STR36SP

Proposition 65WARNING

Silicosis Warning

SILCOSIS/RESPIRATORYWARNINGS

Table of Contents

Order via Fax Dealers Only

Parts Ordering Procedures

Best Deal! Order via Internet Dealers Only

Machine layout, location of components, checking of engine

Training Checklist

Daily PRE-OPERATION Checklist

Daily PRE-OPERATION Checklist

You can be Injured if you do not follow these directions

STR36SP-SERIES Safety Message Alert Symbols

Always wear approved eye and hearing protection

STR36SP-SERIES Safety Message Alert Symbols

Always wear approved respiratory protection

Fatigue, illness or taking medicine

Do not operate or service this equipment

Lifting the Ride-On Trowel

STR36SP-SERIES Rules for Safe Operation

Always keep the work area well organized

Transporting

Towing Safety Precautions

Battery

STR36SP-SERIES Rules for Safe Operation

Always know the location of the nearest first aid kit

Maintenance Safety

Emergencies

Machine Safety Decals

STR36SP-SERIES Operation and Safety Decals

TBD

STR36SP-SERIES- Specifications Trowel

STR36 Engine Specifications

STR36SP-SERIES- Specifications Engine

STR36SP-SERIES General Information

STR36SP-SERIES Controls and Indicators

Safety Stop Switch Shuts down engine when seat is empty

STR36SP-SERIES Controls and Indicators

Flow of fuel

STR36SP-SERIES Basic Engine

Element

Mixture

Seat Assembly

STR36SP-SERIES NEW Machine Setup Instructions

Trowel Pre-Set Up Instructions

Control Handle Assembly

Gearbox Oil Level

Engine Oil Level Always check engine oil Before Each USE

STR36SP-SERIES Operation

Steering

STR36SP-SERIES Operation

STR36SP-SERIES Maintenance

STR36SP-SERIES Maintenance

Have a 3/4 X 1 X 3-1/4 inch wooden block available

Checking The Drive Belt

Removing the Drive Belt

CV-Joint

STR36SP-SERIES- Maintenance

Reinstall the spare belt carrier and the drive belt guard

Wooden Block

Spare Drive Belt Replacement

STR36SP-SERIES- Maintenance

Torque Converter/Variable Pitch Pulley Drive Pulley

Drive System Theory of Operation

Matching Blade Pitch for Both Sets of Blades

How It Works Figure Condition a Engine Idling

Clutch

Blade Pitch

Stabilizer Ring Removal

Trowel Arm adjustment Procedure

Spider Plate Hex Head Bolt Zerk Fitting

Trowel Arm Removal

Remove the trowel arm from the spider plate

Trowel Blade Removal

Checking Trowel Arm Straightness

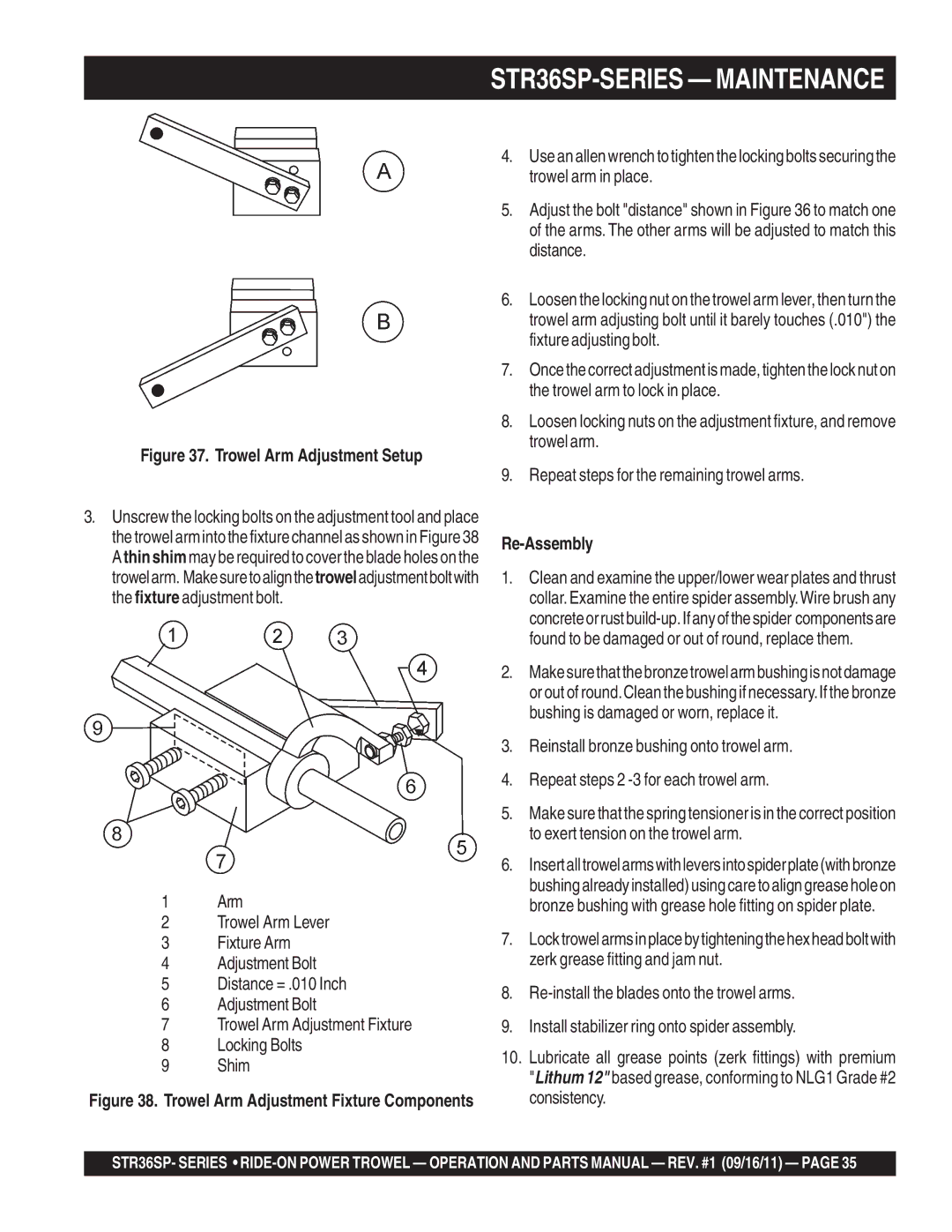

Trowel Arm Adjustment

Re-Assembly

Trowel Arm Adjustment Setup

Decommissioning Trowel/Components

Installing Pans Onto Finisher Blades

