MS15E, MS15H5.5 specifications

The Stow MS15H5.5 and MS15E represent advanced options in the realm of industrial cleaning machinery, specifically designed for effectiveness and efficiency in various cleaning applications. These models cater to the demands of different environments, such as warehouses, retail spaces, and manufacturing facilities.The MS15H5.5 is powered by a robust Honda engine, delivering superior cleaning power while ensuring reliability and longevity. This model features a high-pressure washer that efficiently tackles tough grime and stains, making it ideal for heavy-duty cleaning tasks. The Honda engine is known for its fuel efficiency, allowing for longer operational use without frequent refueling. It boasts a durable design with a reinforced steel frame, providing stability and toughness to withstand rigorous use.

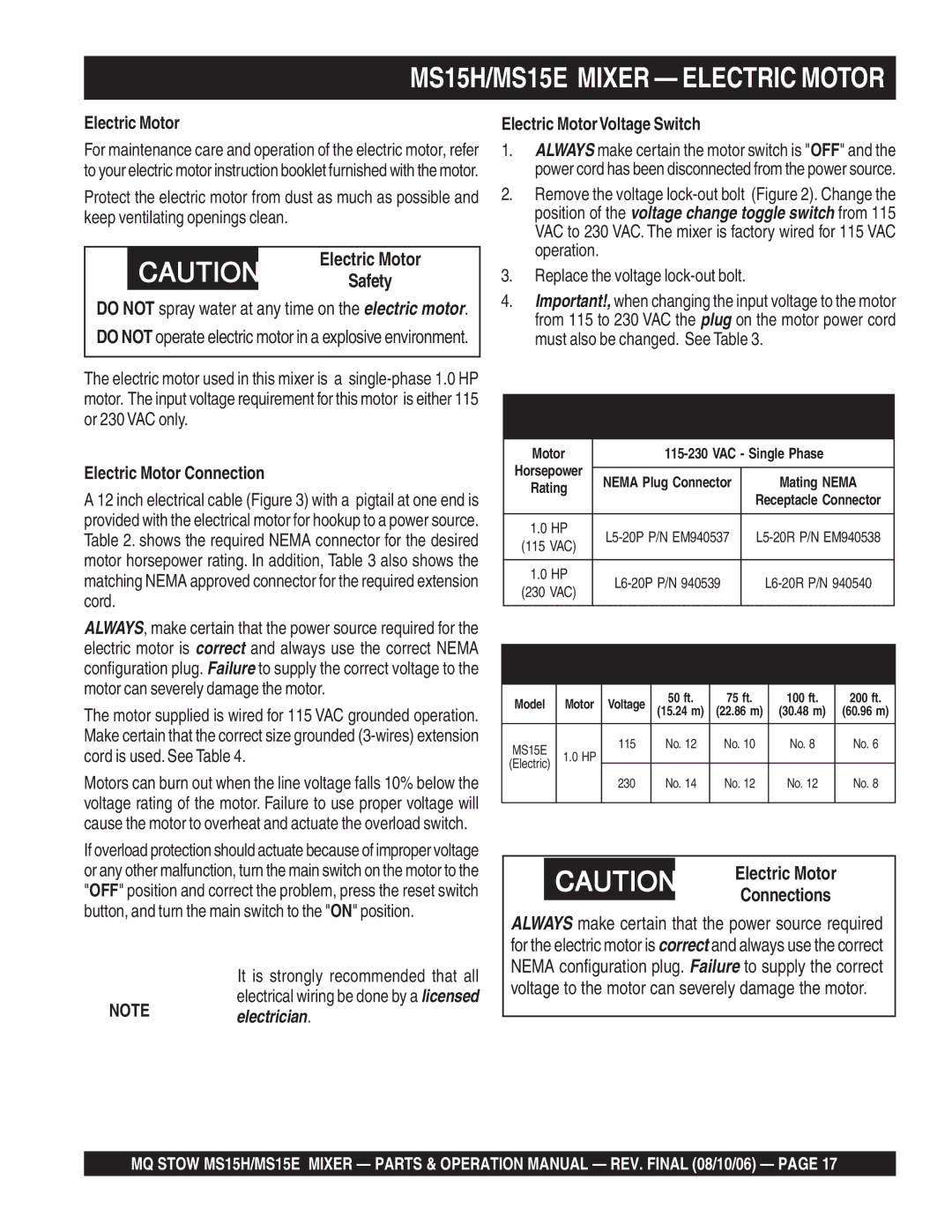

On the other hand, the MS15E is an electric model that offers a quieter alternative for cleaning operations where noise reduction is crucial. This electric version is equipped with a powerful motor that provides consistent pressure for effective cleaning. The MS15E is valued for its ease of use and lower maintenance requirements compared to its gas-powered counterpart. Users appreciate its lightweight construction, which makes it easily maneuverable for various cleaning tasks.

Both the MS15H5.5 and MS15E incorporate advanced technology features such as an adjustable pressure setting, giving users better control over the cleaning intensity based on the surface being cleaned. This feature not only enhances cleaning efficacy but also extends the lifespan of the equipment and surfaces being serviced.

Safety is another critical aspect of both models. They come equipped with thermal relief valves that prevent overheating, ensuring safe operation during prolonged use. The ergonomic design of the handles and controls provides comfort to the operator, reducing fatigue during extended periods of cleaning.

In summary, the Stow MS15H5.5 and MS15E are versatile cleaning machines that excel in performance, durability, and user-friendliness. Whether powered by gas or electricity, these models are designed to tackle various cleaning challenges effectively, making them valuable assets for any cleaning operation.