Stopping the Engine

Idle the engine briefly before stopping (about 2 minutes), then slide the ignition switch to the "O" (Engine OFF) position.

OFF

ure 21

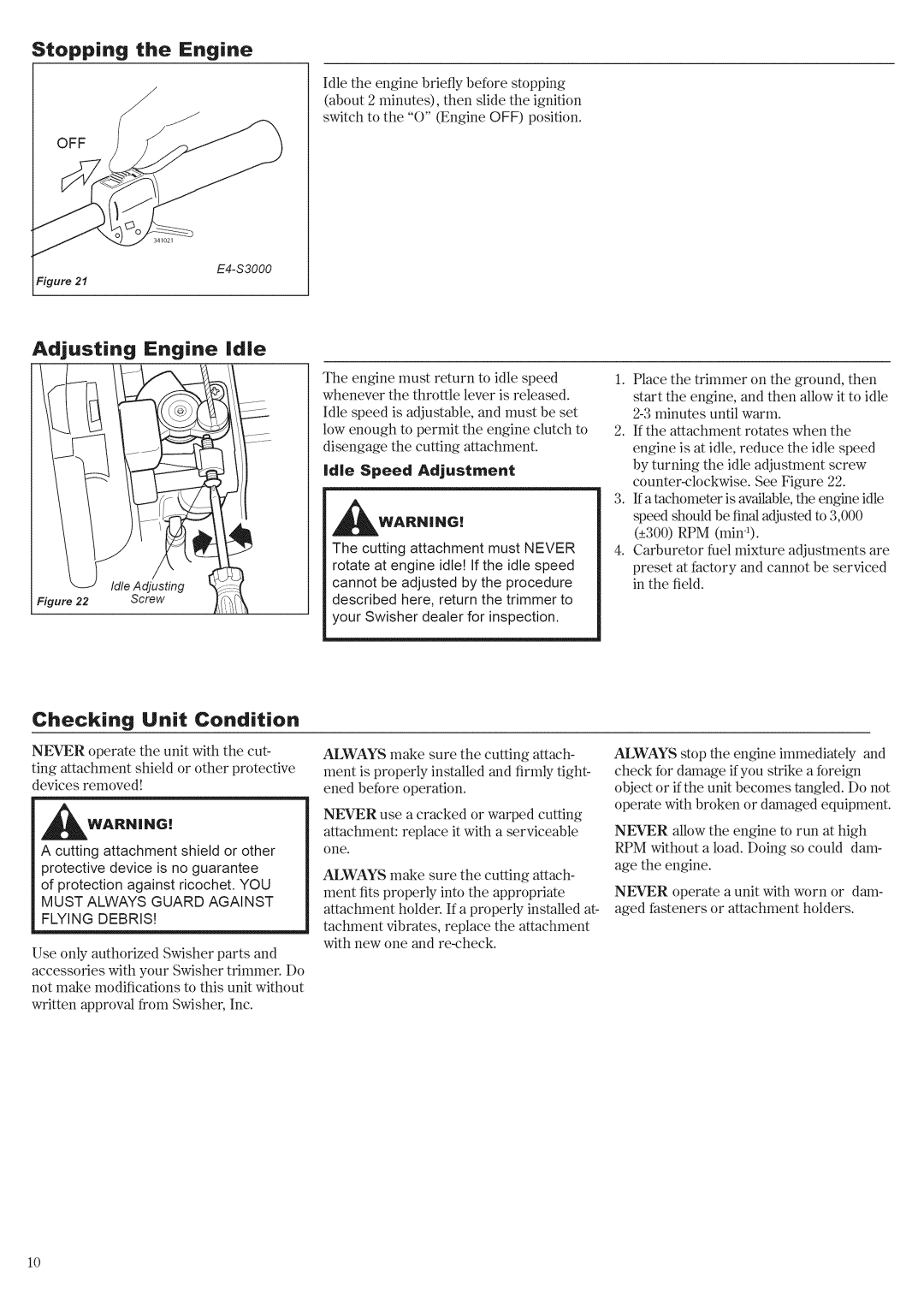

Adjusting Engine die

__lJ

Figure 22 Idle

The engine must return to idle speed whenever the throttle lever is released.

Idle speed is adjustable, and must be set low enough to permit the engine clutch to disengage the cutting attachment.

die Speed Adjustment

WARNING!

The cutting attachment must NEVER rotate at engine idle! If the idle speed cannot be adjusted by the procedure described here, return the trimmer to your Swisher dealer for inspection,

1.Place the trimmer on the ground, then start the engine, and then allow it to idle

2.If the attachment rotates when the engine is at idle, reduce the idle speed by turning the idle adjustment screw

3.If a tachometer is available, the engine idle speed should be final adjusted to 3,000 (_+300)RPM

4.Carburetor fuel mixture adjustments are preset at factory and cannot be serviced in the field.

Checking Unit Condition

NEVER operate the unit with the cut- ting attachment shield or other protective devices removed!

WARNNG!

A cutting attachment shield or other protective device is no guarantee of protection against ricochet. YOU MUST ALWAYS GUARD AGAINST FLYING DEBRIS!

Use only authorized Swisher parts and

accessories with your Swisher trimmer. Do

not make modifications to this unit without

written approval from Swisher, Inc.

ALWAYS make sure the cutting attach- ment is properly installed and firmly tight- ened before operation.

NEVER use a cracked or warped cutting attachment: replace it with a serviceable

one.

ALWAYS make sure the cutting attach- ment fits properly into the appropriate attachment holder. If a properly installed at- tachment vibrates, replace the attachment with new one and

ALWAYS stop the engine immediately and check for damage if you strike a foreign object or if the unit becomes tangled. Do not operate with broken or damaged equipment.

NEVER allow the engine to run at high RPM without a load. Doing so could dam- age the engine.

NEVER operate a unit with worn or dam- aged fasteners or attachment holders.

10