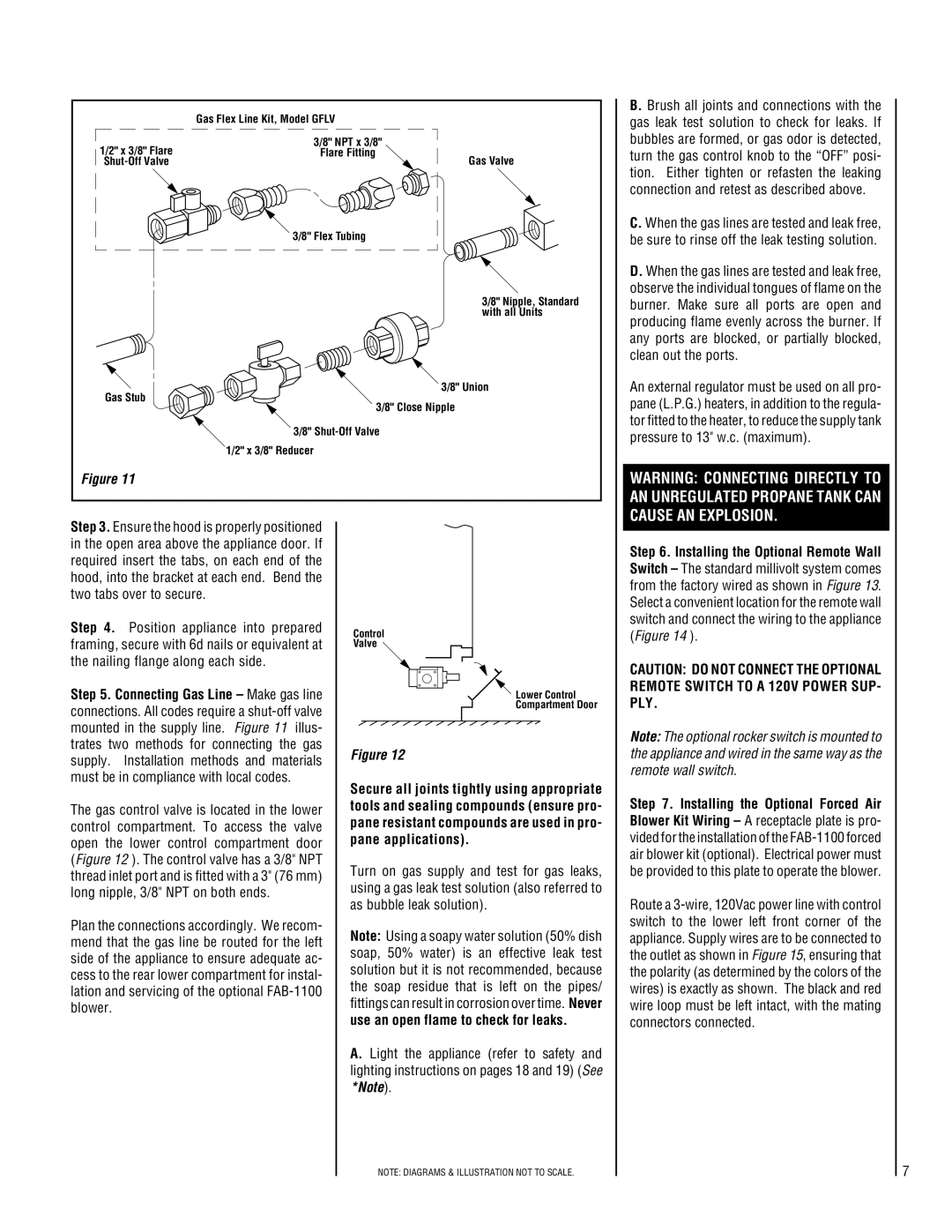

| Gas Flex Line Kit, Model GFLV | |

1/2" x 3/8" Flare | 3/8" NPT x 3/8" | |

Flare Fitting | ||

Gas Valve | ||

| 3/8" Flex Tubing | |

| 3/8" Nipple, Standard | |

| with all Units | |

Gas Stub | 3/8" Union | |

3/8" Close Nipple | ||

| ||

| 3/8" | |

| 1/2" x 3/8" Reducer | |

Figure 11 |

|

B. Brush all joints and connections with the gas leak test solution to check for leaks. If bubbles are formed, or gas odor is detected, turn the gas control knob to the “OFF” posi- tion. Either tighten or refasten the leaking connection and retest as described above.

C. When the gas lines are tested and leak free, be sure to rinse off the leak testing solution.

D. When the gas lines are tested and leak free, observe the individual tongues of flame on the burner. Make sure all ports are open and producing flame evenly across the burner. If any ports are blocked, or partially blocked, clean out the ports.

An external regulator must be used on all pro- pane (L.P.G.) heaters, in addition to the regula- tor fitted to the heater, to reduce the supply tank pressure to 13" w.c. (maximum).

WARNING: CONNECTING DIRECTLY TO AN UNREGULATED PROPANE TANK CAN CAUSE AN EXPLOSION.

Step 3. Ensure the hood is properly positioned in the open area above the appliance door. If required insert the tabs, on each end of the hood, into the bracket at each end. Bend the two tabs over to secure.

Step 4. Position appliance into prepared framing, secure with 6d nails or equivalent at the nailing flange along each side.

Step 5. Connecting Gas Line – Make gas line connections. All codes require a

The gas control valve is located in the lower control compartment. To access the valve open the lower control compartment door (Figure 12 ). The control valve has a 3/8" NPT thread inlet port and is fitted with a 3" (76 mm) long nipple, 3/8" NPT on both ends.

Plan the connections accordingly. We recom- mend that the gas line be routed for the left side of the appliance to ensure adequate ac- cess to the rear lower compartment for instal- lation and servicing of the optional

Control

Valve

Lower Control

Compartment Door

Figure 12

Secure all joints tightly using appropriate tools and sealing compounds (ensure pro- pane resistant compounds are used in pro- pane applications).

Turn on gas supply and test for gas leaks, using a gas leak test solution (also referred to as bubble leak solution).

Note: Using a soapy water solution (50% dish soap, 50% water) is an effective leak test solution but it is not recommended, because the soap residue that is left on the pipes/ fittings can result in corrosion over time. Never use an open flame to check for leaks.

A. Light the appliance (refer to safety and lighting instructions on pages 18 and 19) (See *Note).

Step 6. Installing the Optional Remote Wall Switch – The standard millivolt system comes from the factory wired as shown in Figure 13. Select a convenient location for the remote wall switch and connect the wiring to the appliance (Figure 14 ).

CAUTION: DO NOT CONNECT THE OPTIONAL REMOTE SWITCH TO A 120V POWER SUP- PLY.

Note: The optional rocker switch is mounted to the appliance and wired in the same way as the remote wall switch.

Step 7. Installing the Optional Forced Air Blower Kit Wiring – A receptacle plate is pro- vided for the installation of the

Route a

NOTE: DIAGRAMS & ILLUSTRATION NOT TO SCALE.

7