STR36SP-SERIES -TROUBLESHOOTING Engine

STR36SP-SERIES -TROUBLESHOOTING Engine

Troubleshooting

STR36SP-SERIES-TROUBLESHOOTING Trowel

Troubleshooting

STR36SP-SERIES-TROUBLESHOOTING Trowel

STR36SP-SERIES Notes

Xxxxx only Not Used on

STR36SP-SERIES Explanation of Codes in Remarks Column

STR36SP-SERIES Suggested Spare Parts

Decals

STR36SP-SERIES Decals

DECAL, Protective Clothing

DECAL, Spring Safety

DECAL, Powder Coated TBD DECAL, Stow

DECAL, AL. Pitch RH TBD DECAL, AL. Pitch LH

Pivot ASSY. RIGHT/LEFT

STR36SP-SERIES Pivot ASSY. RIGHT/LEFT

ARM, Pivot Right Hand

WASHER, LOCK, 3/8 MED

BAR, 1 Control Pivot

Rocker BLOCK, 1.0 Hole

Steering Handles ASSY, Left and Right

STR36SP-SERIES Steering Handles ASSY. Left and Right

HANDLE, STEERING, Lower

GRIP, Handle

ROD END, 3/8-24 Male RH

HANDLE, Tube

Steering Control ASSY., Left and Right

STR36SP-SERIES Steering Control ASSY. Left and Right

WASHER, Lock 3/8 MED

Assist ASSEMBLY, Steering

ROD END, 1/2-20 Male RH

WASHER, Flat 1/2 SAE

Gearbox ASSY. Right Side

STR36SP-SERIES Gearbox ASSY. Right Side

20353

20065

5031A SCREW, RHM 1/4- 20 X 1/2 0948

12981

Gearbox ASSY. Left Side

STR36SP-SERIES Gearbox ASSY. Left Side

12%+ 0232A

12982

10989 STUD, N10- 32 X 3/4 12907

10% 12583 SPACER, X 11D X 1.168L 11%+ 9045

Single Pitch Handle ASSY. Left and Right

STR36SP-SERIES Single Pitch Handle ASSY. Left and Right

Crank Lever

Cable Assembly

Crank Knob

Spacer

Drive Assy

STR36SP-SERIES Drive Assy

KEY, Woodruff #9

GASKET, CV Joint Boot

BOOT, CV Joint

PLATE, Bearing Mount

MUFFLER/BELT Assy

STR36SP-SERIES MUFFLER/BELT Assy

WASHER, Flat 5/16 USS

ENGINE, Honda 24 HP GX670

MUFFLER, 24 Honda

WASHER, Lock 5/16 Medium

Belt Guard Assy

STR36SP-SERIES Belt Guard Assy

Belt Guard

Spider ASSY. Right

STR36SP-SERIES Spider ASSY. Right

Wear Ring

SCREW, Trowel Adjustment

Blade Assembly

PLATE, Wear Thrust Collar

Spider ASSY. Left

STR36SP-SERIES Spider ASSY. Left

ARM, Trowel Left

SPRING, LH Trowel ARM Lever

LEVER, Trowel ARM Left Hand

Yoke Assy

STR36SP-SERIES -YOKE Assy

PIN, Yoke

Yoke

Foot PEDALS/THROTTLE Assy

STR36SP-SERIES Foot PEDALS/THROTTLE Assy

RISER, Left Foot

CABLE, Control 10-32 X 33 Long

SPRING, Throttle Return

WASHER, Flat #10 SAE

Control Panel Assy

STR36SP-SERIES Control Panel Assy

HARNESS, Wire Honda Rider

SWITCH,TOGGLE Electric #9061

Wire ASSEMBLY, 16 GA. X

BOOT, Toggle Switch

FRAME/FUEL Assy

STR36SP-SERIES FRAME/FUEL Assy

BUSHING, Rubber Fuel

Fuel Pump Assembly

TANK, Fuel Five Gallon

Fuel CAP/GAUGE

Battery Assy

STR36SP-SERIES Battery Assy

