Sub-Zero specifications

Sub-Zero is synonymous with luxury refrigeration, renowned for its high-quality products that combine aesthetics, functionality, and innovative technology. Founded in 1945, the brand has carved a niche for itself as a pioneer in the refrigeration and preservation of food. Their commitment to exceptional performance and durability has established Sub-Zero as a favored choice for both culinary enthusiasts and professional chefs.One of the standout features of Sub-Zero refrigeration units is their dual refrigeration system. Unlike traditional models that use a single cooling system for both the refrigerator and freezer compartments, Sub-Zero’s design employs two independent systems. This not only optimizes temperature control for each compartment but also maintains optimal humidity levels, which is essential for preserving the freshness of food longer.

Another defining characteristic of Sub-Zero models is their advanced air purification system. Incorporating NASA-inspired technology, the air purification system utilizes a combination of UV light and a carbon filter to eliminate airborne bacteria and mold. This feature ensures that the refrigerator environment remains pristine, significantly extending the lifespan of produce and other perishables.

Moreover, Sub-Zero appliances come with customizable interior shelving and storage options. Users can configure the layout to maximize space efficiency, accommodating items of various sizes. The adjustable shelves and bins are designed to be both functional and visually appealing, ensuring that organization within the unit is seamless.

Energy efficiency is also a hallmark of Sub-Zero’s commitment to sustainability. Many models are ENERGY STAR certified, reflecting the use of materials and technology designed to minimize energy consumption while still providing powerful performance.

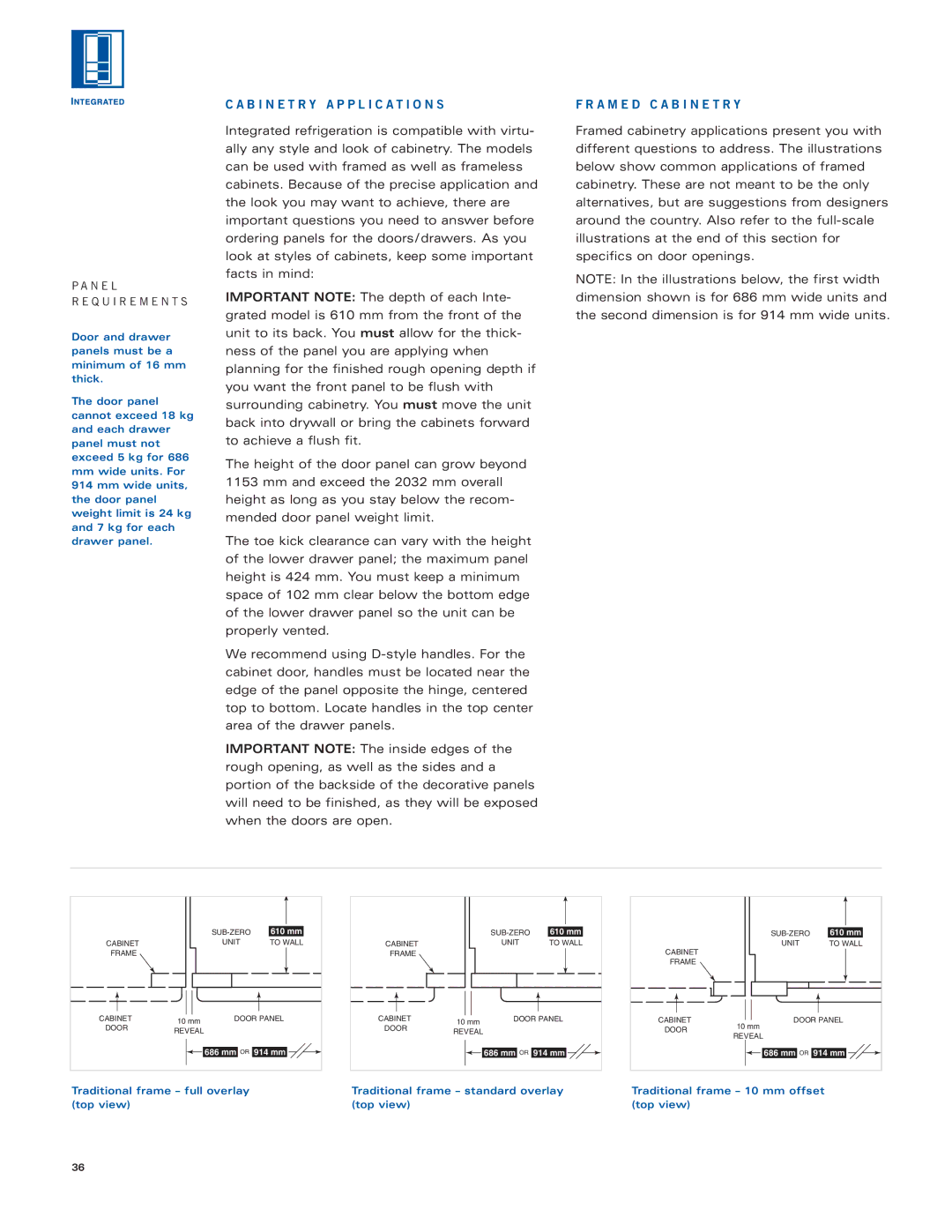

In addition, Sub-Zero offers a range of style options, including integrated and built-in designs that fit seamlessly into any kitchen aesthetic. With customizable paneling options, Sub-Zero appliances can blend with cabinetry, creating a cohesive look that enhances the overall elegance of the space.

Overall, Sub-Zero’s dedication to quality, performance, and design innovation sets it apart in the competitive world of refrigeration. With features that prioritize food preservation, user convenience, and energy efficiency, Sub-Zero remains a top choice for those seeking the ultimate in luxury kitchen appliances.