4.0 MAINTENANCE SCHEDULE

The maintenance requirements of the T201 are the same as a standard T200 NOx analyzer but with additional maintenance items (Table

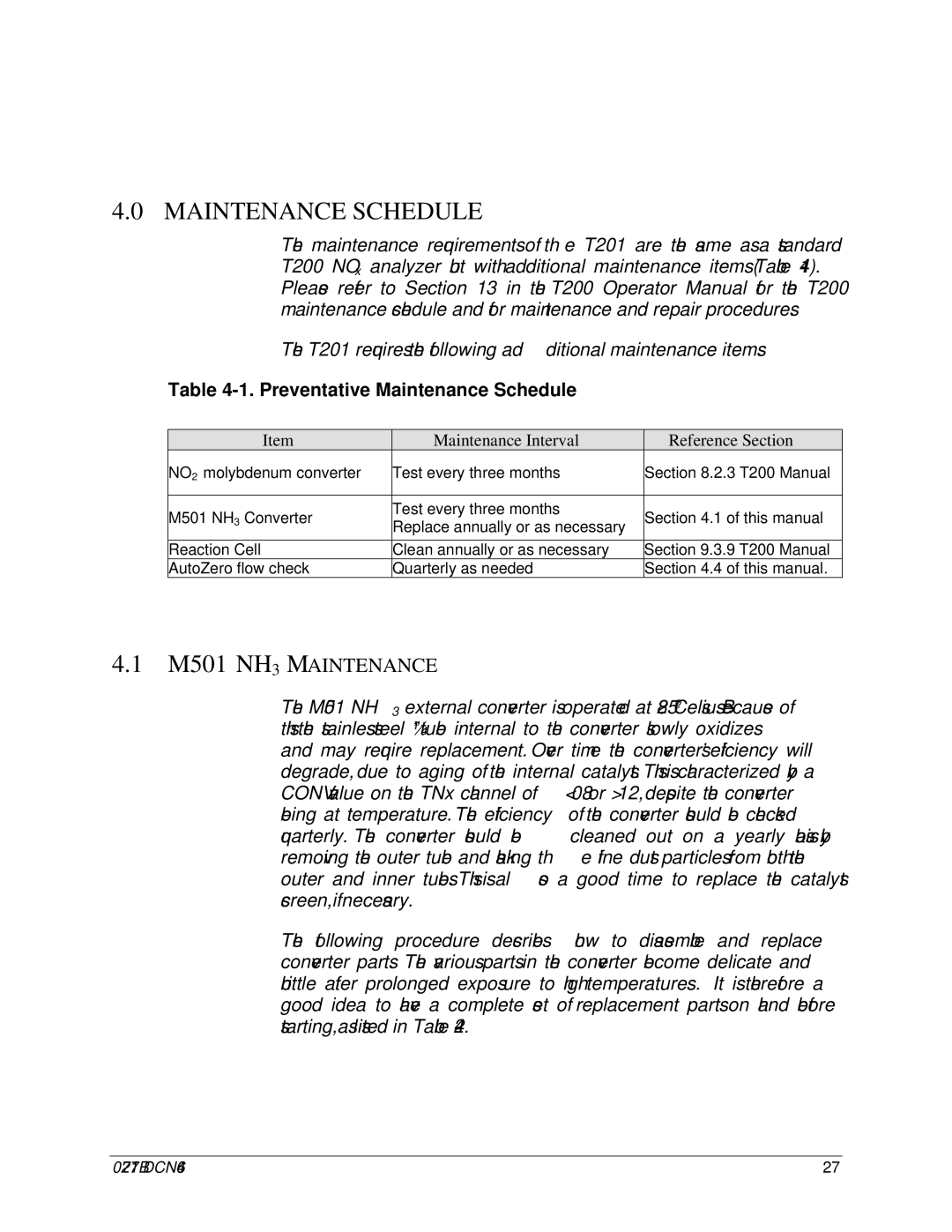

The T201 requires the following additional maintenance items.

Table 4-1. Preventative Maintenance Schedule

Item | Maintenance Interval | Reference Section | |

NO2 molybdenum converter | Test every three months | Section 8.2.3 T200 Manual | |

|

|

| |

M501 NH3 Converter | Test every three months | Section 4.1 of this manual | |

Replace annually or as necessary | |||

|

| ||

Reaction Cell | Clean annually or as necessary | Section 9.3.9 T200 Manual | |

AutoZero flow check | Quarterly as needed | Section 4.4 of this manual. |

4.1M501 NH3 MAINTENANCE

The M501 NH3 external converter is operated at 825 ºCelsius. Because of this the stainless steel ¼” tube internal to the converter slowly oxidizes and may require replacement. Over time the converter’s efficiency will degrade, due to aging of the internal catalyst. This is characterized by a CONV value on the TNx channel of < 0.8 or > 1.2, despite the converter being at temperature. The efficiency of the converter should be checked quarterly. The converter should be cleaned out on a yearly basis by removing the outer tube and shaking the fine dust particles from both the outer and inner tubes. This is also a good time to replace the catalyst screen, if necessary.

The following procedure describes how to disassemble and replace converter parts. The various parts in the converter become delicate and brittle after prolonged exposure to high temperatures. It is therefore a good idea to have a complete set of replacement parts on hand before starting, as listed in Table

07271B DCN6646 | 27 |