BOOT, Terminal

Bracket Battery HOLD- Down

BOLT, Battery Hold Down

BOX, Battery GR UI

Seat Frame Assy

STR36SP-SERIES Seat Frame Assy

Seat Plate

CONNECTOR, Relay

SWITCH, Kill COLE- HER #90036

TERMINAL, Wire Pioneer

AIR Cleaner Assy

Honda GX-670 AIR Cleaner Assy

PLATE, AIR Cleaner Setting

CLIP, AIR Cleaner

SEAL, AIR Cleaner Housing

SEAL, AIR Cleaner Cover

Camshaft Assy

Honda GX-670 Camshaft Assy

ARM, Valve Rocker

SPRING, Weight Return

SEAL, Valve Stem

ROD, Push

Carburetor Assy

Honda GX-670 Carburetor Assy

Gasket SET

GASKET, AIR Cleaner

TUBE, Breather

CLIP, Breather Tube

Control 2 Assy

Honda GX-670 Control Assy

ARM, Governor

Lever ASSEMBLY,THROTTLE

JOINT, ROD

SPRING, Starter

Control BOX Assy

Honda GX-670 Control BOX Assy

CASE, Control BRACKET, Case Mounting

BRACKET, Wire Harness Clip SUB- Wire Harness Assembly

KEY Comp HOLDER, Stop Switch Wire

SCREW, Special 6 X CLIP, Wire Harness

Crankcase Cover Assy

Honda GX-670 Crankcase Cover Assy

PIN, Governor Weight

Cover ASSEMBLY, OIL Pump

WEIGHT, Governor

HOLDER, Governor Weight

Crankshaft Assy

Honda GX-670 Crankshaft Assy

90401ZJ1000

Crankshaft COMP., T-TYPE

Cylinder Barrelassy

Honda GX-670 Cylinder Barrel Assy

GASKET, Breather Cover

CLAMP, Wire

SWITCH, OIL Pressure

COVER, Breather

Cylinder Head Assy

Honda GX-670 Cylinder Head Assy

GASKET, Cylinder Head

HANGER, Engine

GUIDE, Valve OS, Optional

CLIP, Valve Guide

FAN Cover Assy

Honda GX-670 FAN Cover Assy

SHROUD, Right

COVER, FAN *NH1* Black

PLATE, Right Side

PLATE, Left Side

FLY Wheel Assy

Honda GX-670 Flywheel Assy

FLY Wheel Comp

PLATE, Cooling FAN Setting

FAN, Cooling

GRID, Screen P.T.O. Optional

Fuel Pump Assy

Honda GX-670 Fuel Pump Assy

Tube B, Fuel

Pump ASSEMBLY, Fuel

STAY, Fuel Pump

TUBE, Fuel

Ignition Coil Assy

Honda GX-670 Ignition Coil Assy

Coil ASSEMBLY, Charge 12V/20A

Coil Assembly R. Ignition

GROMMET, Ignition Wire

Coil ASSEMBLY, L.. Ignition

Labels Assy

Honda GX-670 Labels Assy

MARK, Emblem

Honda GX-670 Labels Assy

OIL Cooler Assy

Honda GX-670 OIL Cooler Assy

Hose A, OIL

Collar 12MM

Cooler COMP., OIL

GRILLE, OIL Cooler

Piston + Connecting ROD Assy

Honda GX-670 Piston + Connecting ROD Assy

Ring SET, Piston 0.75 Optional

ROD Assembly Connecting

BOLT, Connecting ROD 6 X

Ring SET, Piston STD

Starter Motor Assy

Honda GX-670 Starter Motor Assy

LEVER, Pinion Drive

Switch ASSEMBLY, Magnet

RING, Snap Denso

Collar SET, Clutch Stop

Payment Terms

Terms and Conditions of Sale Parts

STR36SP-SERIES-NOTES

HERE’S HOW to GET Help