BOOM HOSES ROUTING

WARNING NOTE: The sudden release of hydraulic pressure could cause the sudden movement of very heavy parts. Anyone in the way of these parts could be severely hurt or killed. DO NOT ALLOW these hydraulic hoses to BREAK or BURST in order to prevent hydraulic failure Make sure the hoses do not pinch or stretch as boom moves. Measure TWICE, check TWICE then proceed with caution.

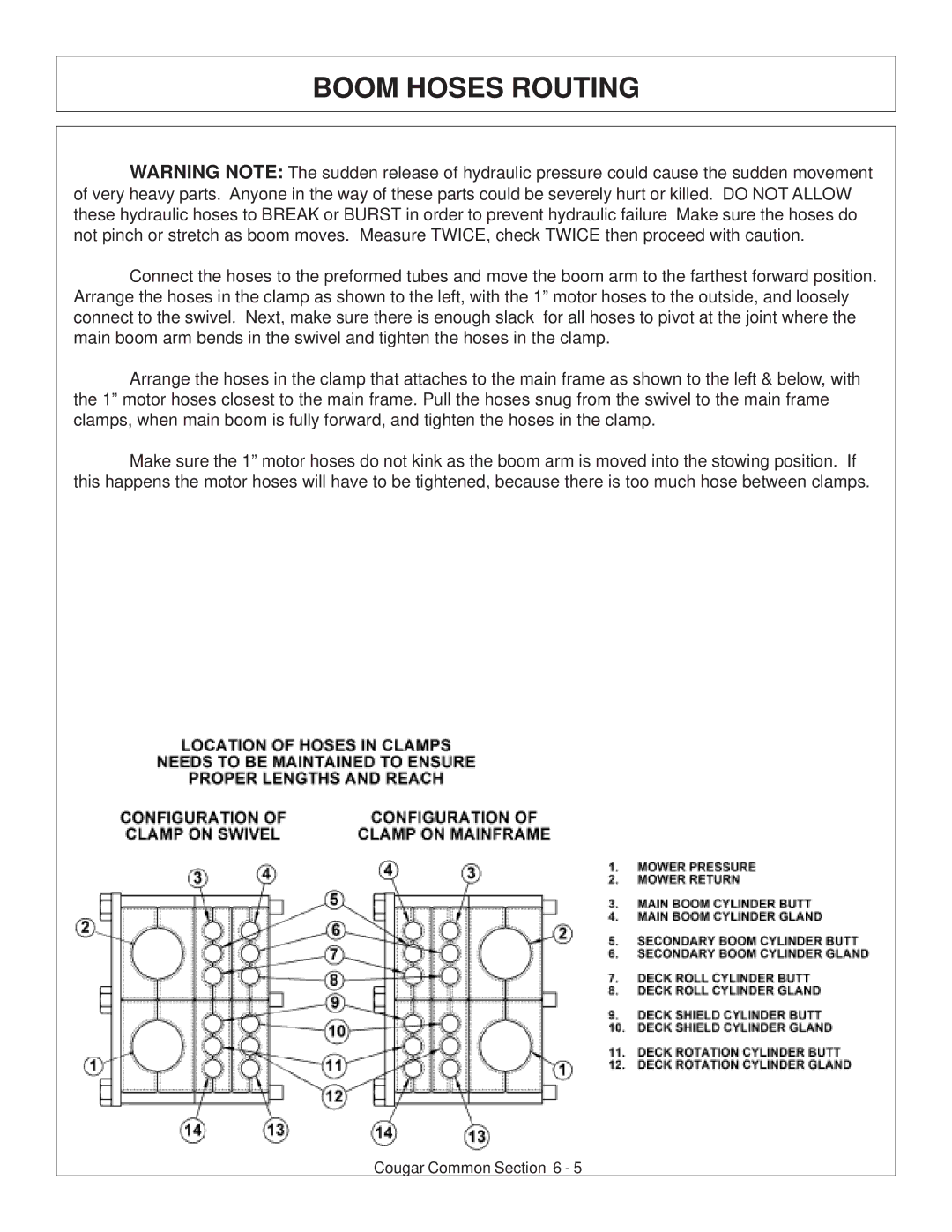

Connect the hoses to the preformed tubes and move the boom arm to the farthest forward position. Arrange the hoses in the clamp as shown to the left, with the 1” motor hoses to the outside, and loosely connect to the swivel. Next, make sure there is enough slack for all hoses to pivot at the joint where the main boom arm bends in the swivel and tighten the hoses in the clamp.

Arrange the hoses in the clamp that attaches to the main frame as shown to the left & below, with the 1” motor hoses closest to the main frame. Pull the hoses snug from the swivel to the main frame clamps, when main boom is fully forward, and tighten the hoses in the clamp.

Make sure the 1” motor hoses do not kink as the boom arm is moved into the stowing position. If this happens the motor hoses will have to be tightened, because there is too much hose between clamps.

Cougar Common Section 6 - 5