer in normal operation.

ELECTRIC MOTOR MIXER OFF/ON SWITCH

This feature is on electric motor mixers only.This switch is located on top of the motor. Lift the engine cover to gain access to this switch.The purpose of this switch is to start and stop the mixer in normal operation. Never use the electric motor in an explosive environment.

ENGINE THROTTLE AND CHOKE CONTROLS

Please refer to the engine owners manual for specific instructions.

PAGE 10 — STOW