10/15-Hour Maintenance

|

| Clean | the spark plug | |

inch | and check the gap at | |||

the | electrode. | |||

7 mm) | ||||

|

| |||

Figure 29

50-hour Maintenance

Every 50 hours of operation

(more frequently in dusty or dirty conditions):

IIRemove and clean the cylinder cover and clean grass and dirt from the cylinder fins.

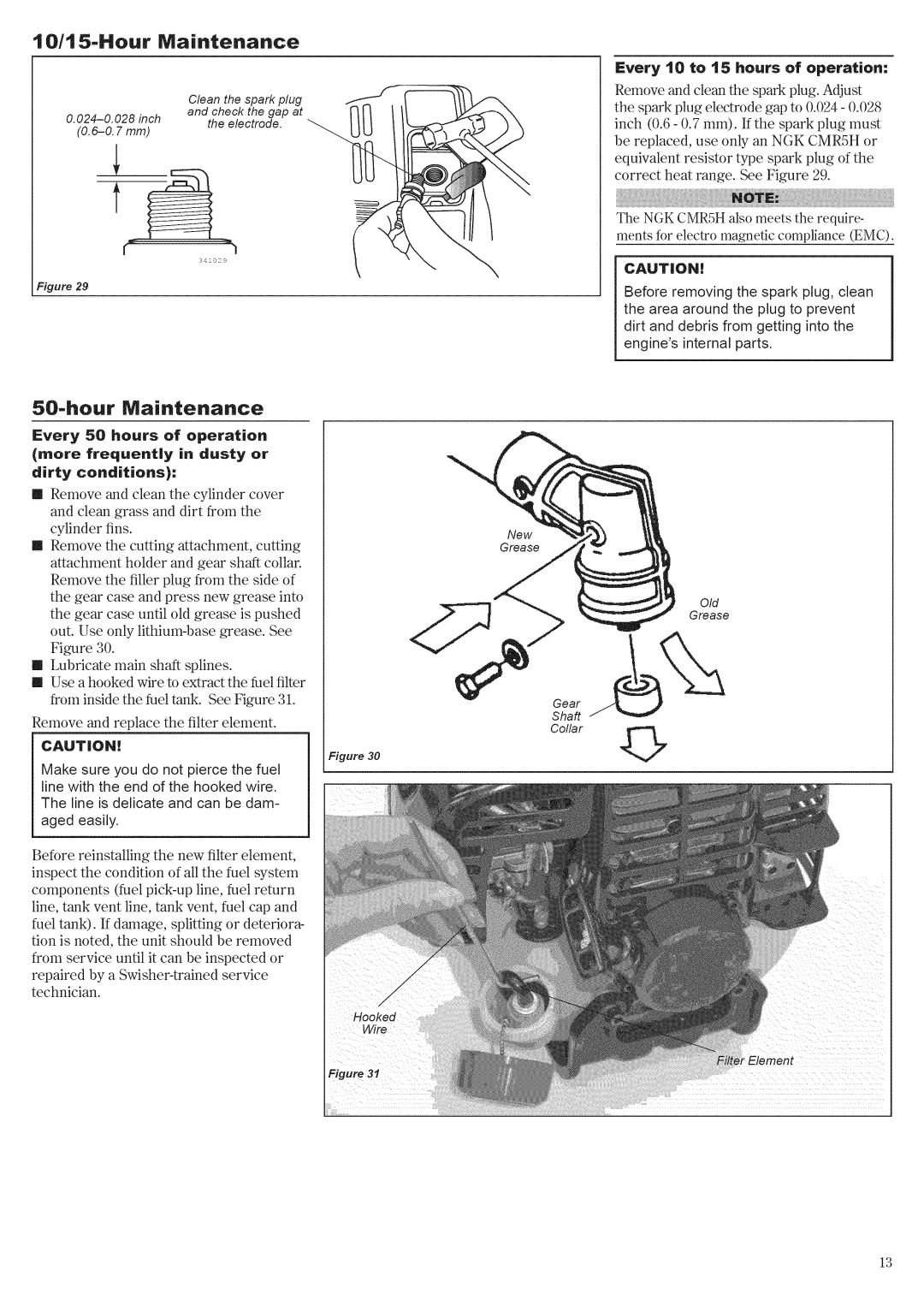

IIRemove the cutting attachment, cutting attachment holder and gear shaft collal: Remove the filler plug from the side of the gear case and press new grease into the gear case until old grease is pushed out. Use only

II Lubricate main shaft splines.

IIUse a hooked wire to extract the fuel filter from inside the fuel tank. See Figure 31.

Remove and replace the filter element.

CAUTON!

Figure 30

Make sure you do not pierce the fuel line with the end of the hooked wire.

The line is delicate and can be dam-

aged easily.

Before reinstalling the new filter element, inspect the condition of all the fuel system components (fuel

Every 10 to 15 hours of operation:

Remove and clean the spark plug. Adjust

the spark plug electrode gap to 0.024 - 0.028 inch (0.6 - 0.7 ram). If the spark plug must be replaced, use only an NGK CMR5H or equivalent resistor type spark plug of the correct heat range. See Figure 29.

The NGK CMR5H also meets the require- ments for electro magnetic compliance (EMC).

CAUTION!

Before removing the spark plug, clean the area around the plug to prevent dirt and debris from getting into the engine's internal parts,

New

Grease

Old

Grease

Gear

Shaft

Collar C_

13